Application of novel MIL-53(Fe) based catalyst in removal of antibiotics in water

A catalyst and antibiotic technology, applied in the field of metal-organic framework materials, can solve the problems of MIL-53 morphology and structure changes, steric hindrance increase, etc., to increase light absorption performance and structural stability, prevent aggregation, and good photocatalysis Performance and Stability Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

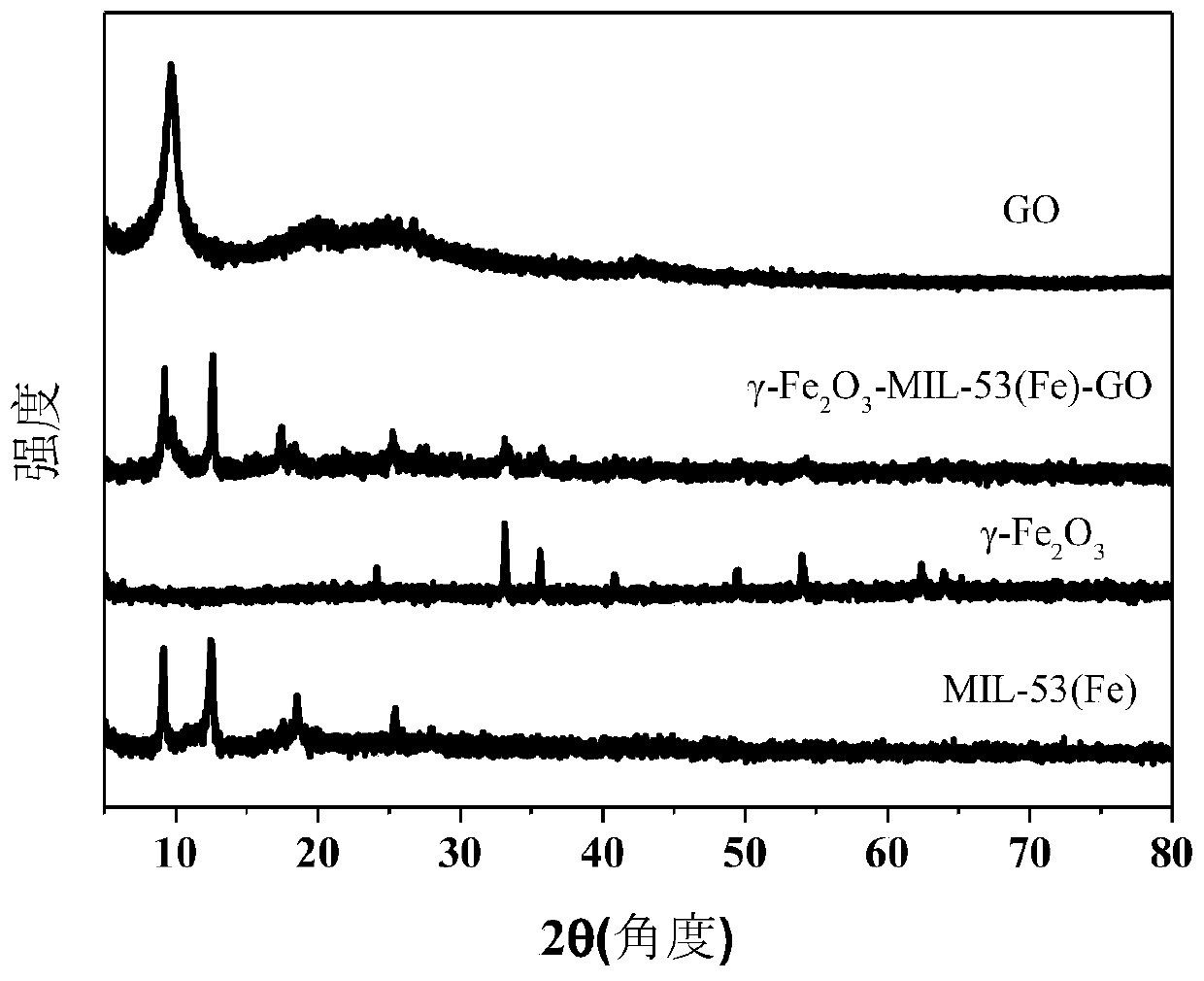

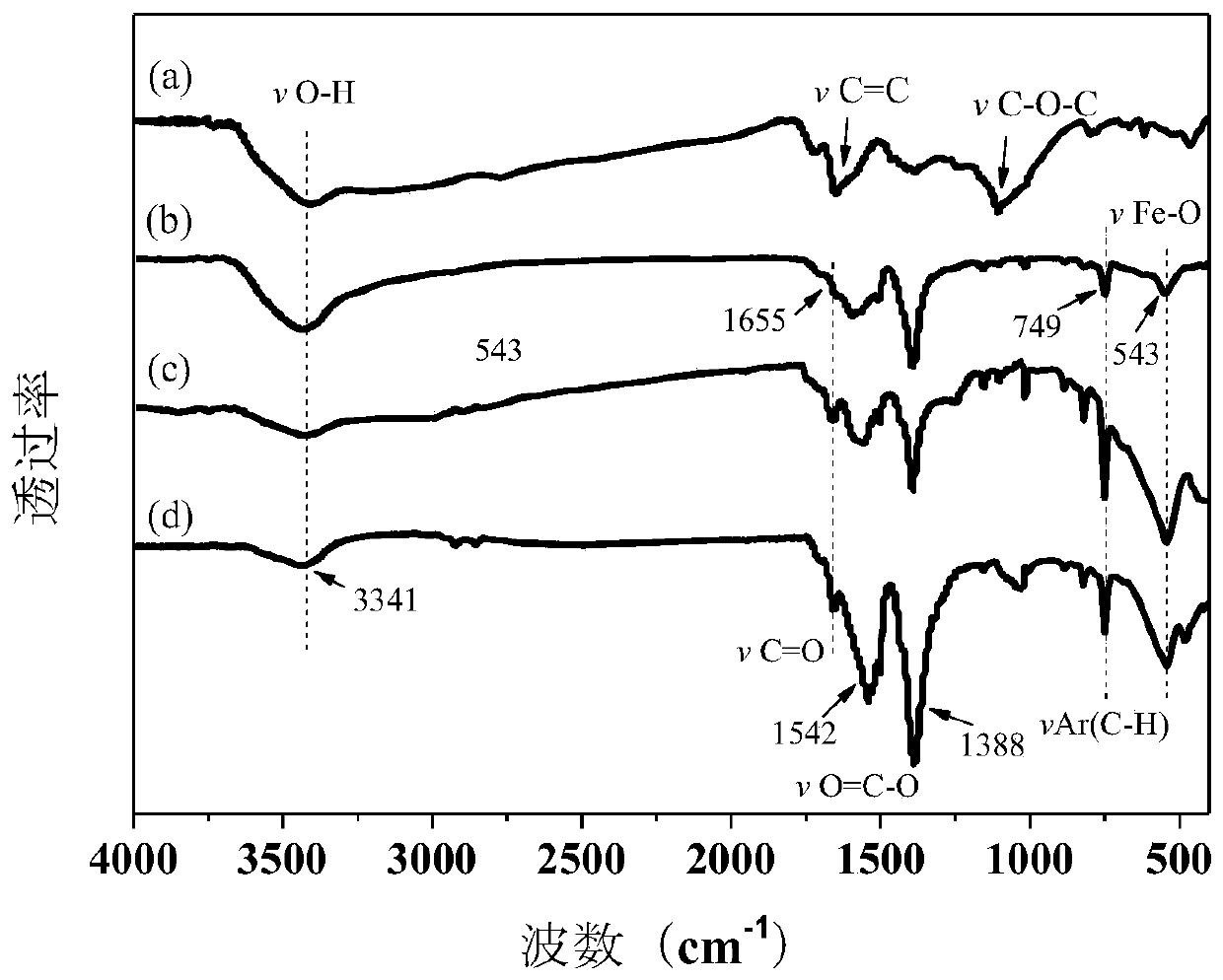

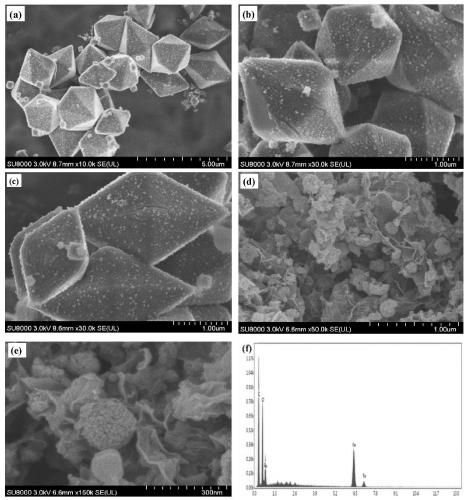

[0030] Will contain 2.5mmol FeCl 3 ·6H 2 25ml of N,N-dimethylformamide solution of O was added dropwise to 4ml of N,N-dimethylformamide suspension containing graphene oxide at a concentration of 10mg / L, wherein the mass of graphene oxide accounted for 20% of the mass of MIL-53(Fe) in medium, after sonication, 25ml of N,N-dimethylformamide solution containing 100mM terephthalic acid was added dropwise to the above mixture and then sonicated for 2h, then 0.6mmol of FeCl 3 ·6H 2 O and 250 μl of ethylenediamine were dissolved in 5 ml of N,N-dimethylformamide at a material ratio of 3:1, and finally, the mixed solution was added dropwise to the previous mixture, and sonicated to a homogeneous mixture. The resulting mixture was transferred to a polytetrafluoroethylene-lined autoclave and kept at 150 °C for 15 h. After cooling to room temperature, it was centrifuged at 8000 r / min for 5 min and washed with N,N-dimethylformamide and methanol respectively. Three times, vacuum drying a...

Embodiment 2

[0032] Will contain 2.5mmol FeCl 3 ·6H 2 25ml of N,N-dimethylformamide solution of O was added dropwise to 10ml of graphene oxide-containing N,N-dimethylformamide suspension at a concentration of 10mg / L, and the mass of GO accounted for MIL in the composite material. 50% of the mass of -53(Fe), after sonication, add 25ml of N,N-dimethylformamide solution containing 100mM terephthalic acid dropwise to the above mixture and then sonicate for 2h, then add 0.6mmol of FeCl 3 ·6H 2 O and 250 μl of ethylenediamine were dissolved in 5 ml of N,N-dimethylformamide at a material ratio of 3:1, and finally, the mixed solution was added dropwise to the previous mixture, and sonicated to a homogeneous mixture. The resulting mixture was transferred to a polytetrafluoroethylene-lined autoclave and kept at 150 °C for 15 h. After cooling to room temperature, it was centrifuged at 8000 r / min for 5 min and washed three times with N-dimethylformamide and methanol. , dried in vacuum at 80°C for 1...

Embodiment 3

[0034] Will contain 2.5mmol FeCl 3 ·6H 2 25ml of N,N-dimethylformamide solution of O was added dropwise to 16ml of graphene oxide-containing N,N-dimethylformamide suspension at a concentration of 10mg / L, and the mass of GO accounted for MIL in the composite material. 50% of the mass of -53(Fe), after sonication, add 25ml of N,N-dimethylformamide solution containing 100mM terephthalic acid dropwise to the above mixture and then sonicate for 2h, then add 0.6mmol of FeCl 3 ·6H 2 O and 250 μl of ethylenediamine were dissolved in 5 ml of N,N-dimethylformamide at a material ratio of 3:1, and finally, the mixed solution was added dropwise to the previous mixture, and sonicated to a homogeneous mixture. The resulting mixture was transferred to a polytetrafluoroethylene-lined autoclave and kept at 150 °C for 15 h. After cooling to room temperature, it was centrifuged at 8000 r / min for 5 min and washed three times with N-dimethylformamide and methanol. , dried in vacuum at 80°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com