Low-temperature expandable graphite for sealing channeling by steam injection in heavy oil reservoirs and its preparation method and application

A technology for expanded graphite and heavy oil reservoirs, applied in chemical instruments and methods, earthwork drilling, sealing/sealing, etc. Low construction cost, simple preparation method and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

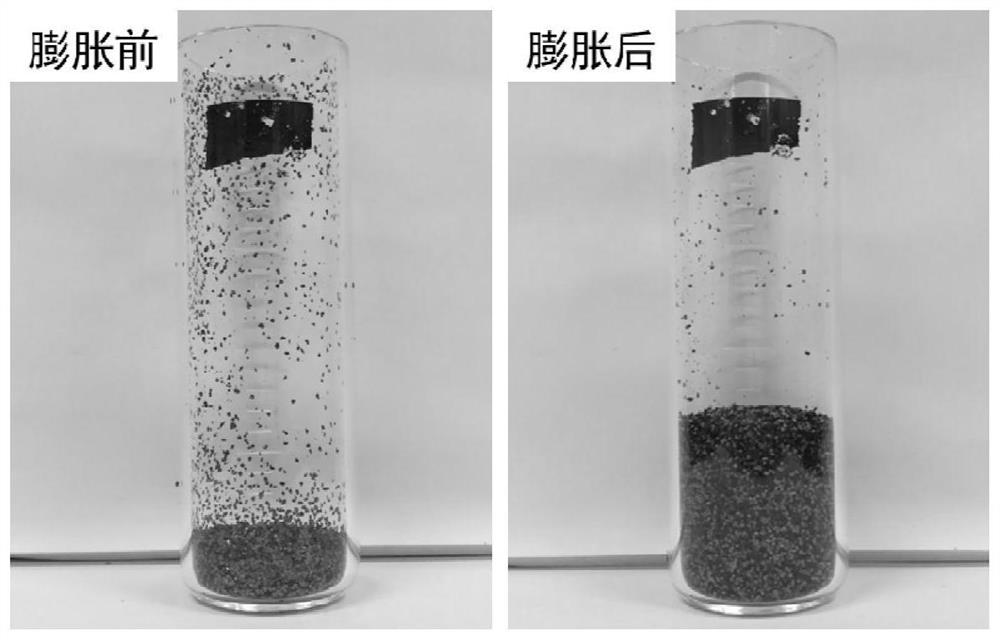

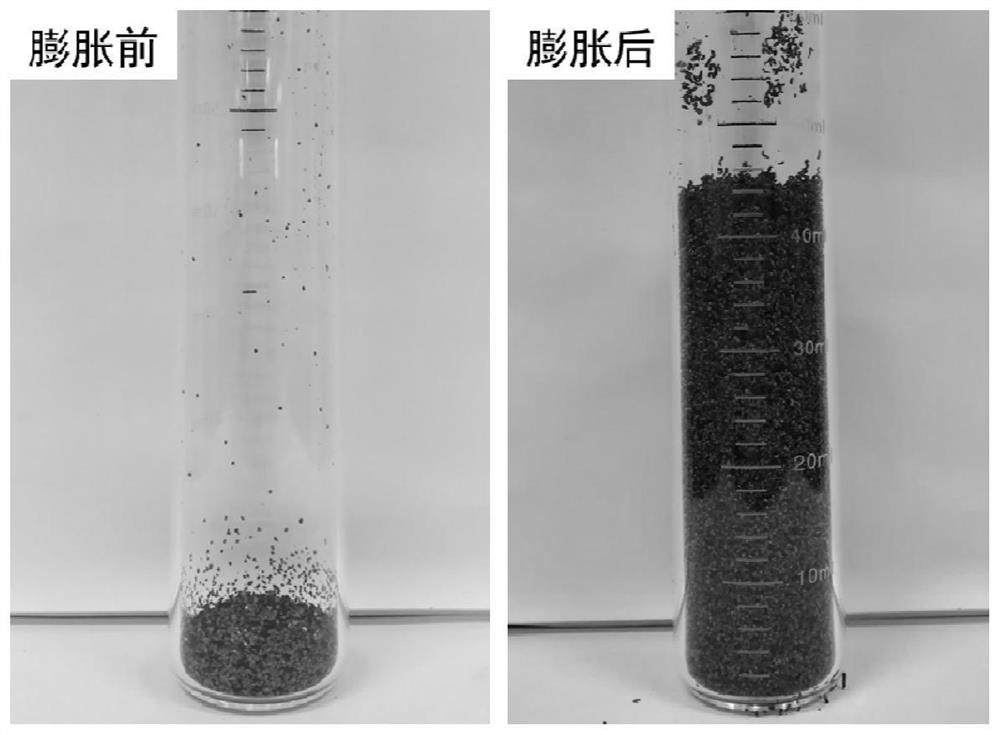

[0025] One aspect of the present invention provides a method for preparing low-temperature expandable graphite suitable for steam injection sealing channeling in heavy oil reservoirs, the method comprising: in an aqueous solvent, the compound represented by formula (1), oxidant, acid, Contact reaction between metal salt and graphite;

[0026] Formula 1)

[0027] L is a link or a C1-C4 alkylene group; M is hydrogen or a metal ion.

[0028] According to the present invention, by using the compound represented by formula (1) of the present invention, oxidizing agent, acid and alkali metal salt to treat graphite, graphite can be fully intercalated to obtain a highly expandable graphite system at a lower temperature, It should be understood that the compounds represented by formula (1), oxidants, acids and alkali metal salts in the present invention are intercalants for graphite.

[0029] According to the present invention, in order to make intercalants have a better coordinati...

Embodiment 1

[0060] This example is used to illustrate the low-temperature expandable graphite of the present invention and its preparation method.

[0061] (1) An aqueous solution containing sulfamic acid and potassium permanganate (the content of sulfamic acid is 5g, the content of potassium permanganate is 1g, and the amount of water is 30g) and 10g flake graphite (purchased from Qingdao Hengrunda Graphite Products Co., Ltd.’s 60-mesh flake graphite) was stirred and mixed for 5 minutes, then placed at 40° C. for ultrasonic reaction for 30 minutes, then taken out, and the reaction waste liquid was separated by suction filtration, and the remainder was graphite after the first contact reaction;

[0062] (2) the perchloric acid dispersion liquid containing sodium nitrate (sodium nitrate content is 4g; What perchloric acid adopts is that concentration is the concentrated perchloric acid of 72% by weight, and its consumption is 30g) with the graphite after the first contact reaction Stir and...

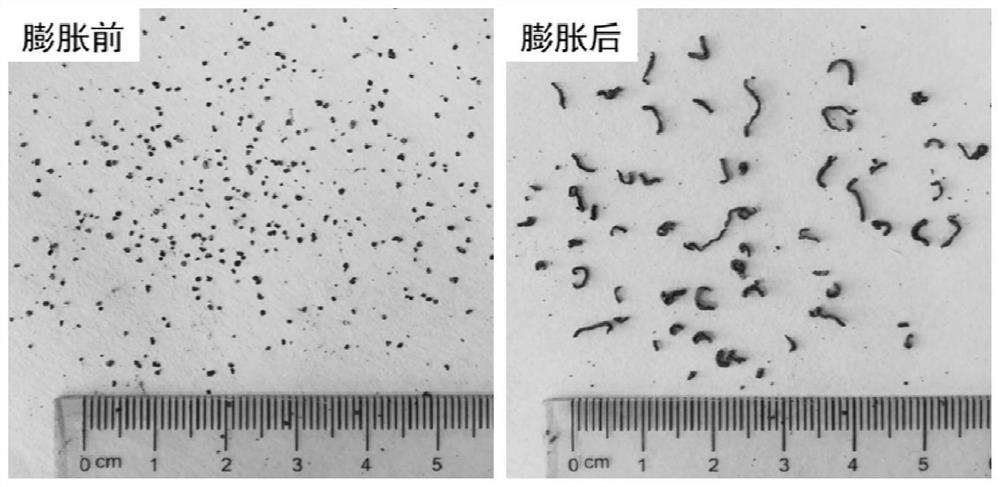

Embodiment 2

[0065] This example is used to illustrate the low-temperature expandable graphite of the present invention and its preparation method.

[0066] According to the method described in Example 1, the difference is that in step (1), in the aqueous solution containing sulfamic acid and potassium permanganate, the content of sulfamic acid is 8g, and the content of potassium permanganate is 2g, water The consumption is 25g; The finally obtained particle diameter is the expandable graphite G2 of 60.1 μ m; Wherein, step (3) process has also measured the variation curve of graphite particle diameter with shearing time under 20Hz colloid mill shearing condition, as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com