High-energy-storage silver niobate-based lead-free antiferroelectric ceramic and preparation method thereof

A silver niobate-based, antiferroelectric technology, applied in the field of high-energy storage silver niobate-based lead-free antiferroelectric ceramics and its preparation, can solve the problems of large doping amount, maximum polarization drop, material waste, etc. Achieve high energy storage efficiency, high energy storage efficiency, and high energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

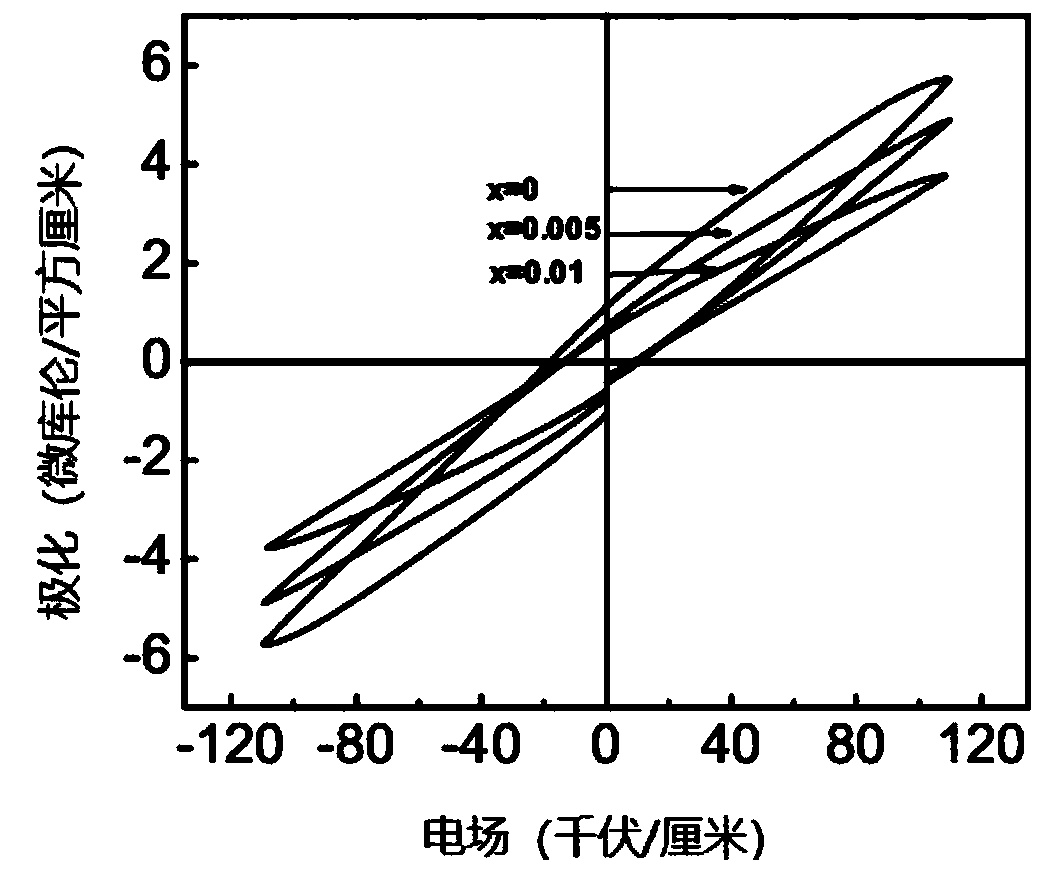

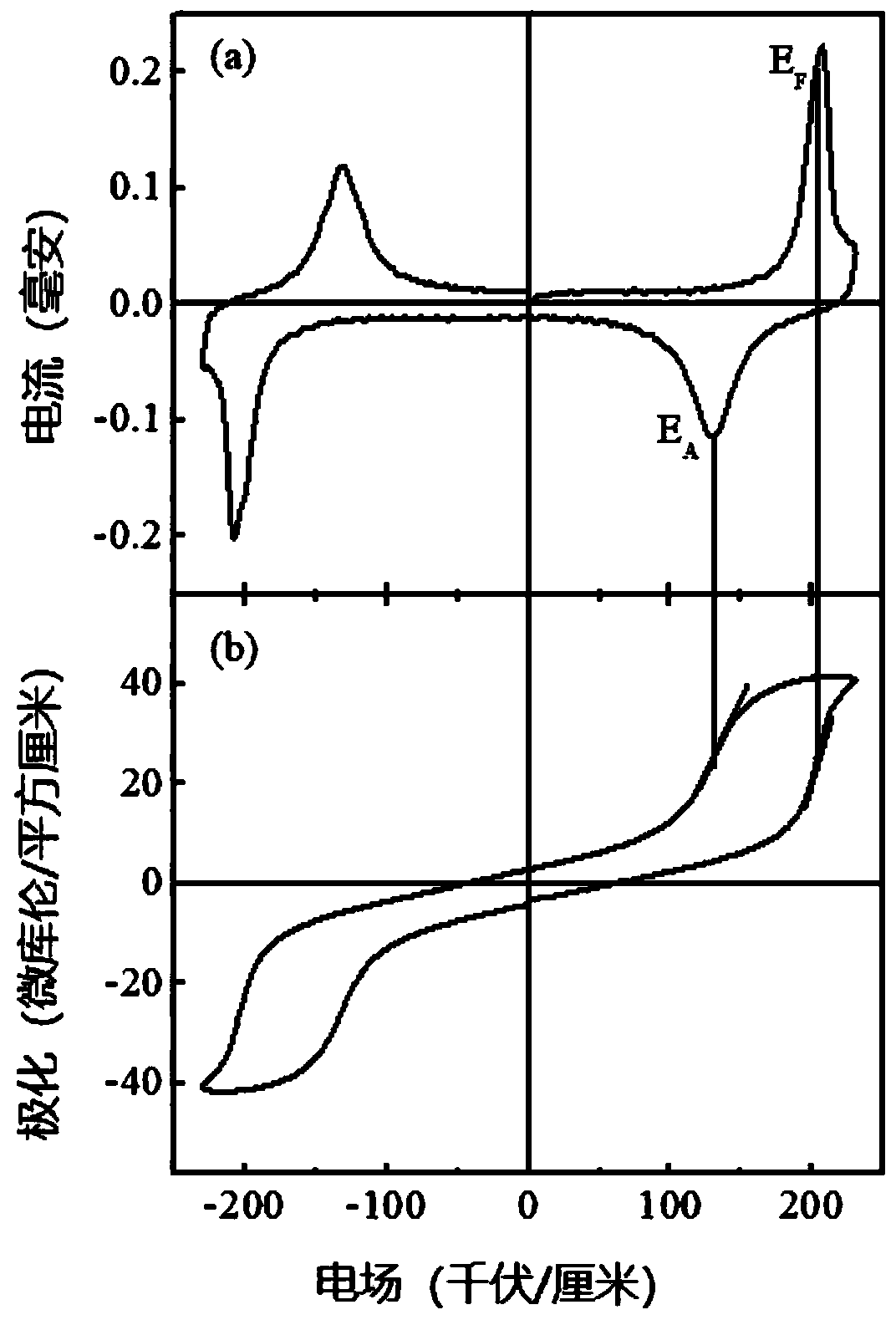

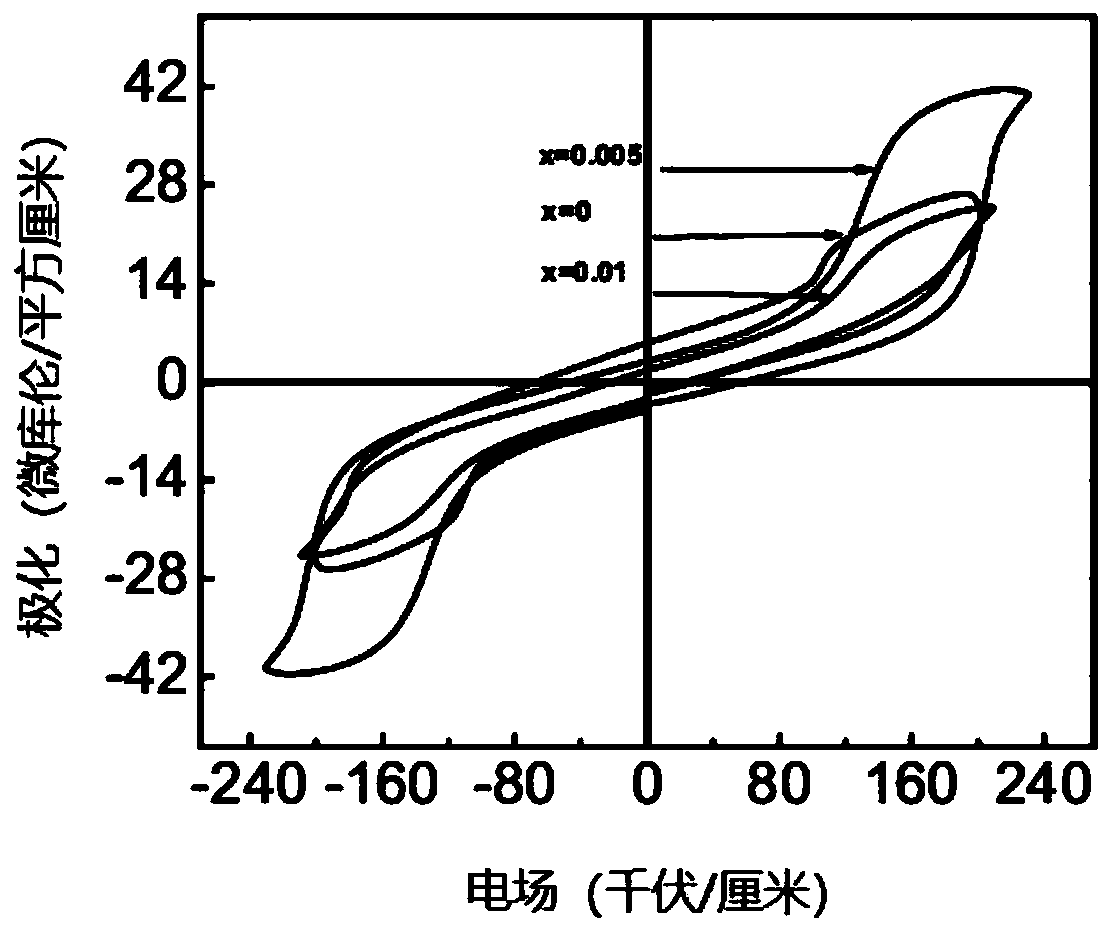

Embodiment 1

[0019] Preparation of Ag 0.985 La 0.005 Nb 0.9 Ta 0.1 o 3 Ceramics: weigh high-purity Ag 2 O powder 4.5802g, high purity Nb 2 o 5 Powder 4.7851g, high purity Ta 2 o 5 Powder 0.8839g, high purity La 2 o 3 The powder is 0.033g, and the weighed powder is poured into the agate ball milling jar, then absolute ethanol is added into the ball milling jar as the ball milling solvent, and the ball milling is mixed for 24 hours, and the ball milling speed is selected as 300 rpm. The ball-milled mixture is dried in an oven at 80°C for 12 hours; the dried powder is fully ground, passed through an 80-mesh sieve, and then pressed into an embryo body with a diameter of 20mm under a pressure of 50Mpa. Pre-fired under an oxygen atmosphere for 6 hours, and the heating and cooling rates were both 5°C / min; after the sintered porcelain was ground, it was ball-milled for the second time, dried, passed through a 120-mesh sieve, and then added with a mass fraction of 5% poly The vinyl alcoh...

Embodiment 2

[0021] Preparation of Ag 0.97 La 0.01 Nb 0.9 Ta 0.1 o 3 Ceramics: weigh high-purity Ag 2 O powder 5.4623g, high purity Nb 2 o 5 Powder 5.9867g, high purity Ta 2 o 5 Powder 1.1048g, high purity La 2 o 3 The powder is 0.1629g, and the weighed powder is poured into the agate ball milling jar, then absolute ethanol is added to the ball milling jar as the ball milling solvent, and the ball milling is mixed for 24 hours, and the ball milling speed is selected as 300 rpm. After the ball milling, the The ball-milled mixture is dried in an oven at 80°C for 12 hours; the dried powder is fully ground, passed through an 80-mesh sieve, and then pressed into an embryo body with a diameter of 20mm under a pressure of 50Mpa. Pre-fired under the atmosphere for 6 hours, and the heating and cooling rates were both 5°C / min; after the sintered ceramic pieces were ground, they were ball-milled for the second time, dried, and passed through a 120-mesh sieve, and then added polyethylene wit...

Embodiment 3

[0023] Preparation of Ag 0.94 La 0.02 Nb 0.9 Ta 0.1 o 3 Ceramics: weigh high-purity Ag 2 O powder 5.2879g, high purity Nb 2 o 5 Powder 5.9867g, high purity Ta 2 o 5 Powder 1.1048g, high purity La 2 o 3The powder is 0.2444g, pour the weighed powder into the agate ball mill jar, then add absolute ethanol to the ball mill jar as the ball mill solvent, mix the ball mill for 24 hours, and select the ball mill speed to be 300 rpm. The ball-milled mixture is dried in an oven at 80°C for 12 hours; the dried powder is fully ground, passed through an 80-mesh sieve, and then pressed into an embryo body with a diameter of 20mm under a pressure of 50Mpa. Pre-fired under the atmosphere for 6 hours, and the heating and cooling rates were both 5°C / min; after the sintered ceramic pieces were ground, they were ball-milled for the second time, dried, and passed through a 120-mesh sieve, and then added polyethylene with a mass fraction of 5%. The alcohol PVA aqueous solution is granula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com