A kind of transparent laser welding endothermic PC plastic and preparation method thereof

A laser welding and transparent technology, which is applied in the field of transparent laser welding heat-absorbing PC plastics and its preparation, can solve the problems of inability to realize the transparency of the weld seam, poor laser welding effect, and low welding strength, and achieve good laser fusion welding effect , low cost, good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a preparation method for transparent laser welding heat-absorbing PC plastic described in the above technical solution, comprising the following steps:

[0029] Stir and mix PC resin, compatibilizer, lubricant, nano metal oxide and antioxidant according to the ratio of raw materials to obtain a premix;

[0030] The premixed material is fed into an extruder through a main feeding port for melt extrusion to obtain a transparent laser-welded heat-absorbing PC plastic.

[0031] In the present invention, it is sufficient to stir and mix the raw materials evenly, and there is no requirement on the stirring rate. In the present invention, the screw speed of the twin-screw extruder is preferably 300-400 r / min, more preferably 350 r / min. In the present invention, the vacuum degree during extrusion is preferably -0.8 to -0.5 MPa, more preferably -0.65 MPa. In the present invention, the barrel temperature of the extruder is preferably 270-290°...

Embodiment 1

[0042] A transparent laser welding heat-absorbing PC plastic, prepared from the following components: PC Covestro Markolon 280598.9kg, gallium oxide (D50=50nm) 0.3kg, PETS 0.1kg, antioxidant 1680.35kg, antioxidant 10760.35kg.

[0043] The preparation method of the above-mentioned transparent laser welding endothermic PC plastic comprises the following steps:

[0044] Stir and mix PC resin, lubricant, nano metal oxide and antioxidant to obtain a premix;

[0045] The premixed material is fed into the extruder through the main feeding port for melt extrusion, the screw speed of the twin-screw extruder is controlled at 350r / min, the barrel temperature is 280°C, and the extrusion vacuum is -0.65MPa , to obtain transparent laser welding endothermic PC plastic.

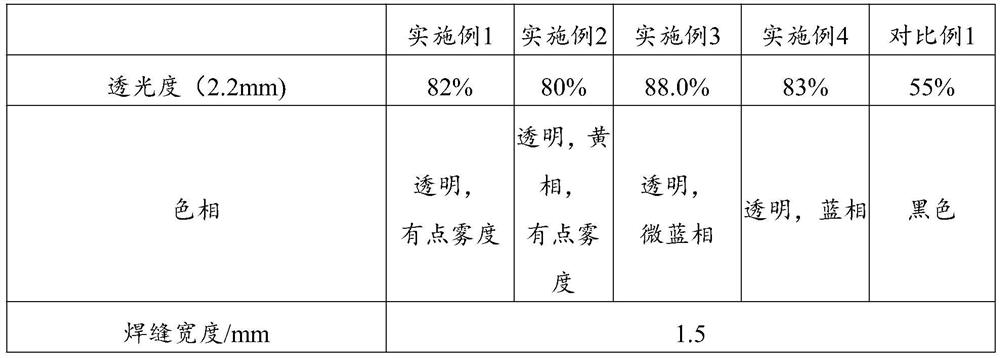

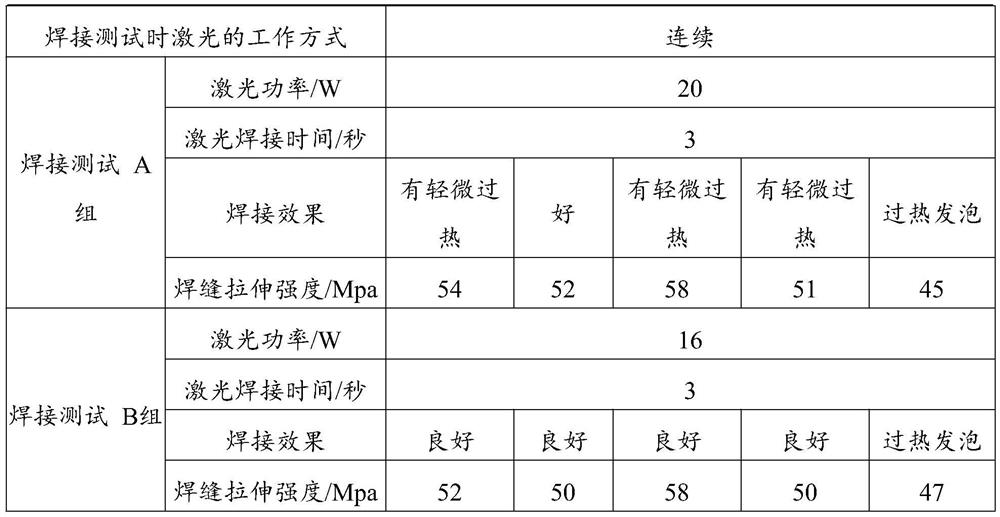

[0046] The transparent laser welding heat-absorbing PC plastic prepared in Example 1 was used to measure the transparency and perform a welding test. The test results are shown in Table 1.

Embodiment 2

[0048] A transparent laser welding heat-absorbing PC plastic, the preparation raw materials are the following components:

[0049] Sabic141R 98.7kg, gallium oxide (D50=50nm) 0.3kg, indium oxide (D50=50nm) 0.3kg, PETS1kg, antioxidant 1680.35kg, antioxidant 10760.35kg.

[0050] The preparation method of the above-mentioned transparent laser welding endothermic PC plastic comprises the following steps:

[0051] Stir and mix PC resin, lubricant, nano metal oxide and antioxidant to obtain a premix;

[0052] The premixed material is fed into the extruder through the main feeding port for melt extrusion, the screw speed of the twin-screw extruder is controlled at 350r / min, the barrel temperature is 280°C, and the extrusion vacuum is -0.65MPa , to obtain transparent laser welding endothermic PC plastic.

[0053] The transparency of the transparent laser-welded endothermic PC plastic prepared in Example 2 was measured and the welding test was performed. The test results are shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com