Carbon-coated silicon-based titanium-niobium composite material and preparation method thereof and lithium ion battery

A composite material and carbon coating technology, applied in the preparation/purification of carbon, niobium compounds, secondary batteries, etc., can solve problems such as poor stability, and achieve the effect of improving electrical contact, small volume effect, and high cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

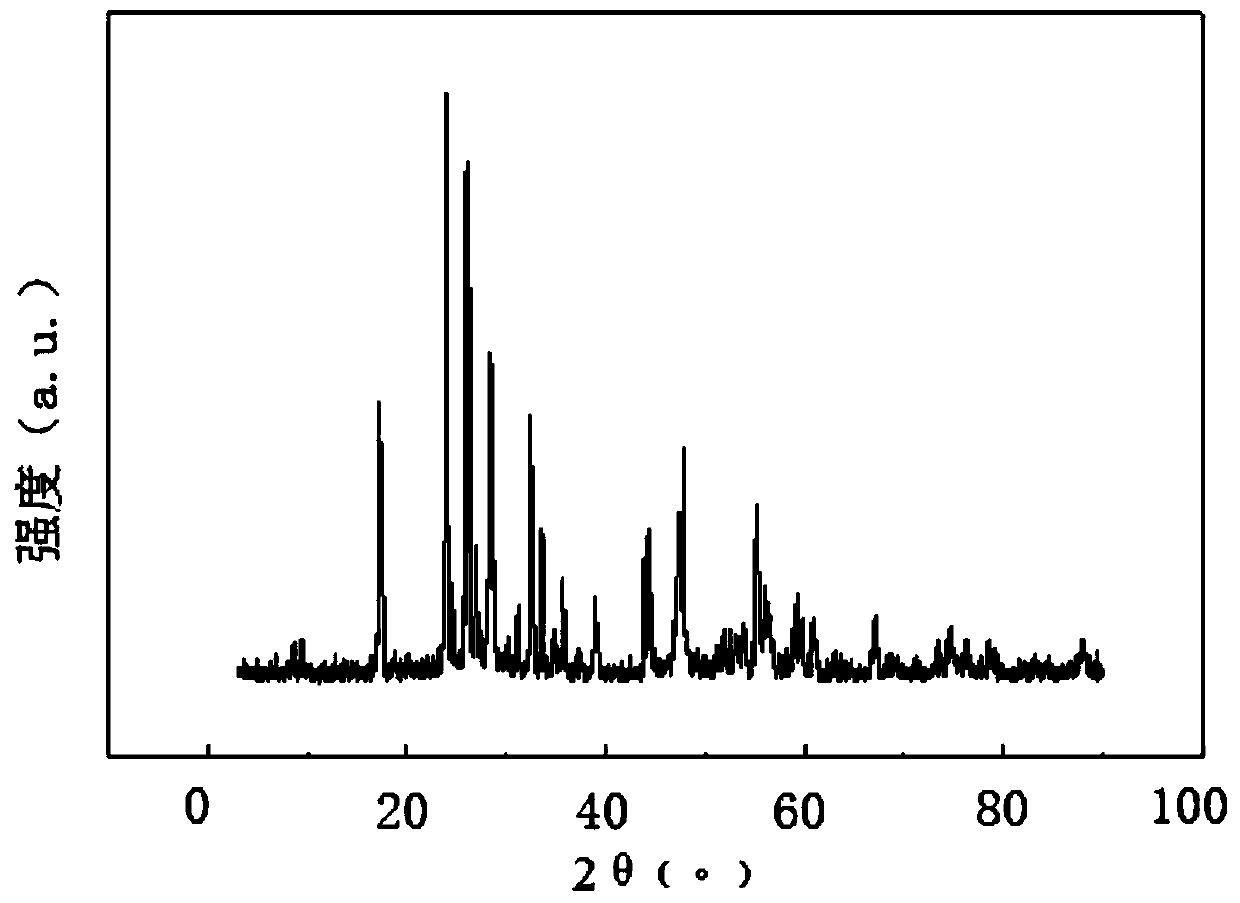

Image

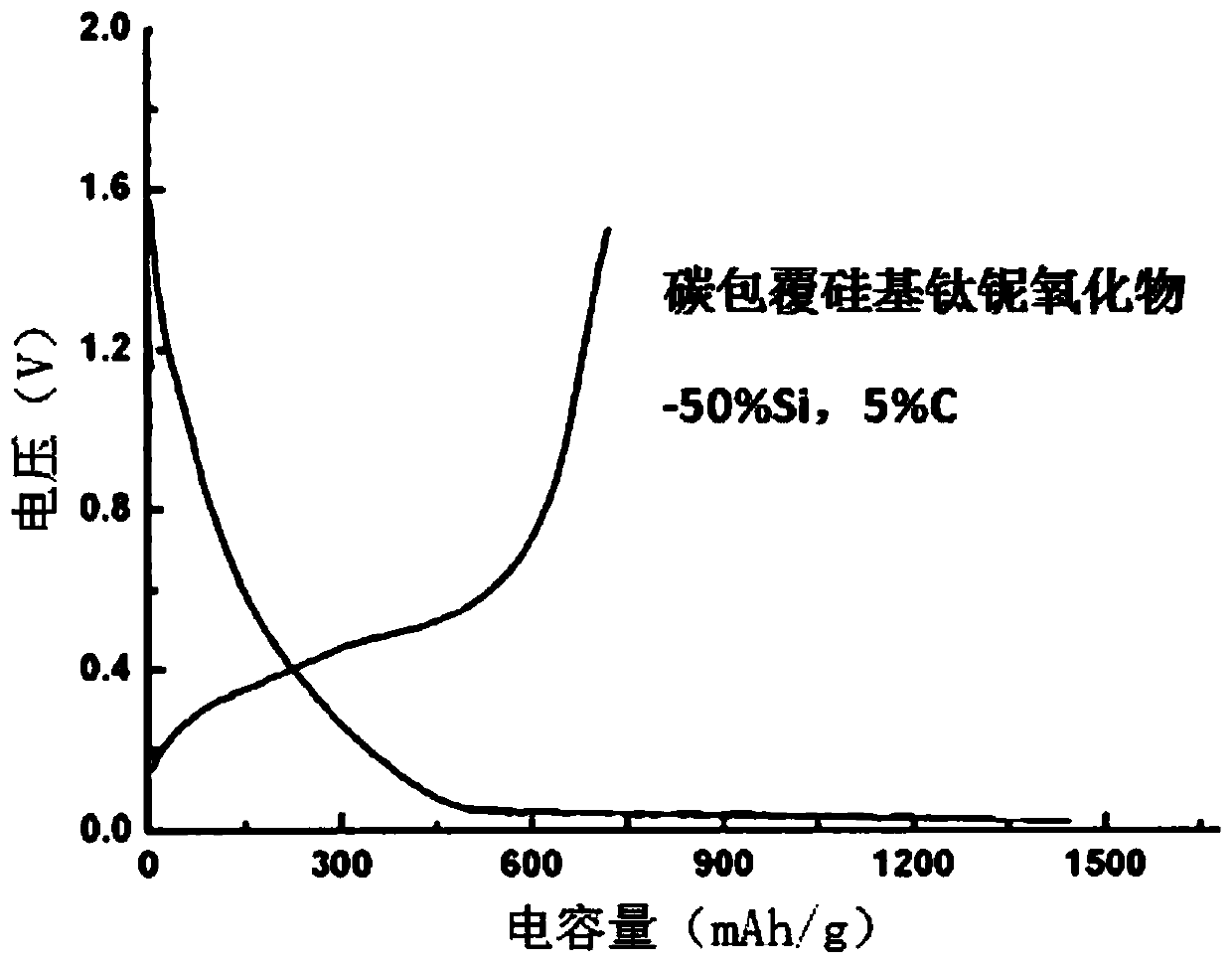

Examples

preparation example Construction

[0024] As described in the background art, the problem of poor stability of silicon materials in the charging and discharging process in existing lithium-ion batteries. In order to solve the above technical problems, the present application provides a method for preparing a carbon-coated silicon-based titanium-niobium composite material, the preparation method comprising: using titanium source and niobium source as raw materials to perform the first calcination process to obtain the first calcined product, The temperature of the first calcination process is 800-1200°C; the silicon source, the first calcination product and the carbon source are subjected to the second calcination process to obtain a carbon-coated silicon-based titanium-niobium composite material, and the temperature of the second calcination process is 500-1000 °C ℃; wherein, the titanium source is selected from one or more of anatase titanium dioxide, anatase titanium dioxide hydrate silicon powder and silicon ...

Embodiment 1

[0044] A method for preparing a carbon-coated silicon-based titanium-niobium composite material comprises:

[0045] Weigh deionized water, 400gNb 2 o 5 (1.50mol) and 139.57gTiO 2 2H 2 O (1.20mol) is mixed and prepared into a slurry with a solid content of 13%; the slurry is subjected to the first wet grinding to obtain the first slurry, wherein the grinding power is 10kwh / kg, and the particle size D50≤0.2μm; The first slurry is subjected to the first spray drying, the inlet temperature of the spray drying device used is 220°C, and the outlet temperature is 100°C.

[0046] The spray-dried material is subjected to a first calcination process in air, wherein the temperature of the first calcination process is 1100° C., and the sintering time is 6 hours. The product of the first calcining process is screened with a 200-mesh screen to obtain the first calcined product (titanium niobium oxide material).

[0047] Mix 400g of silicon powder with absolute ethanol to prepare a sili...

Embodiment 2

[0052] The difference from Example 1 is: the temperature of the first calcination process is 800°C, the temperature of the second calcination process is 1000°C, and the performance test method is the same as that of Example 1.

[0053] The charge and discharge rate is 0.1C, the first discharge gram capacity is 1030.2mAh / g, and the gram capacity after 50 cycles is 308mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com