Preparation method and application of biomass-based electrode material

A base electrode and biomass technology, applied in chemical instruments and methods, hybrid capacitor electrodes, carbon compounds, etc., can solve the problems of poor electrochemical performance, achieve reasonable pore size distribution, high specific surface area, and increase specific capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of a biomass-based electrode material of the present invention is specifically implemented according to the following steps:

[0029] Step 1. Grinding the dried locust and potassium hydroxide respectively, sieving, and mixing evenly to obtain a mixed sample;

[0030] When sieving, use a 200-300-mesh sieve;

[0031] The mass ratio of dry locusts to potassium hydroxide is 1:1-9;

[0032] Step 2. Transfer the mixed sample in step 1 to the corundum boat, then put the corundum boat into the tube furnace, feed nitrogen at a rate of 40-60mL / min, and raise the temperature at a rate of 2-10°C / min Heat to 220°C, hold for 1-3 hours, then raise the temperature to 800-1200°C at a rate of 5-10°C / min, hold for 0.5-2h, cool naturally to room temperature, and obtain carbon materials;

[0033] Step 3, using a pulverizer to pulverize the carbon material obtained in step 2, sieving, adding dilute hydrochloric acid, and stirring mechanically for 5 to 10 minutes to obt...

Embodiment 1

[0043] The preparation process of the electrode material in this embodiment is as follows: Weigh 1 part of locust and 1 part of potassium hydroxide, use a pulverizer to grind them to below 200 mesh, and then mix them uniformly to obtain a mixed sample; transfer the mixed sample to a corundum boat, and then Put the corundum boat into the tube furnace, feed nitrogen, and the nitrogen flow rate is 40mL / min; set the temperature rise program, the temperature rise rate is 2°C / min, when the temperature rises to 220°C, keep it for 60min, and then raise the temperature to 5 / min 1000°C, keep warm for 30 minutes, and finally cool down naturally to obtain activated carbon materials. After cooling, the corundum boat was taken out, the carbon material was ground and passed through a 100-mesh sieve, and then washed successively with dilute hydrochloric acid and deionized water with a pH equal to 2. Vacuum drying is carried out after washing product suction filtration, and drying temperature ...

Embodiment 2

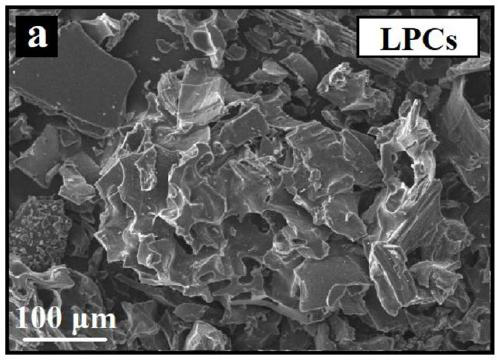

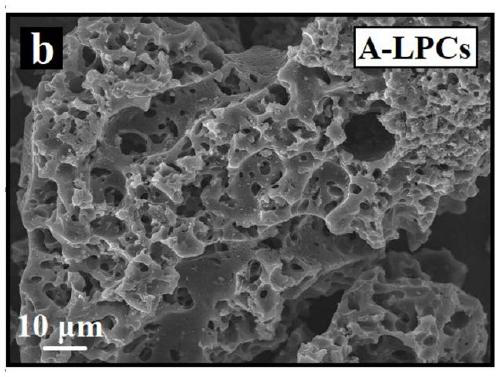

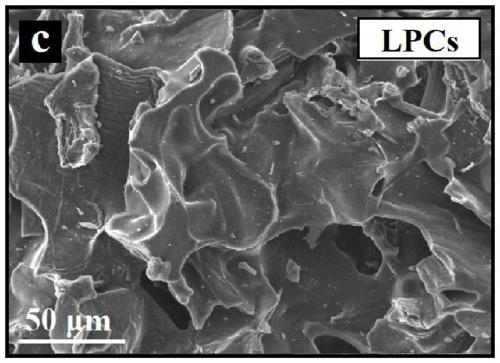

[0045] The difference between this example and Example 1 is that the mass fraction of raw materials is: 1 mass fraction of locusts, no potassium hydroxide is added, and the rest of the step parameters and process conditions are the same as in Example 1. The electrode prepared in this example The materials are denoted as LPCs, and SEM is carried out on many electrode materials ( figure 1 , image 3 ) and nitrogen adsorption and desorption ( Figure 5-6 ) experiment, as the control group of embodiment 1.

[0046] From figure 1 , image 3 It can be seen that the surface of the LPCs electrode material presents a sheet-like structure, but there are no pores on the surface, while the A-LPCs electrode material added with potassium hydroxide ( figure 2 , Figure 4) surface shows pores of different sizes, and the pore wall is thinner, which is conducive to improving the electronic conductivity of the electrode material and improving the electricity storage performance of its supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com