Flame-retardant resin pouring sealant for transformer and preparation method thereof

A technology of flame retardant resin and potting adhesive, which is applied in the direction of modified epoxy resin adhesives, adhesive additives, non-polymer adhesive additives, etc., and can solve the problem of settlement and quick solidification of flame retardant resin potting adhesive fillers Low stress and heat resistance, high coefficient of linear thermal expansion, etc., to achieve the effect of improving resistance to medium penetration, solvent resistance, high temperature resistance, and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

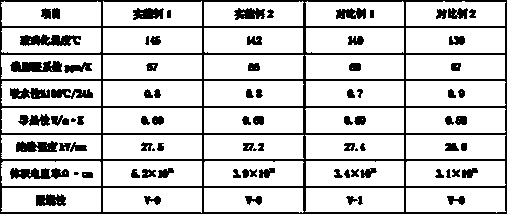

Examples

Embodiment 1

[0014] A method for preparing flame-retardant resin potting glue for transformers. The preparation method of the handicraft material includes the following processing steps: Step 1. Weigh 50 parts of phenol and 36 parts of solid formaldehyde into a reactor, and add 30 parts of xylene , Magnetic stirring at room temperature for 30 minutes, heating to 45°C, adding 2.8 parts of dipropyleneamine diluted with 5 parts of xylene dropwise with a constant pressure dropping funnel. After the dropwise addition, heating to 95°C, condensing and refluxing for 4 hours, and cooling to room temperature Stop the reaction. Extract with acetone, 0.1moL / L NaOH solution and saturated brine in turn, and finally remove the solvent by vacuum filtration to obtain a yellow viscous allyl benzoxazine monomer; step two, by weight, 138 parts of allyl benzoxazine monomer, 123 parts of o-aminostyrene, and 65 parts of solid formaldehyde were uniformly mixed and put into the reactor. After stirring at 100°C, the ...

Embodiment 2

[0018] A method for preparing a flame-retardant resin potting glue for a transformer. The preparation method of the handicraft material includes the following processing steps: Step 1. Weigh 47 parts of phenol and 36 parts of solid formaldehyde into a reactor, and add 20 parts of xylene , Magnetic stirring at room temperature for 20 minutes, heating to 40°C, adding 2.5 parts of dipropyleneamine diluted with 3 parts of xylene dropwise with a constant pressure dropping funnel. After the dropwise addition, heating to 90°C, condensing and refluxing for 3 hours, and cooling to room temperature Stop the reaction. Extract with acetone, 0.1moL / L NaOH solution and saturated brine in turn, and finally remove the solvent by vacuum filtration to obtain a yellow viscous allyl benzoxazine monomer; step two, by weight, 132 parts of allyl benzoxazine monomer, 117 parts of o-aminostyrene, and 60 parts of solid formaldehyde were uniformly mixed and put into the reactor. After stirring at 95°C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com