Ternary positive electrode material, preparation method thereof and lithium ion battery

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of rate performance and cycle performance that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] In this embodiment, the ternary positive electrode material is prepared according to the following method:

[0072] (1) Put the mixture of orthoboric acid and cobalt nitrate into the high-speed mixer (referred to as the high-speed mixer) at a molar ratio of B:Co of 1:1, and its volume occupies 1 / 5 of the volume of the high-mixer (that is, the filling capacity is 1 / 5), and mixed at a speed of 100rpm for 0.5h, filled in a sagger, and then placed in a kiln to raise the temperature to 400°C at 5°C / min, keep warm for 5h, and feed 1L / h nitrogen into the kiln. After the sintering is completed, crush and sieve through a 325-mesh sieving machine to obtain Co 2 B 2 o 5 .

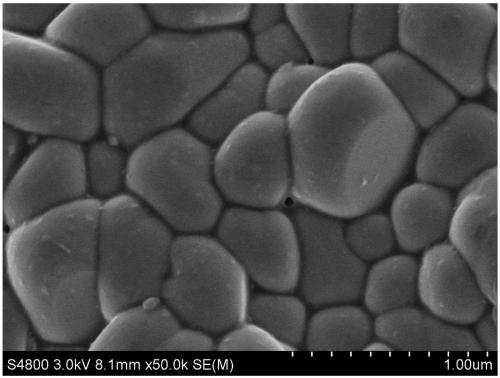

[0073] (2) will Co 2 B 2 o 5 With the high nickel ternary material Li with an average particle size of 3 μm 1.01 Ni 0.8 co 0.1 mn 0.1 o 2 According to the mass ratio of 0.001:1 and the filling amount of 1 / 5, mix it on a high-speed mixer at a speed of 50rpm for 1 hour, fill it in a sagger, and then p...

Embodiment 2

[0078] In this embodiment, the ternary positive electrode material is prepared according to the following method:

[0079] (1) The mixture of boron oxide and cobalt hydroxide is mixed in a high-speed mixer at a speed of 50 rpm for 2 hours at a molar ratio of B:Co of 1:1 and a filling amount of 3 / 4, then filled in a sagger, and placed Raise the temperature to 600°C at a rate of 5°C / min in the kiln, keep the temperature for 3h, and pass 5L / h argon into the kiln. After the sintering is completed, crush and sieve through a 325-mesh sieving machine to obtain Co 2 B 2 o 5 .

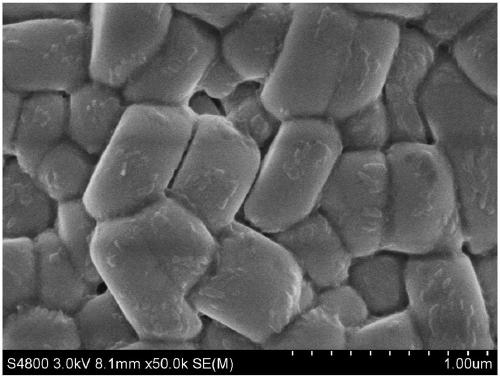

[0080] (2) will Co 2 B 2 o 5 With the high-nickel ternary material Li with an average particle size of 15 μm 0.95 Ni 0.6 co 0.2 mn 0.2 o 2 According to the mass ratio of 0.005:1 and the filling amount of 3 / 4, mix it on a high-speed mixer at a speed of 100rpm for 1 hour, fill it in a sagger, and then place it in a kiln to raise the temperature to 500°C at 5°C / min and keep it warm for 10h , Air is int...

Embodiment 3

[0084] In this embodiment, the ternary positive electrode material is prepared according to the following method:

[0085] (1) The mixture of tetraboric acid and cobalt carbonate is mixed in a high-speed mixer at a speed of 60rpm for 1h at a molar ratio of B:Co of 1:1 and a filling amount of 3 / 5, then filled in a sagger, and placed in a The temperature in the kiln is raised to 500°C at 3°C / min, and the temperature is kept for 4h, and 10L / h of carbon dioxide is introduced into the kiln. After the sintering is completed, crush and sieve through a 325-mesh sieving machine to obtain Co 2 B 2 o 5 .

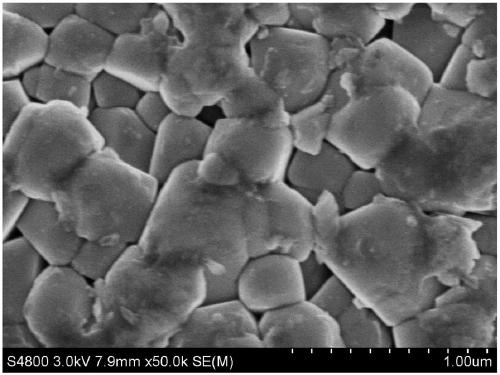

[0086] (2) will Co 2 B 2 o 5 With the high-nickel ternary material Li with an average particle size of 10 μm 1.0 Ni 0.65 co 0.15 mn 0.20 o 2 According to the mass ratio of 0.003:1 and the filling amount of 3 / 4, mix it on a high-speed mixer at a speed of 70rpm for 1.5h, fill it in a sagger, and then place it in a kiln to raise the temperature to 300°C at 3°C / min and keep it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com