A kind of preparation method of water-based acrylic resin modified starch-based hydrogel water retention agent granules

A water-based acrylic acid, starch-based technology, applied in chemical instruments and methods, soil conditioning materials, agricultural machinery and implements, etc., can solve the problems of poor reaction accessibility, long time, short decomposition time, etc., and achieve good dissolution and storage. , sufficient water and fertilizer, the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

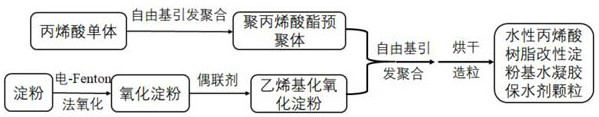

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 A kind of preparation method of water-based acrylic resin modified starch-based hydrogel water-retaining agent particles

[0047] Include the following steps:

[0048] (1) Preparation of oxidized starch dispersion

[0049] Add 490 g of water and 210 g of corn starch to a 1 L five-necked flask, stir evenly at a speed of 150 r / min, add dilute sulfuric acid to adjust the pH to 3.0, heat up to 50 °C, add 15 mL of 0.1 mol / L ferrous salt complex Combined solution (molar ratio of ferrous sulfate and sodium tartrate 1:2), insert electrode, graphite electrode as anode, titanium electrode as cathode, calomel electrode as reference, connect electrochemical analysis system for constant current electrolysis, current density 10 ~30 A / m 2 . Add 27.3 g of hydrogen peroxide dropwise for about 1 h, during which the temperature rises rapidly. After the temperature is stable, adjust the temperature to 60 °C ~ 70 °C, keep the temperature for 90 min, turn off the electrochemi...

Embodiment 2

[0057] Embodiment 2 A kind of preparation method of water-based acrylic resin modified starch-based hydrogel water-retaining agent particles

[0058] Include the following steps:

[0059] (1) Preparation of oxidized starch dispersion

[0060] Add 490 g of water and 210 g of potato starch to a 1 L five-necked flask, stir evenly at a speed of 150 r / min, add dilute sulfuric acid to adjust the pH to 3.0, heat up to 50 °C, add 18 mL of 0.1 mol / L ferrous salt complex The mixed solution (molar ratio of ferrous sulfate and sodium citrate is 1:2), inserted into the electrode, the graphite electrode is the anode, the titanium electrode is the cathode, and the calomel electrode is the reference, and the electrochemical analysis system is connected for constant current electrolysis. 10~30A / m 2 . Add 31.5 g of hydrogen peroxide dropwise for about 1 h, during which the temperature rises rapidly. After the temperature is stable, adjust the temperature to 60 °C ~ 70 °C, keep the temperatur...

Embodiment 3

[0067] Embodiment 3 A kind of preparation method of water-based acrylic resin modified starch-based hydrogel water-retaining agent particles

[0068] Include the following steps:

[0069] (1) Preparation of oxidized starch dispersion

[0070] Add 490 g of water and 210 g of tapioca starch to a 1 L five-neck flask, stir evenly at a speed of 150 r / min, add dilute sulfuric acid to adjust the pH to 3.0, heat up to 50 °C, add 10 mL of 0.1 mol / L ferrous salt complex Combined solution (molar ratio of ferrous sulfate and sodium oxalate 1:2), insert electrode, graphite electrode as anode, titanium electrode as cathode, calomel electrode as reference, connect electrochemical analysis system for constant current electrolysis, current density 10 ~30 A / m 2 . Add 21.0 g of hydrogen peroxide dropwise for about 1 h, during which the temperature rises rapidly. After the temperature is stable, adjust the temperature to 60 °C ~ 70 °C, keep the temperature for 90 min, turn off the electrochemi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com