A kind of continuous preparation method of cellulose fiber

A technology of cellulose fibers and cellulose filaments, applied in the field of cellulose fibers, can solve the problems of restricting continuous and efficient preparation and promotion of cellulose fibers, unfavorable for subsequent development and application, and reducing fiber quality, and achieves stable preparation and optimization. Draftability, effect of reducing the degree of fibrillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

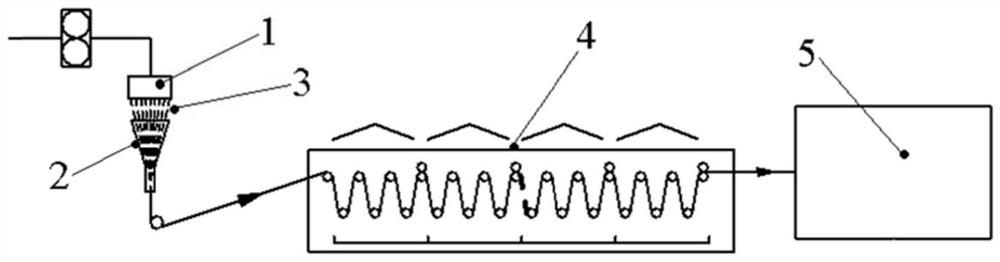

[0042] In this example, the following continuous preparation method is adopted to continuously spin cellulose fibers at a speed of 700 m / min by adjusting the tension of the tow at each stage of preparation:

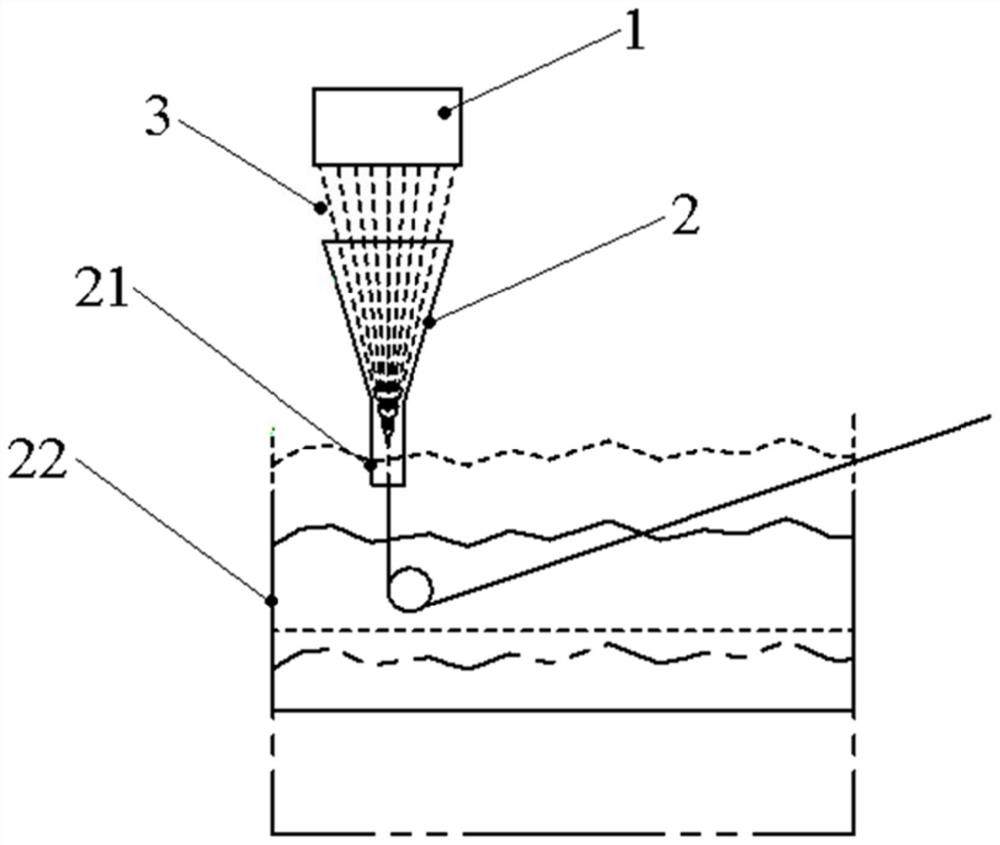

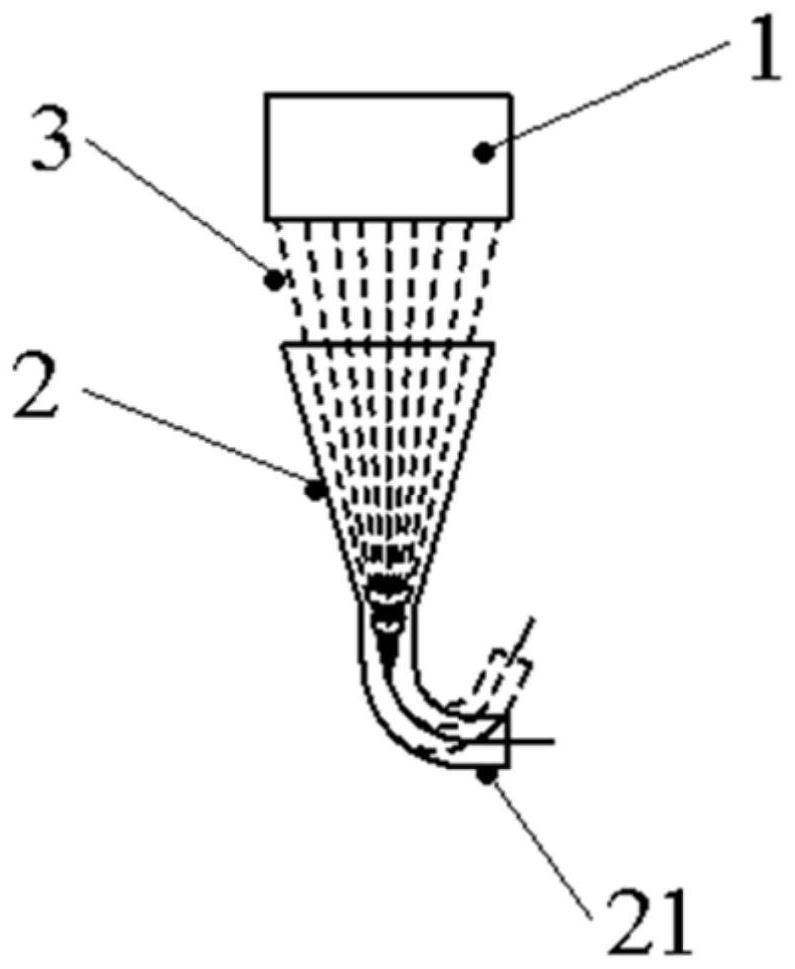

[0043] (1) The cellulose pulp and the NMMO aqueous solution are mixed, swollen, and dissolved to form a spinning stock solution with a cellulose content of 13%. The spinning temperature is 115°C, and the spinneret is extruded through a spinneret with a hole diameter of 0.08mm. , after being cooled by an air gap layer with a height of 80mm, a thin stream of stock solution is obtained, and the thin stream of stock solution is subjected to a forming tension of 0.75cN / dtex;

[0044] (2) The thin stream of stock solution of step (1) is entered into the high-speed coagulation system, and the speed of the coagulation bath is 600m / min, and the spray direction of the coagulation bath is consistent with the thin stream of stock solution (tow), so that the thin stream of stock soluti...

Embodiment 2

[0047] In this example, the following continuous preparation method is adopted to continuously spin cellulose fibers at a speed of 240 m / min by adjusting the tension of the tow at each stage of preparation:

[0048] (1) The cellulose pulp and the NMMO aqueous solution are mixed, swollen, and dissolved to form a spinning stock solution with a cellulose content of 9%. The spinning temperature is 95°C, and the spinneret is extruded through a spinneret with an aperture of 0.2mm. , after being cooled by an air gap layer with a height of 40mm, a thin stream of stock solution is obtained, and the thin stream of stock solution is subjected to a forming tension of 0.84cN / dtex;

[0049] (2) The stock solution trickle of step (1) is entered into the high-speed coagulation system, and the speed of the coagulation bath is 200m / min, and the coagulation bath injection direction is consistent with the stock solution trickle (tow), so that the stock solution trickle is drawn by the high-speed c...

Embodiment 3

[0052] In this example, the following continuous preparation method is adopted to continuously spin cellulose fibers at a speed of 450 m / min by adjusting the tension of the tow at each stage of preparation:

[0053] (1) The cellulose pulp and the NMMO aqueous solution are mixed, swollen, and dissolved to form a spinning stock solution with a cellulose content of 12%. The spinning temperature is 105°C, and the spinneret is extruded through a spinneret with an aperture of 0.3mm. , after being cooled by an air gap layer with a height of 60mm, a fine stream of stock solution is obtained, and the stock solution stream is subjected to a forming tension of 1.1cN / dtex;

[0054] (2) The thin stream of stock solution of step (1) is entered into the high-speed coagulation system, and the speed of the coagulation bath is 400m / min. Stretch down and solidify for molding, then the as-spun fibers are sent to the washing system, and the washed fibers are sent to the washing system and subjecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com