A kind of supported-coated noble metal catalyst and its preparation and application

A precious metal catalyst, precious metal technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, catalyst protection, etc., can solve the problem of sintering and deactivation of active centers, and promote the movement and sintering of metal particles. and other problems, to achieve the effect of low cost, high repeatability and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

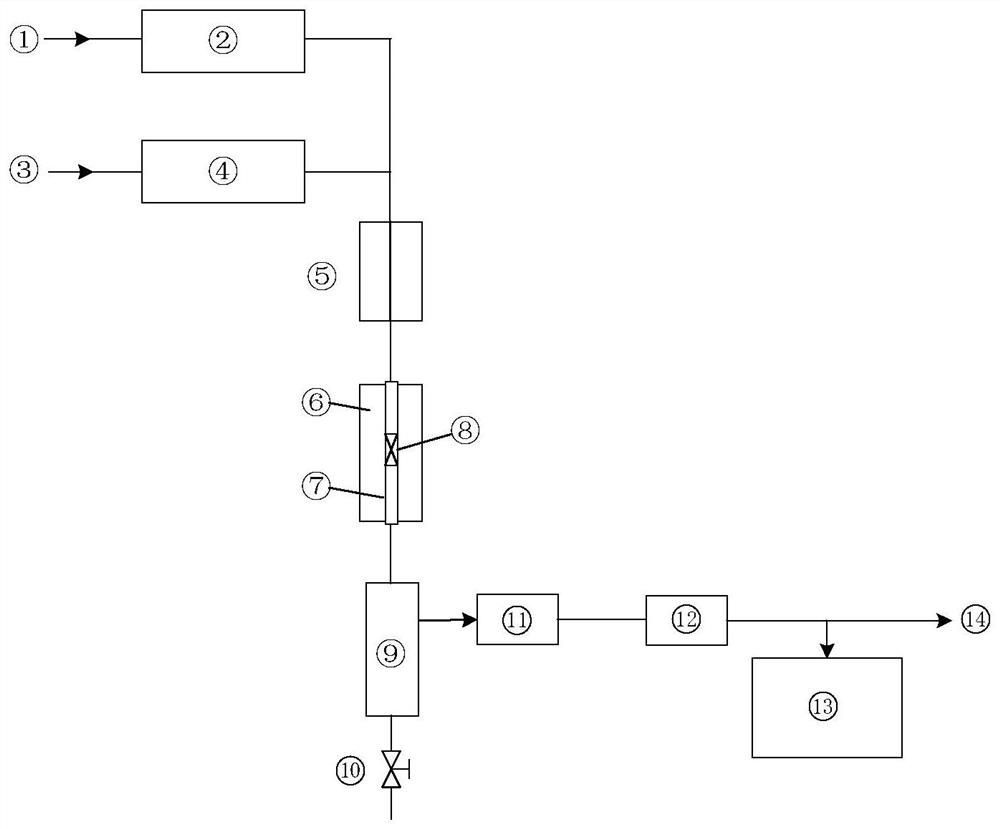

Image

Examples

preparation example Construction

[0027] Preparation of alumina carrier raw materials:

[0028] Put 40g of commercial pseudo-boehmite into a muffle furnace, heat up to 600°C in an air atmosphere at a heating rate of 1°C / min, roast for 5 hours, and cool down to room temperature naturally to obtain 31g of γ-alumina. is alumina I;

[0029] Put 30g of commercial pseudo-boehmite into a muffle furnace, heat up to 1200°C in an air atmosphere at a heating rate of 2°C / min, roast for 12 hours, and cool down to room temperature naturally to obtain 23g of α-alumina. is alumina II;

[0030] Put 10g of commercial pseudo-boehmite into an atmosphere roasting furnace, pass through a nitrogen-diluted ammonia atmosphere, the atmosphere contains 80mol% nitrogen and 20mol% ammonia, and heat it to 700°C at a heating rate of 2°C / min. Keep it for 5 hours, switch the atmosphere to nitrogen, cool down to normal temperature naturally, and obtain 7.8g of alumina containing γ phase and η phase, wherein γ-alumina accounts for 15%, and η-...

Embodiment 1

[0032] Catalyst preparation:

[0033] Weigh 8.18g of alumina I, 1.0g of alumina II and 0.82g of alumina III, grind them manually in a mortar for 30min, and mix them uniformly to obtain 10g of alumina carrier powder. The main component of alumina carrier is γ- Alumina, also comprising 7 wt% η-alumina and 10 wt% α-alumina. These alumina carrier powders were mixed with 50 mL of ruthenium trichloride solution with a concentration of 0.04 mol / L in an open beaker. The solid-liquid mixture was mechanically stirred at a stirring speed of 200 rpm, the mixture was heated to 60°C and kept for 2 hours, the resulting mixture was transferred to an oven, and kept at 105°C for 10 hours, and then the obtained solid powder was transferred to the atmosphere In the roasting furnace, in a nitrogen atmosphere, the temperature was raised to 550°C at a rate of 10°C / min, and kept for 4 hours to obtain alumina powder 2% Ru / Al loaded with ruthenium particles 2 o 3 ;

[0034] 10g of 2%Ru / Al 2 o 3 M...

Embodiment 2

[0036] Catalyst preparation:

[0037] Weigh 7.6g of alumina I and 2.4g of alumina II, grind them manually in a mortar for 30min, and mix them uniformly to obtain 10g of alumina carrier powder. The main component of alumina carrier is γ-alumina, which also contains 24wt % of alpha-alumina. These alumina carrier powders were mixed with 50 mL of rhodium trichloride solution with a concentration of 0.03 mol / L in an open beaker. Mechanically stir the solid-liquid mixture at a stirring speed of 240rpm, heat the mixture to 65°C and keep it for 2 hours, transfer the resulting mixture to an oven, keep it at 105°C for 10 hours, and then transfer the obtained solid powder to the atmosphere In the roasting furnace, in a nitrogen atmosphere, the temperature was raised to 550°C at a rate of 10°C / min, and kept for 4 hours to obtain alumina powder 1.5%Rh / Al loaded with rhodium particles 2 o 3 ;

[0038] 10g of 1.5%Rh / Al 2 o 3 Mix the powder with 260mL of ethanol, and keep stirring the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com