Metal organic framework with polymer grafted on surface and preparation method thereof

A metal-organic framework and surface grafting technology, applied in separation methods, chemical instruments and methods, medical preparations with inactive ingredients, etc. Improve the effect of practical application, the effect of fewer method steps and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

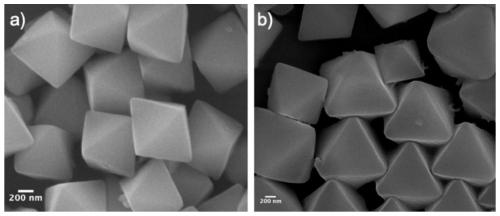

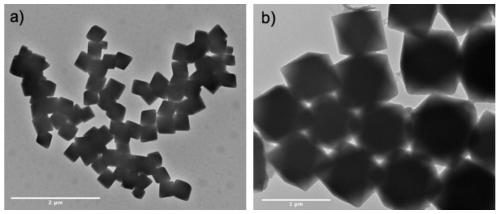

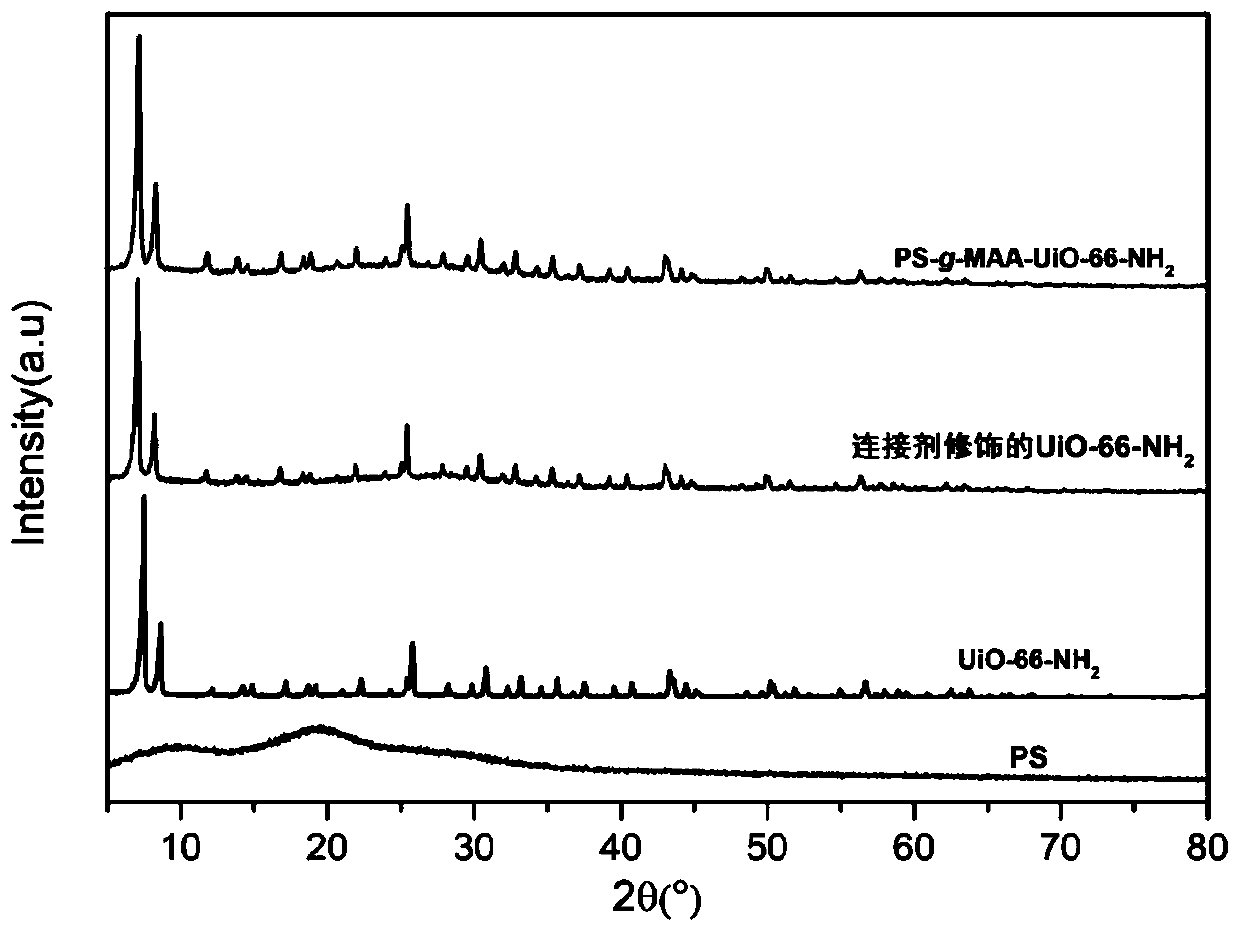

[0042] Using methacrylic anhydride as linker in UiO-66-NH 2 Surface grafted polystyrene, it comprises the following steps:

[0043] 1) Add UiO-66-NH 2 (56mg) ultrasonically dispersed in CH 2 Cl 2 (8 mL), to the resulting solution was added methacrylic anhydride (500 μL). The reaction system was placed in a constant temperature water bath at 25° C. and stirred for 2 days at a stirring speed of 200 rpm. The product was obtained by suction filtration under reduced pressure and washed with CH 2 Cl 2 Wash 3 times. Dry in a vacuum oven at 45°C for 48 hours to obtain a light yellow solid, which is UiO-66-NH modified with methacrylic anhydride linker 2 (MAA-UiO-66-NH 2 ).

[0044] 2) Add the MAA-UiO-66-NH obtained in step 1) into the three-necked flask 2 (50mg) and anhydrous acetonitrile (26ml), sonicate at room temperature for 0.5h. Then, styrene (25ml) was added into the three-neck flask under nitrogen. Nitrogen gas continued to flow through the whole system for 20 minut...

Embodiment 2

[0050] Using acrylic anhydride as linking agent in MIL-125(Ti)-NH 2 Surface grafting polymethyl methacrylate, it comprises the following steps:

[0051] 1) MIL-125(Ti)-NH 2 (48 mg) was ultrasonically dispersed in acetonitrile (12 mL), and acrylic anhydride (500 µL) was added to the resulting solution. The reaction system was placed in a constant temperature water bath at 25° C. and stirred for 3 days at a stirring speed of 300 rpm. The product was obtained by suction filtration under reduced pressure and washed 4 times with acetonitrile. Dry in a vacuum oven at 80°C for 6 hours to obtain a yellow solid, which is MIL-125(Ti)-NH modified with acrylic anhydride linker 2 (AA-MIL-125(Ti)-NH 2 ).

[0052] 2) Add AA-MIL-125(Ti)-NH obtained in step 1) into the three-necked flask 2 (50mg) and anhydrous acetonitrile (24ml), sonicated at room temperature for 1h. Then methyl methacrylate (24ml) was added into the three-necked flask under nitrogen. The whole system continued to flo...

Embodiment 3

[0055] Using acrylic anhydride as linking agent in MIL-101(Fe)-NH 2 Surface grafted polystyrene, it comprises the following steps:

[0056] 1) MIL-101(Fe)-NH 2 (48 mg) was ultrasonically dispersed in acetonitrile (12 mL), and acrylic anhydride (500 µL) was added to the resulting solution. The reaction system was placed in a constant temperature water bath at 25° C. and stirred for 3 days at a stirring speed of 350 rpm. The product was obtained by suction filtration under reduced pressure and washed 5 times with acetonitrile. Dry in a vacuum oven at 60°C for 24 hours to obtain a brown solid, which is MIL-101(Fe)-NH modified with acrylic anhydride linker 2 (AA-MIL-101(Fe)-NH 2 ).

[0057] 2) Add AA-MIL-101(Fe)-NH obtained in step 1) into the three-necked flask 2 (50mg) and acetonitrile (25ml), sonicate at room temperature for 2h. Then, styrene (27ml) was added into the three-necked flask under nitrogen. The whole system continued to flow nitrogen for 35 minutes. After a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com