Graphene waterborne epoxy composite coating applicable to high-chlorine saturated carbon dioxide environment, and preparation method and application thereof

A carbon dioxide and composite coating technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve problems such as corrosion of metal pipes, achieve good dispersion, improve coating quality, and ensure the effect of anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention discloses a preparation method of a graphene water-based epoxy composite coating suitable for a high chlorine saturated carbon dioxide environment, comprising the following steps:

[0038] 1) Use deionized water and absolute ethanol to clean the oil stains on the metal base of 20 steel, and then use sandpaper No. 180 to No. 1500 to polish it sequentially, and then polish it to a mirror surface for later use.

[0039] 2) Using sodium carboxymethyl cellulose as a dispersant and fumed silica as an anti-sedimentation agent, add water-based epoxy emulsion to configure a composite emulsion; wherein, the amount of sodium carboxymethyl cellulose added is 0.05% of the total mass of the composite slurry %-0.2%; the addition amount of fumed silica is 0.1%-0.3% of the total mass of the composite slurry, and the water-based epoxy emulsion is E44 water-based epoxy emulsion.

[0040] 3) Adding an appropriate amount of ammonia water to the composite emulsion to adjust the...

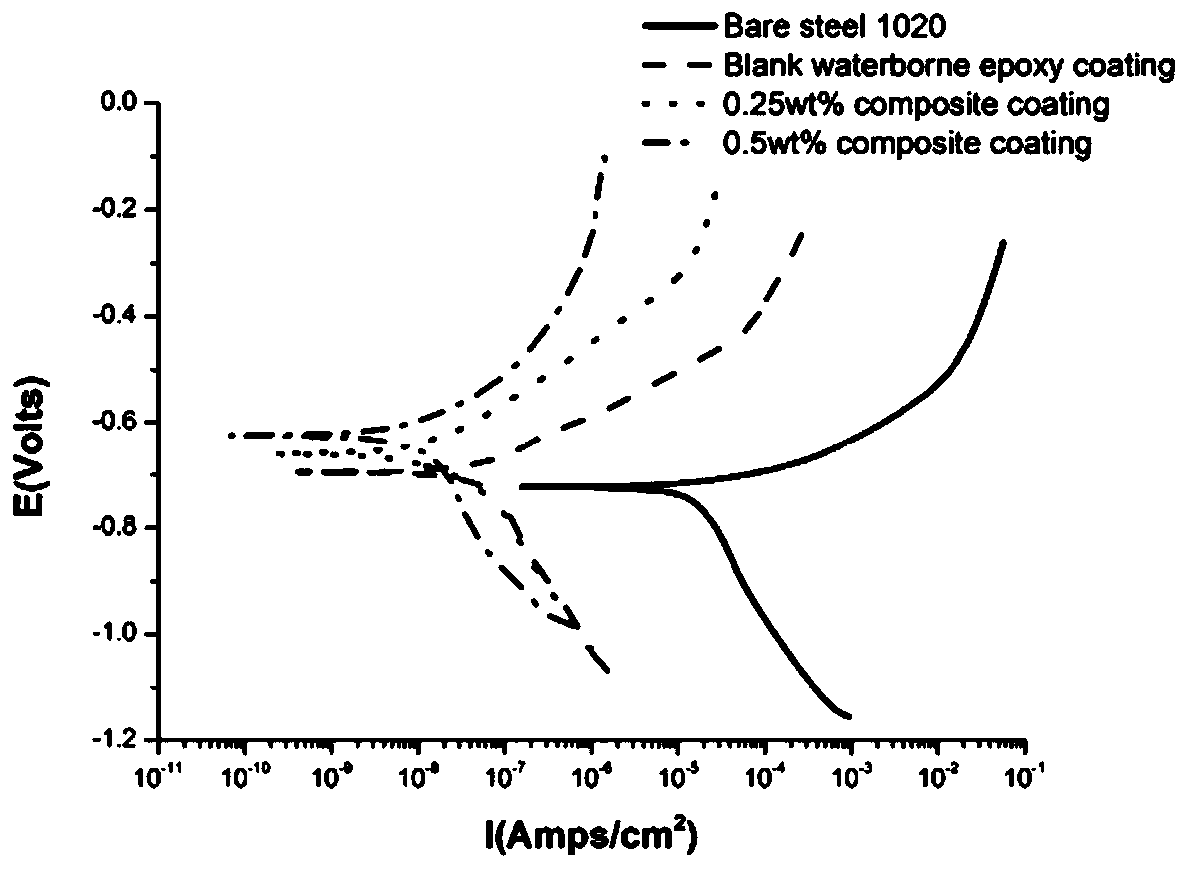

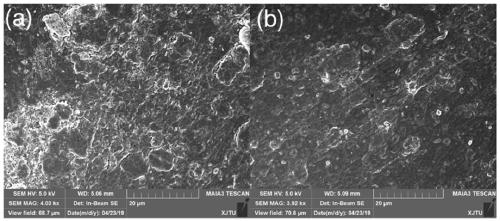

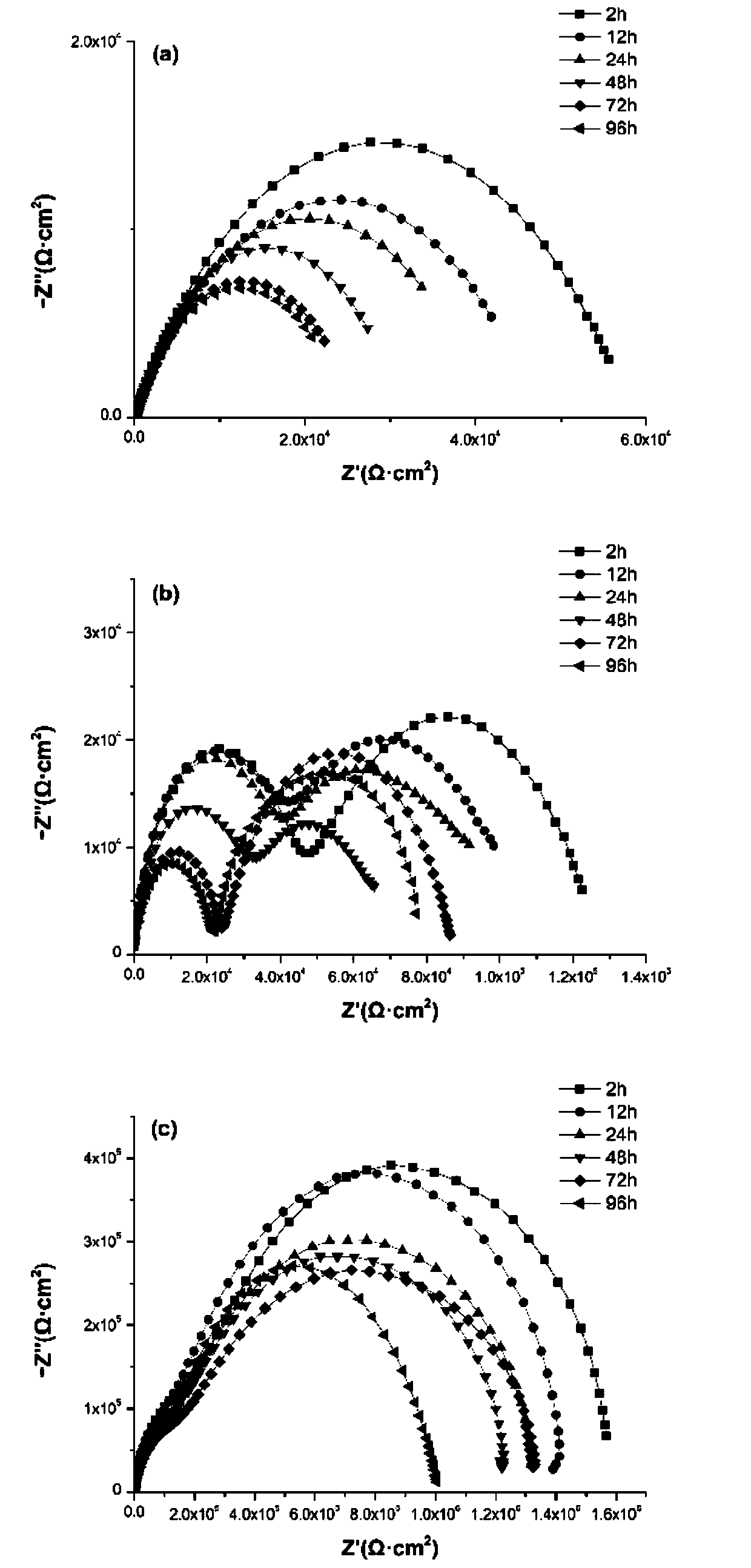

Embodiment 1

[0046] 1) Use deionized water and absolute ethanol to clean the oil stains on the metal base of 20 steel, then use sandpaper from No. 180 to No. 1500 to polish in sequence, and then polish to a mirror surface for later use;

[0047] 2) Using sodium carboxymethyl cellulose as a dispersant, the addition amount is 0.1%wt; fumed silica is used as an anti-sedimentation agent, and the addition amount is 0.15%wt, adding sodium carboxymethyl cellulose and fumed silica E44 water-based epoxy emulsion configuration composite emulsion;

[0048] 3) Add an appropriate amount of ammonia water to adjust the pH to 9, and remove a small amount of precipitate by centrifugation (centrifugation speed is 5000rpm, centrifugation time is 30min);

[0049] 4) the few-layer graphene that mass fraction is 0.25% is dissolved in the aqueous epoxy compound emulsion, adds surfactant sodium dodecyl sulfonate, and the addition of sodium dodecyl sulfonate is the number of few-layer graphene Add 8% of the mass ...

Embodiment 2

[0053] 1) Use deionized water and absolute ethanol to clean the oil stains on the metal base of 20 steel, then use sandpaper from No. 180 to No. 1500 to polish in sequence, and then polish to a mirror surface for later use;

[0054] 2) Using sodium carboxymethyl cellulose as a dispersant, the addition amount is 0.1%wt; fumed silica is used as an anti-sedimentation agent, and the addition amount is 0.15%wt, adding sodium carboxymethyl cellulose and fumed silica E44 water-based epoxy emulsion configuration composite emulsion;

[0055] 3) Add an appropriate amount of ammonia water to adjust the pH to 9, and remove a small amount of precipitate by centrifugation (centrifugation speed is 5000rpm, centrifugation time is 30min);

[0056] 4) the few-layer graphene that mass fraction is 0.5% is dissolved in the aqueous epoxy compound emulsion, adds surfactant sodium dodecyl sulfonate, and the addition of sodium dodecyl sulfonate is the number of few-layer graphene Add 8% of the mass a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com