Solar evaporator with hollow structure, and preparation method and application thereof

A solar evaporator and hollow technology, which is applied in the field of solar evaporator and its preparation, can solve the problems of difficult heat insulation materials, etc., and achieve the effect of stable product shape and structure, simple process, and favorable absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A hollow protruding melamine formaldehyde resin foam-based solar evaporator is prepared according to the following steps:

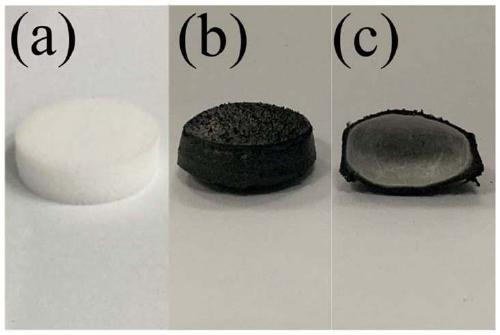

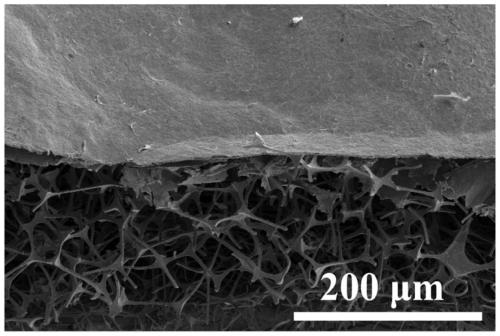

[0027] Take 45 mg of graphene powder and add it to 15 ml of deionized water, and ultrasonically treat it for 30 minutes to make it uniformly dispersed; add 140 mg of potassium hydroxide crystals to the above-mentioned graphene aqueous suspension, and mechanically stir for 5 minutes to prepare a uniform slurry; Take 15ml of slurry and melamine formaldehyde resin foam and place it in the lining of the hydrothermal reaction kettle, place the lining of the reaction kettle in the reaction kettle, and react at 180°C for 5 hours under airtight conditions; then take out the product after cooling down in the air environment, Obtain solar evaporator sample 1 after freeze-drying, its interior is hollow structure, exterior is two-layer structure and shell surface is protruding (referring to figure 1 and figure 2 ); the thickness of the polymer skeleton in th...

Embodiment 2

[0034] A hollow protruding melamine formaldehyde resin foam-based solar evaporator is prepared according to the following steps:

[0035] Get 45 mg of graphene powder and add it to 15 ml of deionized water, and ultrasonically treat it for 30 minutes to make it uniformly dispersed; add 102 mg of sodium hydroxide crystals to the above-mentioned graphene aqueous suspension, and mechanically stir for 5 minutes to prepare a uniform slurry; Take 15ml of slurry and polyurethane foam and put them in the lining of the hydrothermal reaction kettle, place the lining of the reaction kettle in the reaction kettle, and react at 180°C for 5 hours; take out the product after cooling down in the air environment, and obtain multi-layer after freeze-drying Structure of hollow convex solar evaporator sample 2.

[0036] The evaporation performance of the material is tested under the irradiation of simulated sunlight; sample 2 is exposed to a simulated sunlight (1KW m -2 ) can get 1.378kg m -2 h ...

Embodiment 3

[0038] A hollow protruding polyurethane foam-based solar evaporator is prepared according to the following steps:

[0039] Take 45 mg of graphene powder and add it to 15 ml of deionized water, and ultrasonically treat it for 30 minutes to make it uniformly dispersed; add 140 mg of potassium hydroxide crystals to the above-mentioned graphene aqueous suspension, and mechanically stir for 5 minutes to prepare a uniform slurry; Take 15ml of slurry and polyurethane foam and put them in the lining of the hydrothermal reaction kettle, place the lining of the reaction kettle in the reaction kettle, and react at 200°C for 3 hours; take out the product after cooling down in the air environment, and obtain multi-layer after freeze-drying Structure of hollow convex solar evaporator sample 3.

[0040] The evaporation performance of the material was tested under the irradiation of simulated sunlight; sample 3 was tested under the irradiation of simulated sunlight (1KW m -2 ) can get 1.280k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com