Graphene/polymer nanofiber composite membrane, preparation method therefor and application of graphene/polymer nanofiber composite membrane

A nanofiber film and nanofiber technology, applied in the fields of application, nanotechnology, nanotechnology, etc., can solve the problems of poor sensing performance, low sensor sensitivity, low graphene loading, etc., to improve the bonding strength, change the resistance, The effect of good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

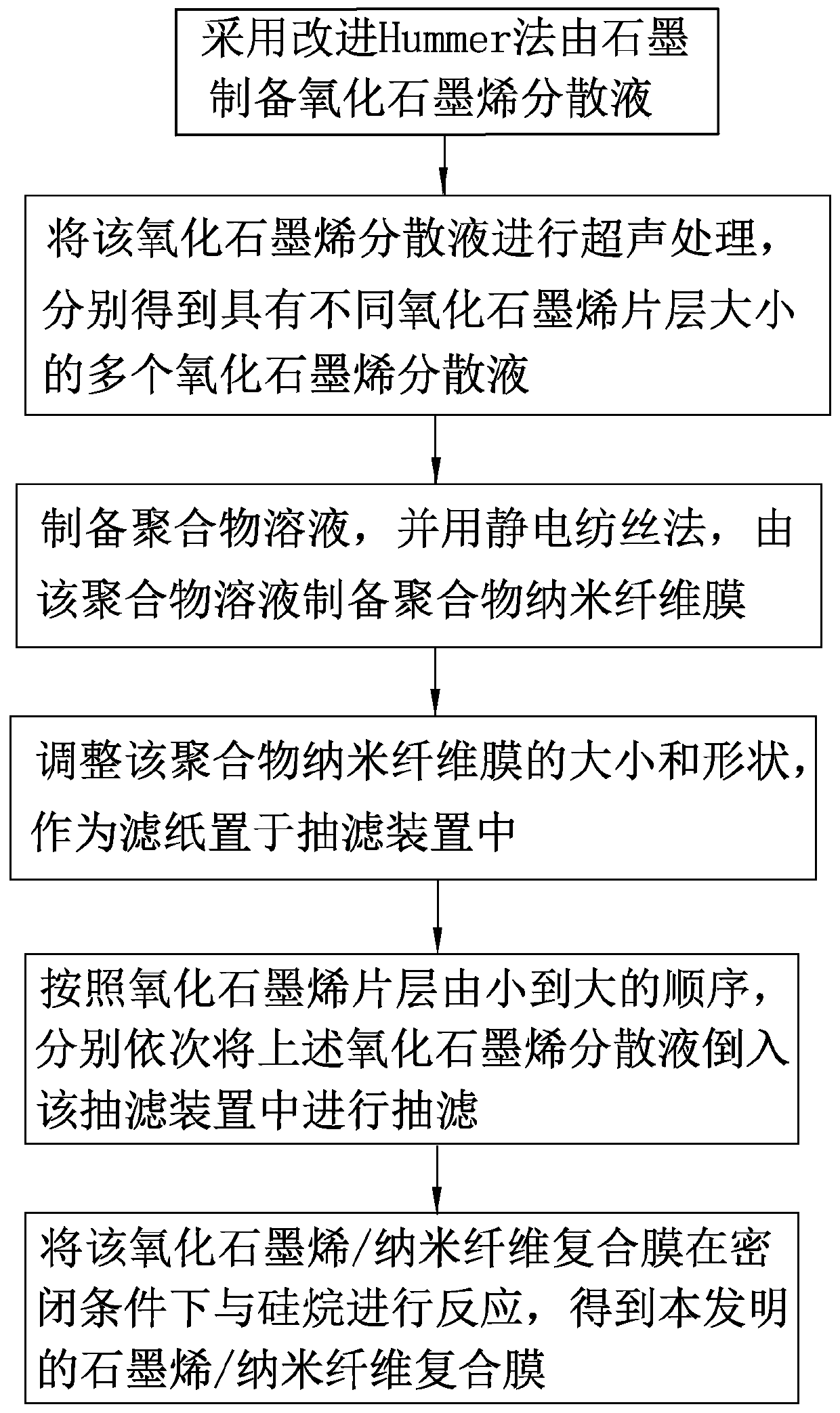

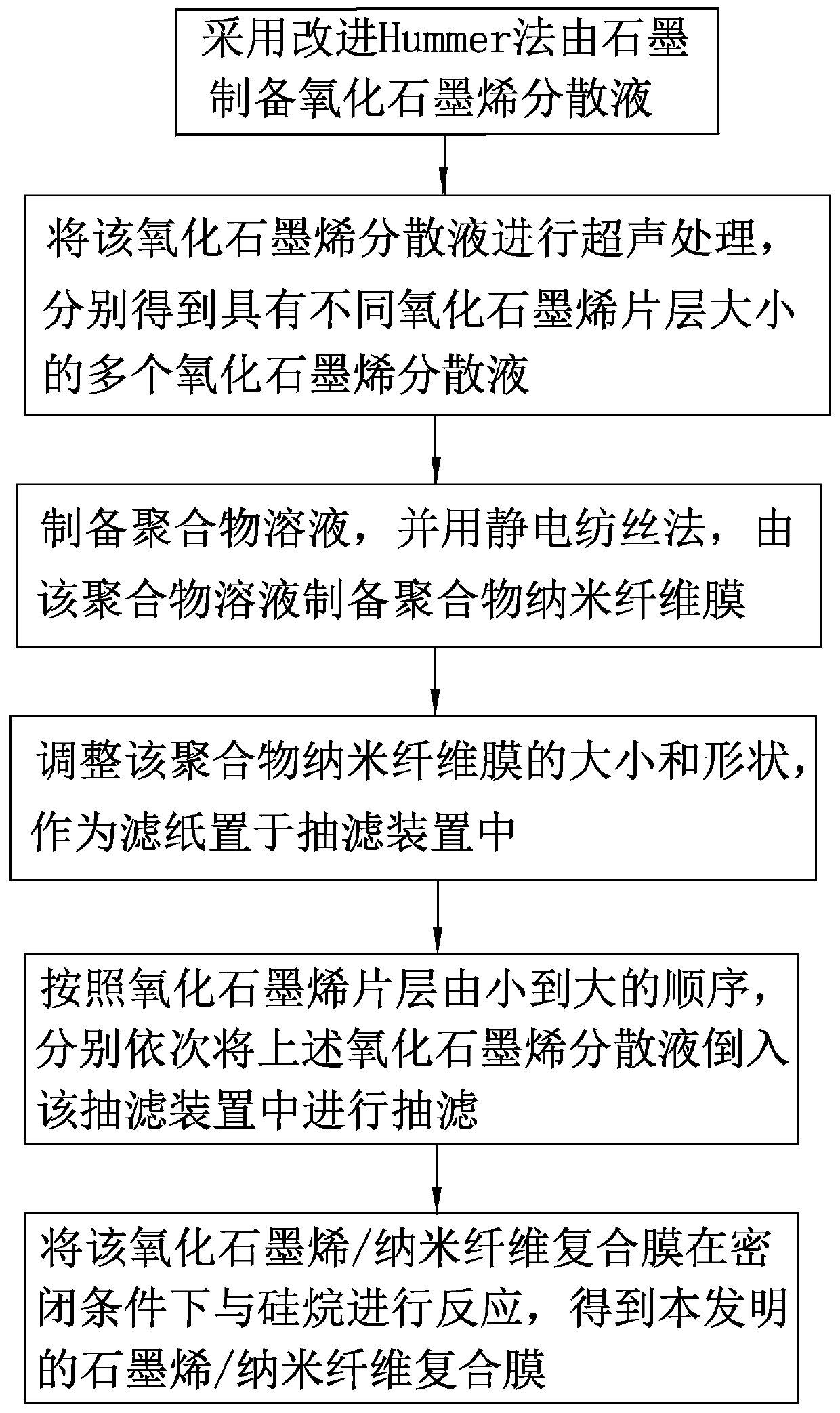

[0023] The invention provides a method for preparing a graphene / polymer nanofiber composite film, figure 1 Shown is a schematic flow chart of the preparation method, which includes the following steps: first, a graphene oxide dispersion is prepared from graphite by an improved Hummer method. Secondly, the graphene oxide dispersion is subjected to ultrasonic treatment, and different ultrasonic power and ultrasonic time are adjusted to obtain multiple graphene oxide dispersions with different graphene oxide sheet sizes. According to the order of the flakes from small to large, they are: the first graphene oxide dispersion, the second graphene oxide dispersion, ..., the Nth graphene oxide dispersion. The graphene oxide sheet size ranges from 0.2 to 5 μm. Thirdly, a polymer solution is prepared, and an electrospinning method is used to prepare a polymer nanofiber membrane from the polymer solution. Then, adjust the appropriate size and shape of the polymer nanofiber membrane obt...

Embodiment 1

[0045] Pre-oxidation: 16.8g K 2 S 2 o 8 and 16.8g P 2 o 5 Disperse in 80 mL of concentrated H at 60 °C 2 SO 4 In, slowly add 20g of graphite powder, and react at 80°C for 5h. After cooling to room temperature, it was slowly diluted with deionized water and allowed to stand to separate layers. After the supernatant was discarded, it was suction-filtered with a polytetrafluoroethylene filter membrane with a pore size of 0.22 μm, and the upper filter cake was washed with 3 L of deionized water and then dried naturally to obtain pre-oxidized graphite.

[0046] Oxidation: Disperse the pre-oxidized graphite in 460 mL of concentrated H 2 SO 4 and keep stirring in an ice-salt bath to lower the temperature to 0-3°C. Slowly add 60g KMnO with stirring 4 , and always keep the temperature below 5°C. Then the mixed reaction solution was heated to 35° C. and stirred for 2 h, diluted with 1.5 L of deionized water, then heated to 85° C. and stirred for 2.5 h. Add 1.5L deionized wat...

Embodiment 2

[0054] The steps of the pre-oxidation, oxidation, centrifugation, washing, ultrasonic treatment, and preparation of the pressure sensor in Example 2 are the same as those in Example 1. The differences are as follows:

[0055] Electrospinning: Take the thermoplastic polyurethane N,N-dimethylformamide solution with a concentration of 15% and place it in a 10mL syringe equipped with a metal needle with an outer diameter of 0.7mm. The resulting product was collected in a plate receiver. Electrospinning was performed at a voltage of 12 kV, a flow rate of 0.5 mL / h, and a receiving distance of 15 cm. In order to ensure that the polymer nanofibers are evenly collected, the motion control system of the nozzle is used to control the nozzle to reciprocate within the range of 5-10 cm, and the processing duration is 12 hours.

[0056] Suction filtration: take the obtained nanofiber membrane as filter paper and place it in a suction filtration device, pour 50mL of graphene oxide dispersio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com