A method for preparing high-strength molded coke by cold pressing

A cold forming, high-strength technology, applied in building components, building insulation materials, construction, etc., can solve problems such as inability to provide high-temperature strength, health hazards to workers, loss of cohesion, etc., to improve high-temperature performance instability, Strengthen the anti-oxidation ability and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

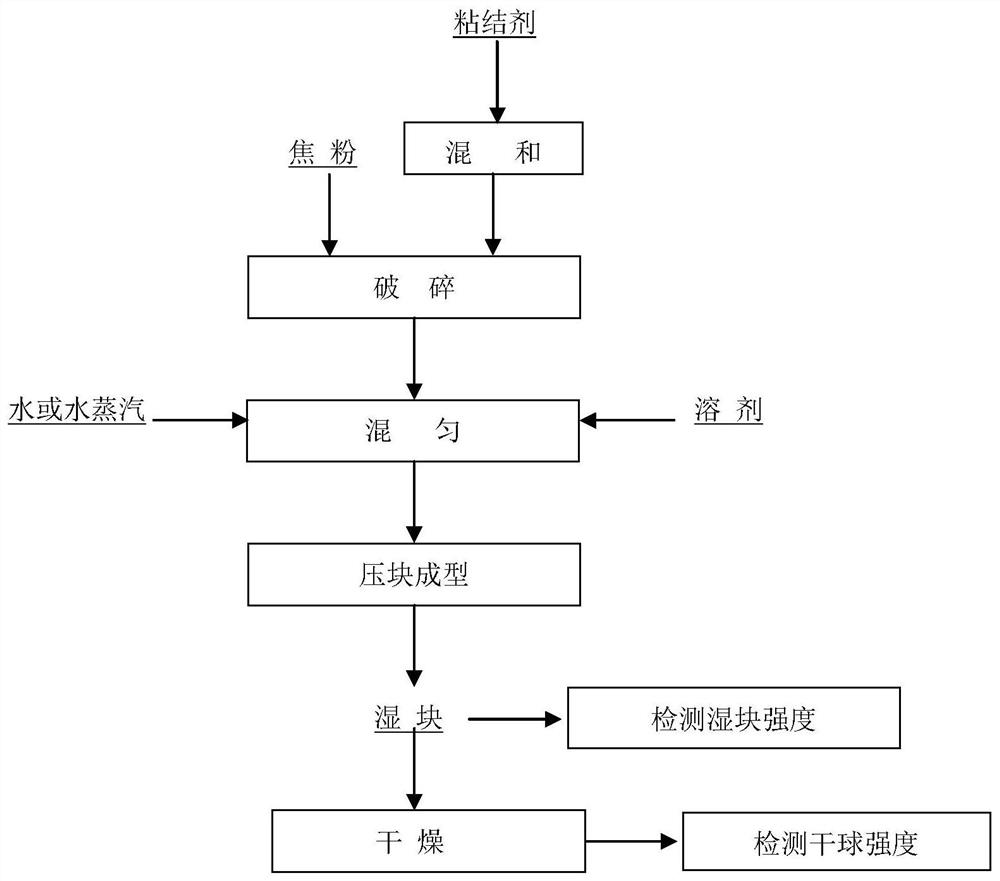

[0031] A method for preparing high-strength form coke by cold pressing, characterized in that it comprises the following specific steps:

[0032] (1) Use a crusher to crush the coke powder to a particle size of less than 3mm;

[0033] (2) Mix the binder components, stir and mix well. The binder components include the following mass proportions: 0-20 parts of normal temperature binder, 60-80 parts of asphalt, 0-5 parts of asphalt modifier, and the strength of the coke 0-10 parts of stabilizer, 0-2 parts of starch gelatinization modifier;

[0034] (3) In the crusher, mix coke powder and binder components, adjust the ratio of coke powder and binder components, and the total ratio of binder is 8.6%-10.7% of the mass of coke powder;

[0035] (4) In the mixer, mix coke powder and binder components, add water and steam to obtain the final material, the temperature of the material at the outlet of the mixer is required to be 70-90°C, and the moisture content of the final material is ...

Embodiment 2

[0041] Example 2: The raw materials are metallurgical coke powder, 20 parts of cornstarch, 60 parts of high-temperature pitch, 4 parts of artificial graphite, 2 parts of sodium hydroxide, the total amount of binder is 8.6% of the mass of metallurgical coke, and others are the same as in Example 1. The coke drop strength is 7 times (1m) -1 , the cold strength is 1230N, and the high temperature compressive strength at 900°C is 1280N. The ash content of molded coke is 14.13%, volatile matter is 5.15%, fixed carbon is 78.53%, and the rest is water.

Embodiment 3

[0042] Example 3: The raw materials are metallurgical coke powder, 20 parts of cornstarch, 60 parts of high-temperature asphalt, 10 parts of magnesium oxide, 2 parts of sodium hydroxide, the total amount of binder is 9.2% of the mass of metallurgical coke, and the others are the same as in Example 1. The coke drop strength is 8 times (1m) -1 , the cold strength is 1280N, and the high temperature compressive strength at 900°C is 1210N. The molded coke has 14.54% ash, 5.93% volatile matter, 78.26% fixed carbon, and the rest is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com