Quantitative detection reagent and detection method for sodium polydithiodipropane sulfonate in acid copper electroplating liquid

The technology of sodium polydithiodipropane sulfonate and detection reagent is applied in the field of analysis and detection of sodium polydithiodipropane sulfonate, which can solve the problems of cumbersome operation process, increased detection cost, corrosion and the like, and achieves good repeatability, Accurate, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

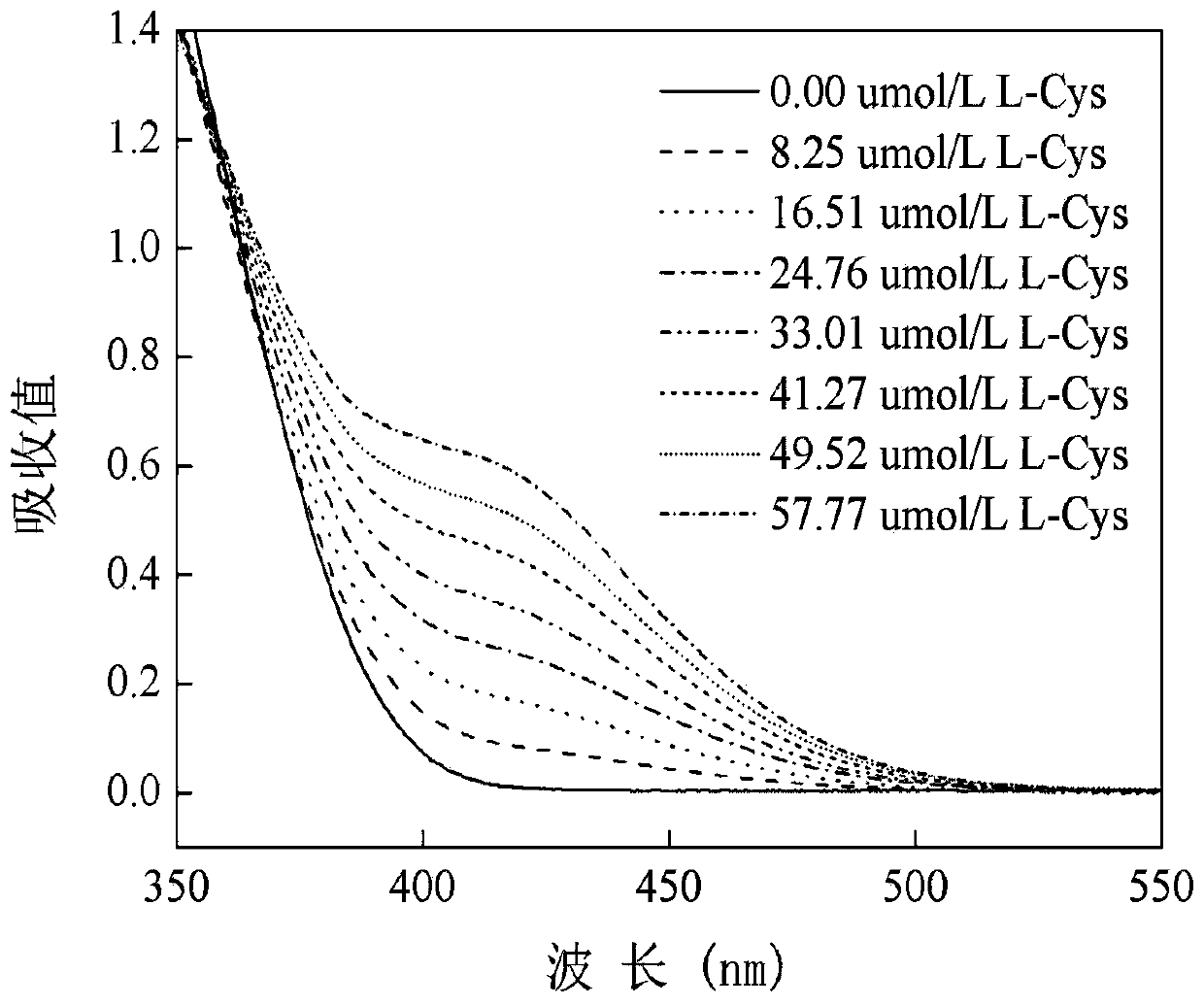

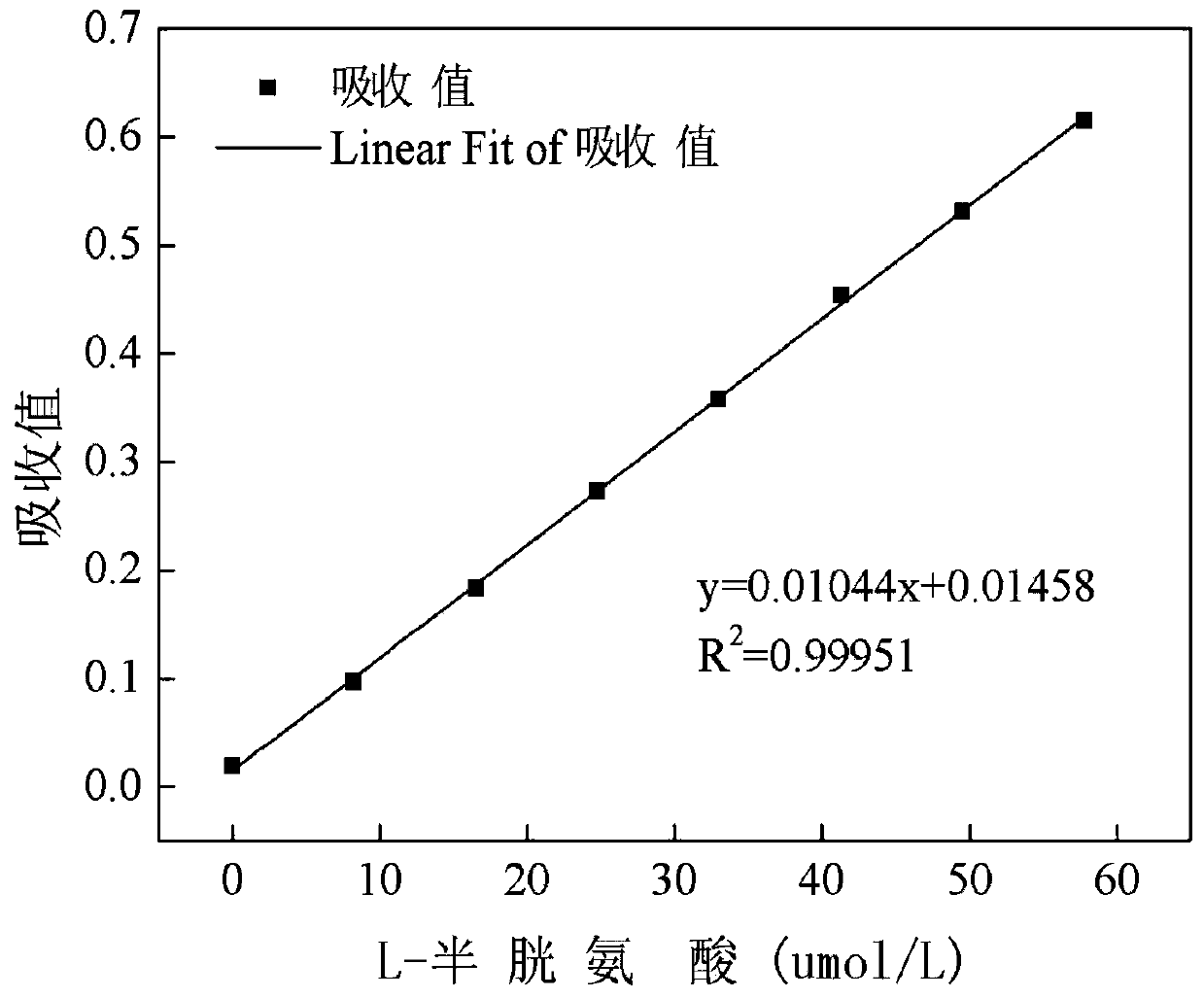

[0036] Step 1, drawing of L-cysteine standard curve:

[0037] (1) Accurately weigh 1.0g of L-cysteine and dissolve it in a 1000mL volumetric flask, and use H 2 PO 4 - -HPO 4 2- Dilute the buffer solution to the mark, and make 1.0g / L L-cysteine stock solution.

[0038] (2) Add the L-cysteine stock solution in 0mL, 1mL, 2mL, 3mL, 4mL, 5mL, 6mL, 7mL (1) to eight 100mL volumetric flasks respectively, and use H 2 PO 4 - -HPO 4 2- Dilute the buffer solution to the scale line, and make 8 kinds of L-cysteine standard solutions, the concentrations of L-cysteine are 0 μmol / L, 82.5 μmol / L, 165.1 μmol / L, 247.6 μmol / L , 330.1 μmol / L, 412.7 μmol / L, 495.2 μmol / L, 577.7 μmol / L.

[0039] (3) Use a pipette to pipette 1 mL of L-cysteine standard solution into a 10 mL colorimetric tube, add 100 μL of chromogenic reagent, dilute to the mark with deionized water, and develop color for 15 min.

[0040] (4) Take the concentration of the standard substance as the abscissa, and...

Embodiment 2

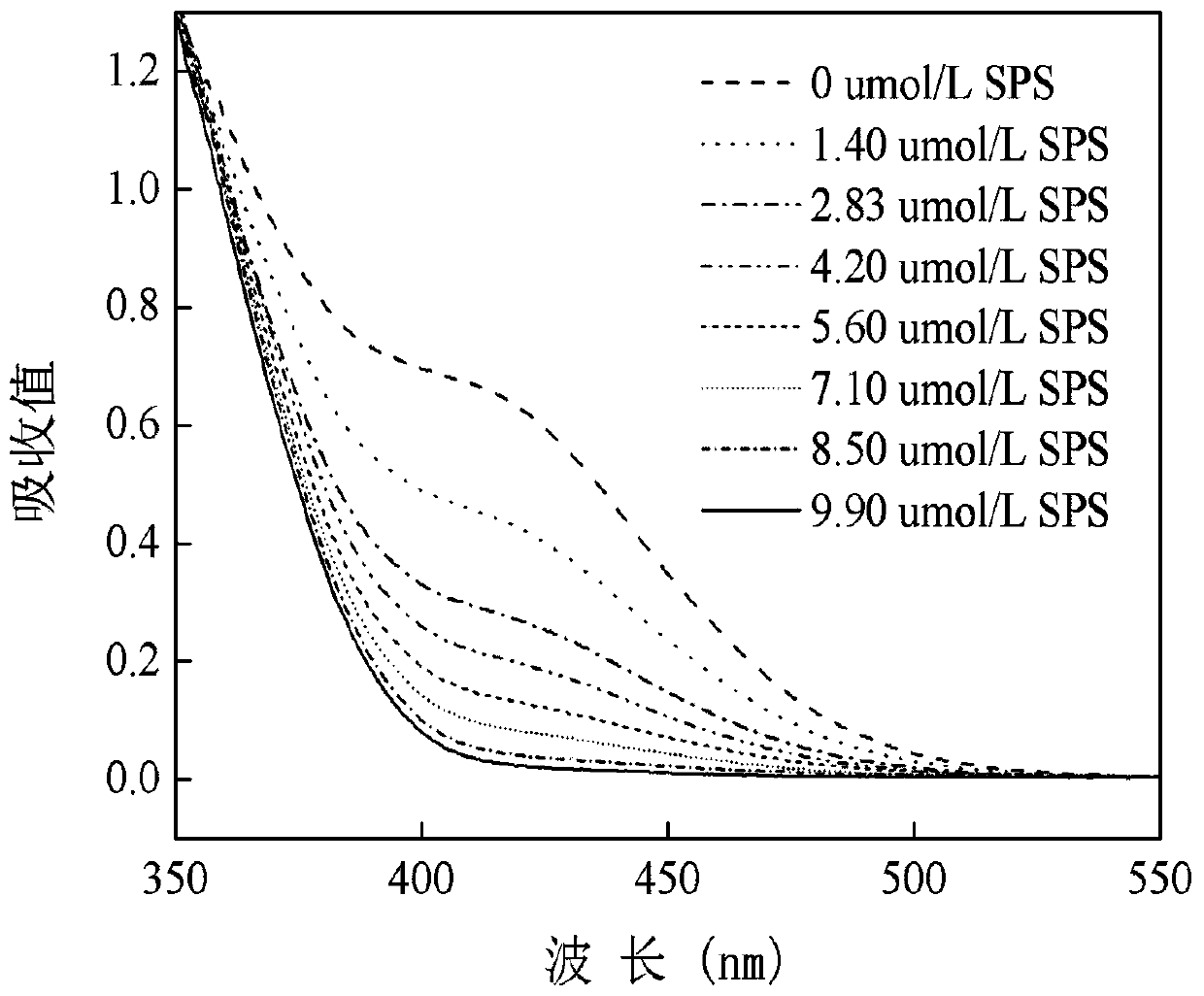

[0055] Embodiment two differs from embodiment one in that:

[0056] Pipette the sodium polydithiodipropanesulfonate electroplating solution to be tested in 1mL embodiment 1 step 2 (c), add 1000 μ L 80 μ mol / L mercaptoacetic acid, 5 mL buffer solution and 150 μ L chromogen, after it fully reacts, measure its The absorbance is calibrated with the L-cysteine standard curve to obtain the content of the total sulfhydryl group and substitute it into the sodium polydisulfide dipropane sulfonate-mercapto group relational formula to indirectly obtain the sodium polydisulfide dipropane sulfonate in the electroplating solution to be measured. content.

Embodiment 3

[0058] Embodiment three differs from embodiment two in that:

[0059] Pipette the sodium polydithiodipropanesulfonate electroplating solution to be tested in 1mL embodiment 1 step 2 (c), add 1500 μ L 80 μ mol / L mercaptoacetic acid, 5 mL buffer solution and 200 μ L chromogen, after it fully reacts, measure its The absorbance is calibrated with the L-cysteine standard curve to obtain the content of the total sulfhydryl group and substitute it into the sodium polydisulfide dipropane sulfonate-mercapto group relational formula to indirectly obtain the sodium polydisulfide dipropane sulfonate in the electroplating solution to be measured. content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com