Method for extracting high-quality krill oil from krill

A krill oil, high-quality technology, applied in the production of fat oil/fat, refining of fat oil/fat, and fat production, can solve the problems of easy adsorption of phospholipids, loss of effective components, etc., to achieve simple operation of the preparation process and improved storage stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

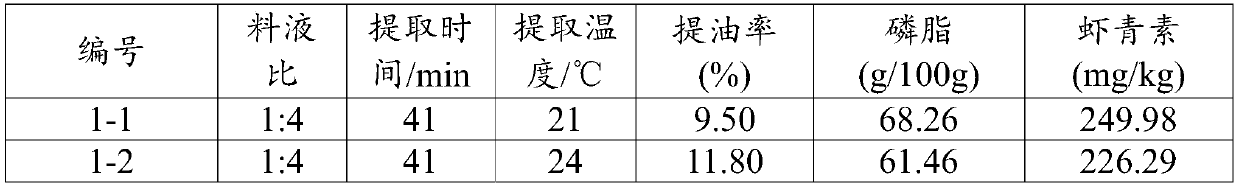

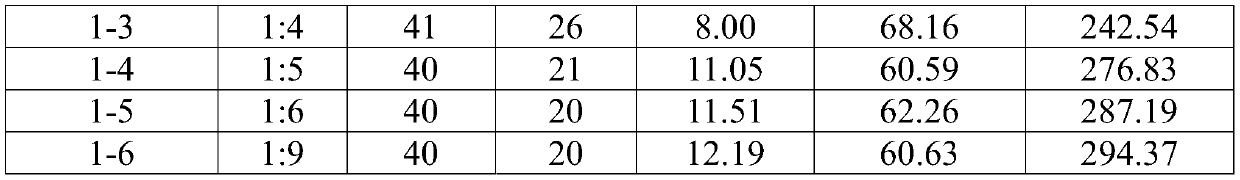

[0041] Example 1, krill oil extraction process and optimization when no alkali is added

[0042] The method for preparing krill oil from Antarctic krill powder comprises the steps:

[0043] S1, the Antarctic krill meal is subjected to countercurrent extraction with an organic solvent (ethanol) to obtain an extract;

[0044] S2. Distilling the extract obtained in step S1 under reduced pressure to obtain a concentrated solution;

[0045] S3, adding purified water to the concentrated solution in step S2 for refining, fully mixing and then standing to separate layers, collecting the crude oil in the lower layer;

[0046] S4. Mix the crude oil in the lower layer of step S3 with absolute ethanol, let it stand, filter, and retain the solution;

[0047] S5. The solution in step S4 is heated and desolvated by vacuum distillation to obtain purified and refined krill oil.

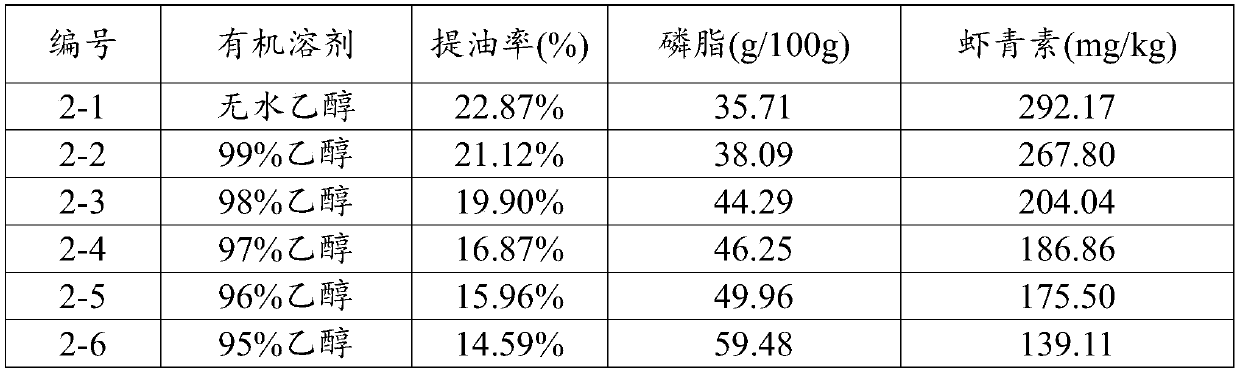

[0048] In step S1, the water content and ethanol concentration in the krill powder will affect the quality, extr...

Embodiment 2

[0072] Embodiment 2, alkali deacidification and process optimization

[0073] Using Antarctic krill powder as raw material, extract according to the method of Example 1, the difference is: the water is replaced with alkaline water, the Antarctic krill extract is concentrated to a solid content of 10% to 20%, and the concentrated solution is added Alkaline water (calculated as water) with a mass of 0.5-0.9 times, stirred for 1 hour, the stirring temperature was 25°C-60°C, and the stirring rate was 400-1000rpm / min; In absolute ethanol, filter; the filtrate is vacuum precipitated to obtain refined Antarctic krill oil.

[0074] The preparation of the alkaline water: sodium carbonate (soda ash) or sodium hydroxide (caustic soda) is dissolved in deionized water for preparation; the actual amount of caustic soda added is 0.9 to 1.2 times the theoretical amount of caustic soda added, and the actual amount of soda ash added is the theoretical amount of caustic soda added 0.5 to 1.5 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com