Preparation method of transparent conductive small ball, transparent conductive small ball and application

A technology of transparent conductive and small balls, which is applied in the field of electronics, can solve the problems of limited optical transparency of conductive small balls, cumbersome preparation process of conductive small balls, unfavorable development of optoelectronic devices, etc., and achieves short preparation process, excellent mechanical properties, The effect of green environmental protection in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0043] A kind of transparent conductive bead, and its preparation process is as follows:

[0044] S1: Preparation of polymerizable deep eutectic solvent: Mix hydrogen bond acceptor choline chloride and hydrogen bond donor acrylic acid at a molar ratio of 1:2, heat and stir at 90°C for about 3 hours to form a uniform, colorless polymerizable polymeric deep eutectic solvent;

[0045] S2: Preparation of mixed solution: Add photoinitiator (1173 mixed with TPO at a mass ratio of 1:1) and cross-linking agent polyethylene glycol diacrylate to a polymerizable deep eutectic solvent to obtain a mixed solution. The mass fractions of photoinitiator and crosslinking agent relative to polymerizable deep eutectic solvent are shown in Table 1 respectively;

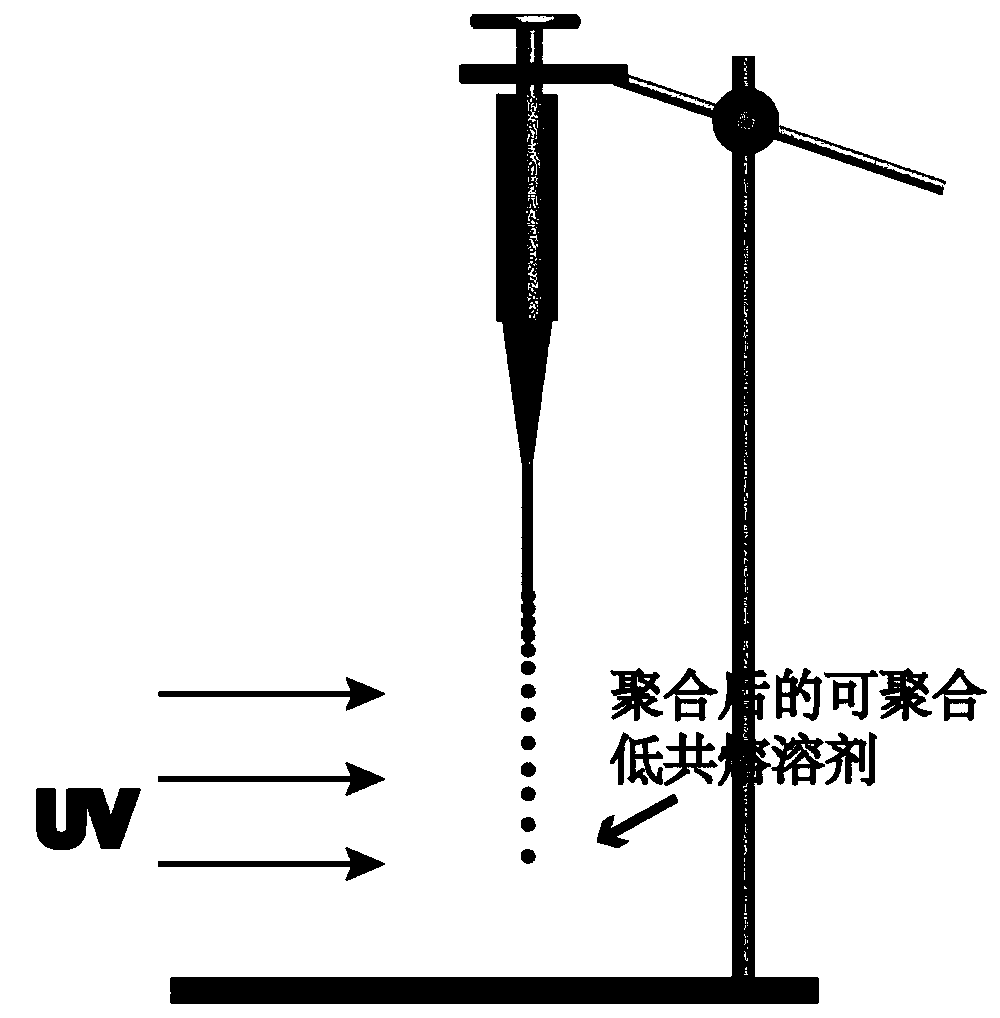

[0046] S3: Injection preparation: Inhale the mixed solution into a 1ml syringe. An ultraviolet light source is installed on one side of the syringe. The horizontal distance from the ultraviolet light source to the syringe is 17cm, the ve...

Embodiment 8~9

[0051] A transparent conductive ball, the preparation process of which is basically the same as that of Example 1, the difference is that the components of the polymerizable deep eutectic solvent used are different, see Table 2 for details.

[0052] Table 2

[0053] Example hydrogen bond acceptor hydrogen bond donor Molar ratio (hydrogen bond acceptor: hydrogen bond donor) Example 8 betaine monohydrate acrylic acid 1:2 Example 9 ammonium chloride acrylic acid 1:2

Embodiment 10~14

[0055] A transparent conductive pellet, the preparation process of which is basically the same as that of Example 1, the difference is that the process parameters of the injection preparation and polymerization molding processes are different, see Table 3 for details.

[0056] table 3

[0057]

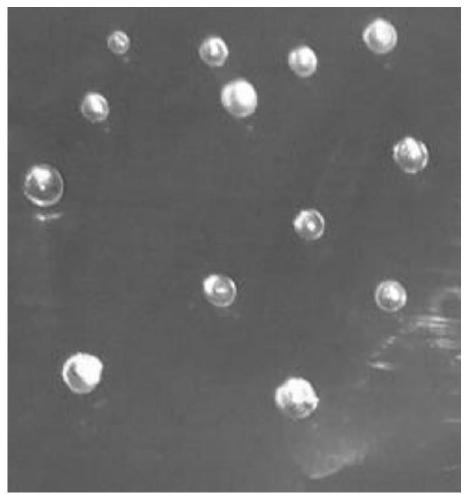

[0058] The diameter of the transparent conductive beads prepared in Examples 1 to 14 is about 2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com