Flexible solar concentrator with nano grains and preparation method of flexible solar concentrator

A solar concentrator and texture technology, applied in circuits, photovoltaic power generation, semiconductor devices, etc., can solve problems such as restricting the application environment and field, affecting light utilization efficiency, hard and fragile materials, etc., to improve photoelectric conversion efficiency, reduce The effect of light energy loss and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

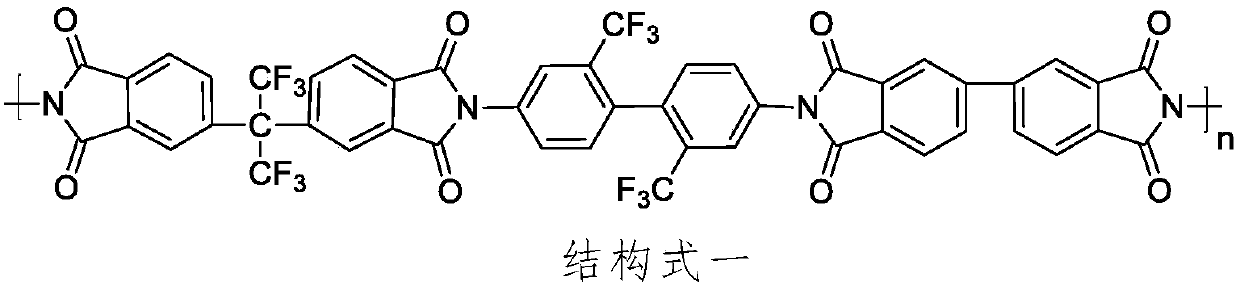

[0038]Dissolve 1 gram of cadmium selenide / cadmium sulfide (CdSe / CdS) quantum dots and 100 grams in 500 mL of dimethylacetamide (DMAC, light transmittance greater than 90%), with the following (structural formula 1) transparent poly The imides were mixed together and stirred for 1 hour to obtain a mixed slurry, which was left to stand to remove air bubbles, spread the slurry on a glass plate, covered with a DVD disc, and heated in an oven at 80°C for 4.5 hours. The product is taken out and cooled. The structural polyimide only needs to reflux the monomer in a common polar solution solvent, such as: N-methylpyrrolidone, and does not need ionic liquid auxiliary reaction, which is simple and low in cost. The light transmittance of the product is higher than 90%, and the glass transition temperature is higher than 311°C.

[0039]

Embodiment 2

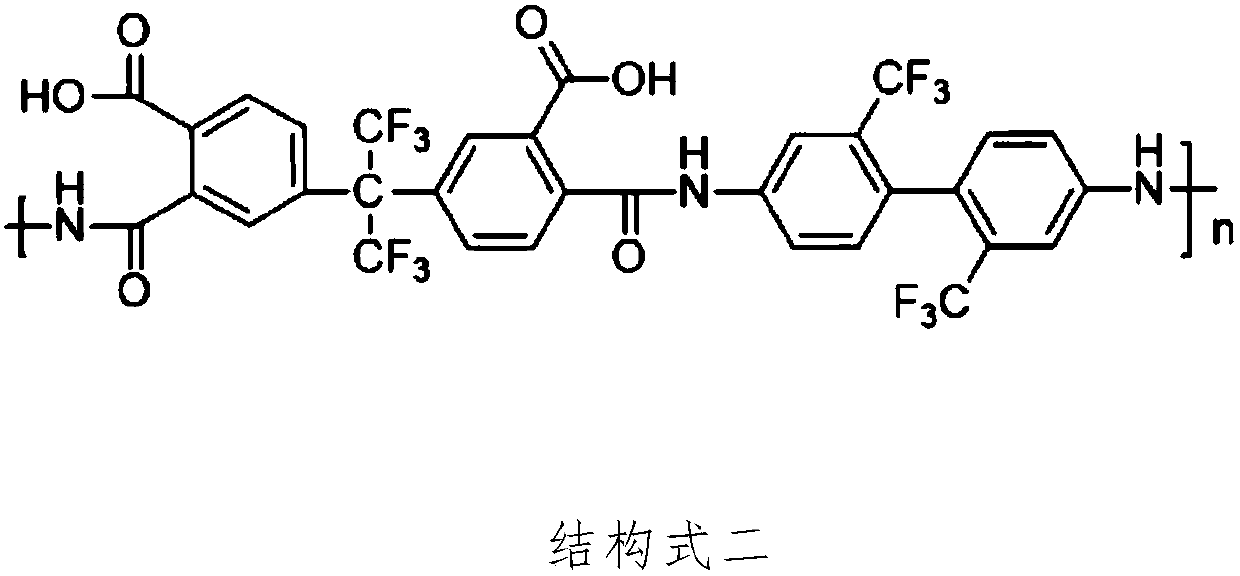

[0041] Dissolve 0.1 gram of cadmium selenide / cadmium sulfide (CdSe / CdS) quantum dots and 100 grams of transparent polyimide with the following (structural formula 2) in 500 mL of N,N-dimethylformamide (DMF) Mix together, stir for 1 hour to get a mixed slurry, let it stand, remove air bubbles, spread the slurry on a glass plate, cover the surface of the slurry with a DVD disc, and heat in an oven at 80°C for 4.5 hours. The product is taken out and cooled. The structural polyimide only needs to reflux the monomer in a common polar solution solvent, such as: N-methylpyrrolidone, and does not need ionic liquid auxiliary reaction, which is simple and low in cost. The light transmittance of the product is higher than 90%, and the glass transition temperature is higher than 265°C.

[0042]

Embodiment 3

[0044] 5 grams of cadmium selenide / cadmium sulfide (CdSe / CdS) quantum dots are mixed with 100 grams of transparent polyimide having the following (structural formula 1) dissolved in 500 mL of dimethylacetamide (DMAC), Stir for 1 hour to obtain a mixed slurry, let it stand still, remove air bubbles, spread the slurry on a glass plate, cover the surface of the slurry with a DVD disc, and heat in an oven at 80°C for 3 hours. The product is taken out and cooled. The structural polyimide only needs to reflux the monomer in an ordinary polar solution solvent, such as: N-methylpyrrolidone, and does not need ionic liquid auxiliary reaction, which is simple and low in cost. The light transmittance of the product is higher than 90%, and the glass transition temperature is higher than 318°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com