Fermentation method for producing L-isoleucine

A fermentation method and isoleucine technology, which are applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve the problems of accumulation of heteroacids and increase in the level of heteroacids, and achieve inhibition of accumulation of heteroacids and reduction of impurities. Accumulation of acid, effect of reducing flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: A fermentation method for producing L-isoleucine. The cultured Corynebacterium glutamicum seed solution is inserted into a 50L fermenter with an inoculation amount of 15%, and the initial volume is 20L. The medium used for seeds consists of: glucose 20g / L, corn steep liquor 60g / L, potassium chloride 0.5g / L, magnesium sulfate 0.5g / L, defoamer 0.3mL / L, biotin 0.3mg / L, VB1 2mg / L, the rest is water. The medium composition used for fermentation is: glucose 80g / L, corn steep liquor 30g / L, ammonium sulfate 10g / L, dipotassium hydrogen phosphate 1g / L, magnesium sulfate 0.5g / L, defoamer 0.3mL / L, biotin 0.1 mg / L, VB1 0.1mg / L, the rest is water. The fermentation conditions are: tank pressure 0.05-0.1Mpa, ventilation rate 10-25L / min, stirring 200-800rpm, temperature 31-33°C, pH 6.8-7.2. Control the residual sugar concentration in the fermentation broth below 0.5g / L, and maintain the sugar consumption rate at 6g / L / h. The speed of L / h gradually reduces the sugar consump...

Embodiment 2

[0016] Embodiment 2: A kind of fermentation method of producing L-isoleucine, its difference with embodiment 1 is: sugar consumption rate is maintained at 7g / L / h, when miscellaneous acid (comprising alanine, lysine etc.) when the content reaches 1g / L, gradually reduce the sugar consumption rate until the tank is put at a speed of 0.4g / L / h, and all the other are identical to Example 1.

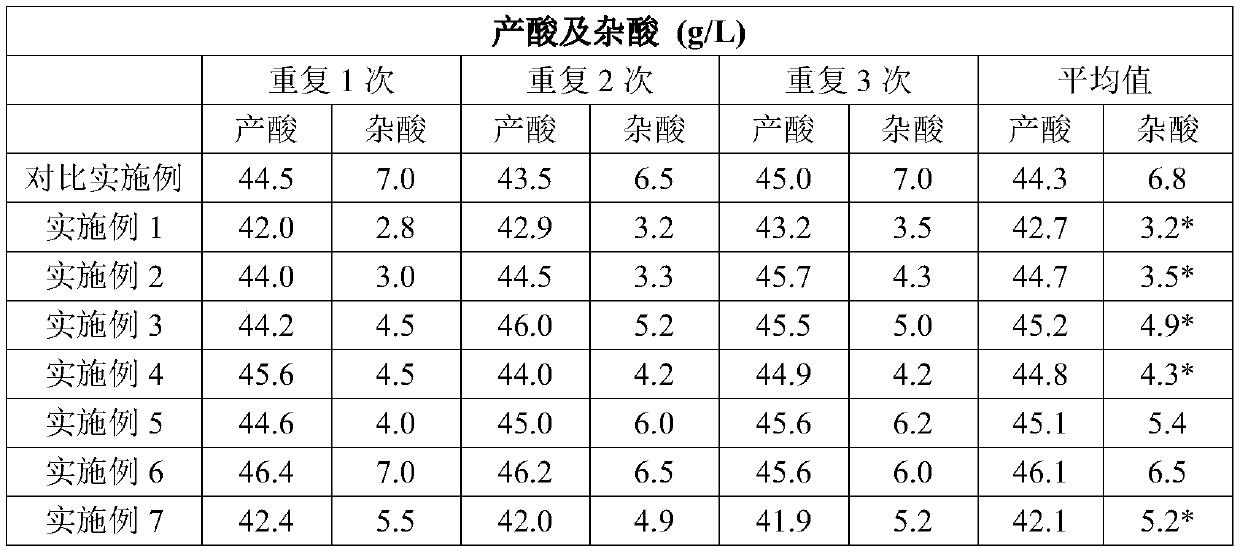

[0017] This example was repeated 3 times. After the fermentation was completed, the content of L-isoleucine and the content of heteroacids in the fermentation broth were measured by HPLC. The fermentation indicators are shown in Table 1 below.

Embodiment 3

[0018] Embodiment 3: A kind of fermentation method of producing L-isoleucine, its difference with embodiment 1 is: sugar consumption rate is maintained at 7g / L / h, when miscellaneous acid (comprising alanine, lysine etc.) content reaches 2g / L, gradually reduces sugar consumption rate with the speed of 0.4g / L / h until putting tank, and all the other are identical with embodiment 1.

[0019] This example was repeated 3 times. After the fermentation was completed, the content of L-isoleucine and the content of heteroacids in the fermentation broth were measured by HPLC. The fermentation indicators are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com