A method for improving production efficiency of l-tryptophan

A technology for production efficiency and tryptophan, which is applied in the field of improving the production efficiency of L-tryptophan, can solve the problems of bacterial strain death and difficult operation, and achieve the effect of increasing production, acid production rate and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for improving L-tryptophan production efficiency, comprising the steps of:

[0037] The components of the fermentation medium are: glucose 20g / L, dipotassium hydrogen phosphate 9g / L, yeast extract 5g / L, citric acid 4.6g / L, ammonium sulfate 1.8g / L, magnesium sulfate heptahydrate 1.6g / L, Choline chloride 0.4g / L, ferrous sulfate heptahydrate 65mg / L, biotin 0.2mg / L;

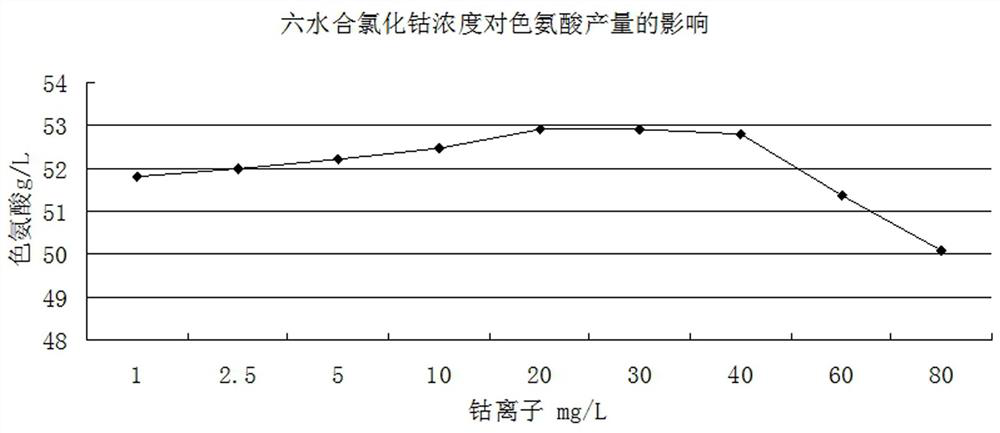

[0038] The components of nutrient solution A are: 20 mg / L of cobalt chloride hexahydrate, 10 g / L of urea;

[0039]The components of nutrient solution B are: glucose 100g / L, indole 1g / L, inositol 0.5g / L, phenylalanine 0.5g / L, tyrosine 0.4g / L;

[0040] Taking the Escherichia coli strain E.coli TRTH as an example, the seed solution (OD 600 value of 11.2) into a 1000L fermenter equipped with 600L fermentation medium, the culture temperature is 36.8°C, the dissolved oxygen is 20%, and 25% ammonia water is automatically added by numerical control to maintain the system pH in the tank at 7.0-7.2. Add a de...

Embodiment 2

[0044] A method for improving L-tryptophan production efficiency, comprising the steps of:

[0045] The components of the fermentation medium are: glucose 20g / L, dipotassium hydrogen phosphate 9g / L, yeast extract 5g / L, citric acid 4.6g / L, ammonium sulfate 1.8g / L, magnesium sulfate heptahydrate 1.6g / L, Choline chloride 0.4g / L, ferrous sulfate heptahydrate 65mg / L, biotin 0.2mg / L;

[0046] The components of nutrient solution A are: 30 mg / L of cobalt chloride hexahydrate, 15 g / L of urea;

[0047] The components of nutrient solution B are: glucose 100g / L, indole 1g / L, inositol 0.5g / L, phenylalanine 0.4g / L, tyrosine 0.3g / L;

[0048] Taking the Escherichia coli strain E.coli TRTH as an example, the seed solution (OD 600 value of 11.8) into a 1000L fermenter equipped with 600L fermentation medium, the culture temperature is 36.8°C, the dissolved oxygen is 20%, and 25% ammonia water is automatically added by numerical control to maintain the system pH in the tank at 7.0-7.2. Add a d...

Embodiment 3

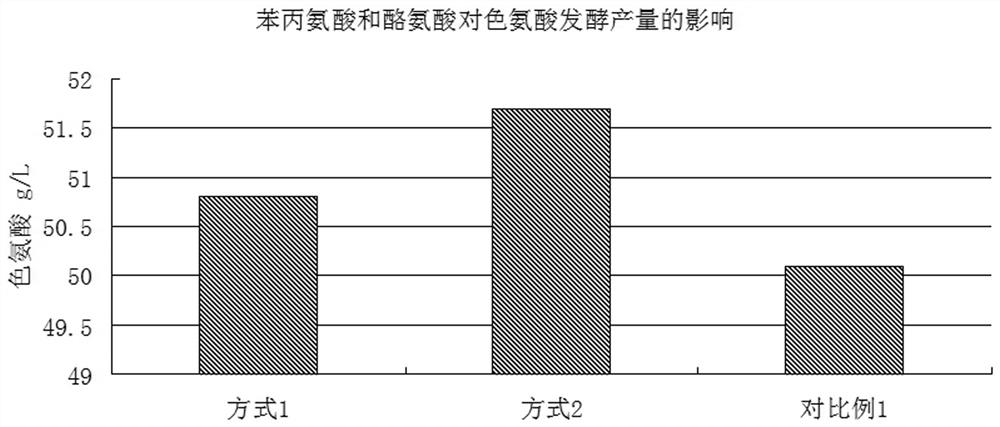

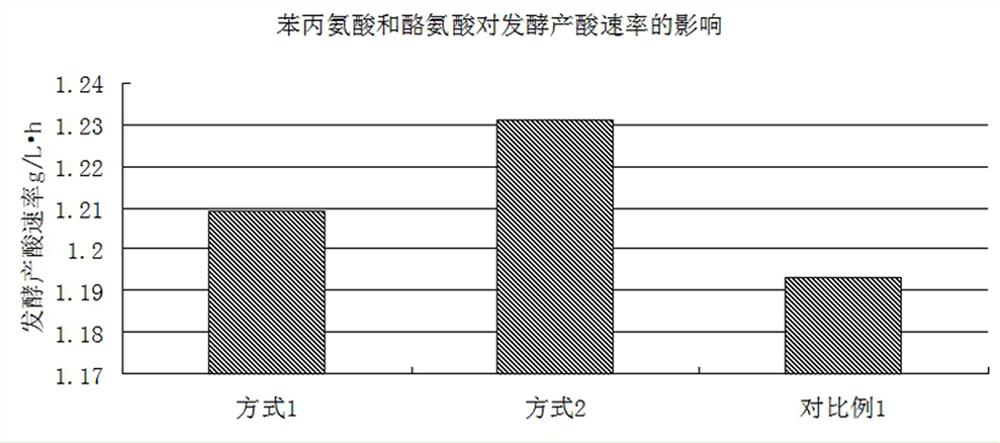

[0058] To verify the effects of phenylalanine and tyrosine on the yield of tryptophan and the rate of fermentation acid production, method 1: add 0.5g / L phenylalanine and 0.4g / L tyrosine to the fermentation medium; method 2 : Add 0.5g / L phenylalanine and 0.4g / L tyrosine to the nutrient solution; figure 1 As shown, mode 2 chooses to add phenylalanine and tyrosine to the nutrient solution, and the yield of tryptophan and the rate of fermentation acid production are higher than that of mode 1. The nutrient solution is added in the middle of fermentation. At this time, the aromatic amino acid The production of phenylalanine is in the process of rapid accumulation. By adding phenylalanine and tyrosine, there will be a feedback inhibition effect on the conversion of mycolic acid to prebenzoic acid, so that more mycolic acid flows to the anthranilic acid pathway, making The yield of tryptophan was increased; however, the way 1 was added to the fermentation medium, the accumulation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com