Water-based self-emulsifying organic sulfur-phosphorus pesticide microcapsule and preparation method thereof

An organic sulfur-phosphorus and self-emulsifying technology is applied in the field of preservation of animal and plant bodies or their parts, which can solve the problems of difficulty in controlling the strength of capsule materials, difficulty in achieving release effect, etc., and achieves good emulsification effect, not easy to settle, and good dissolution sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

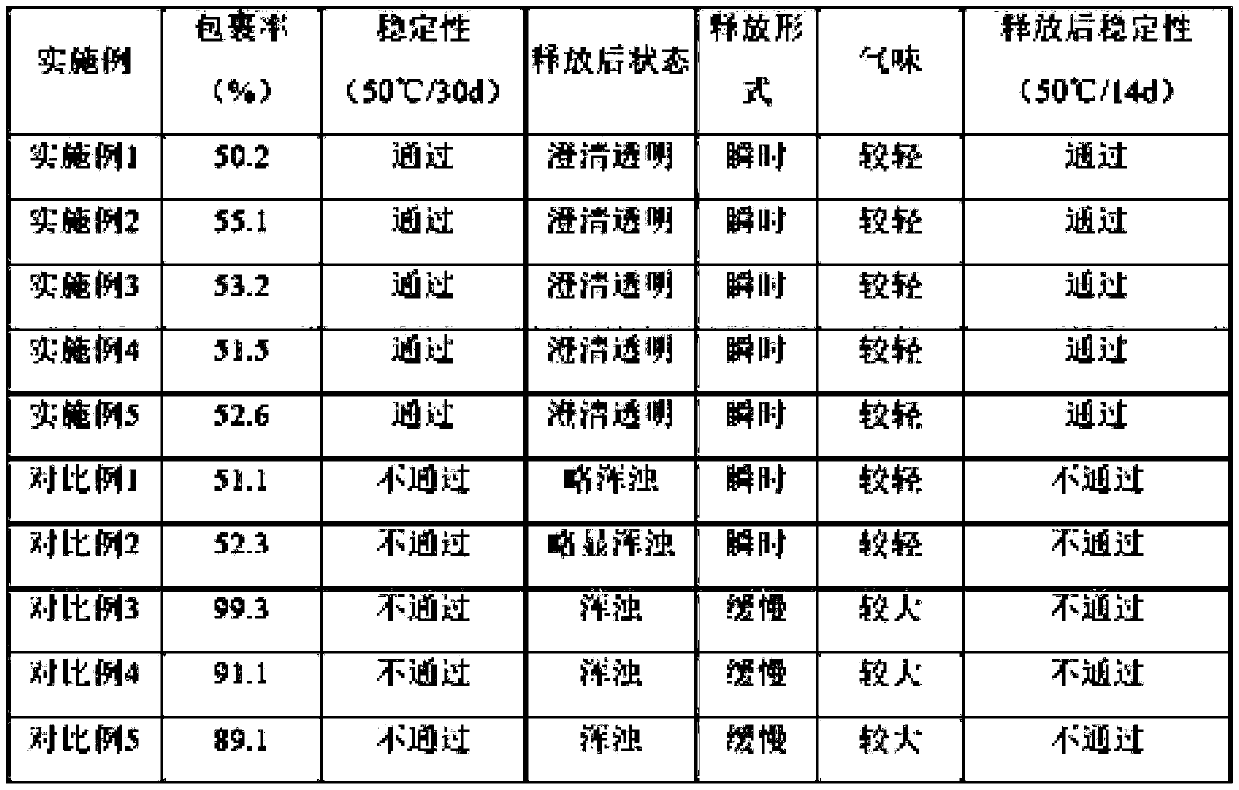

Examples

preparation example Construction

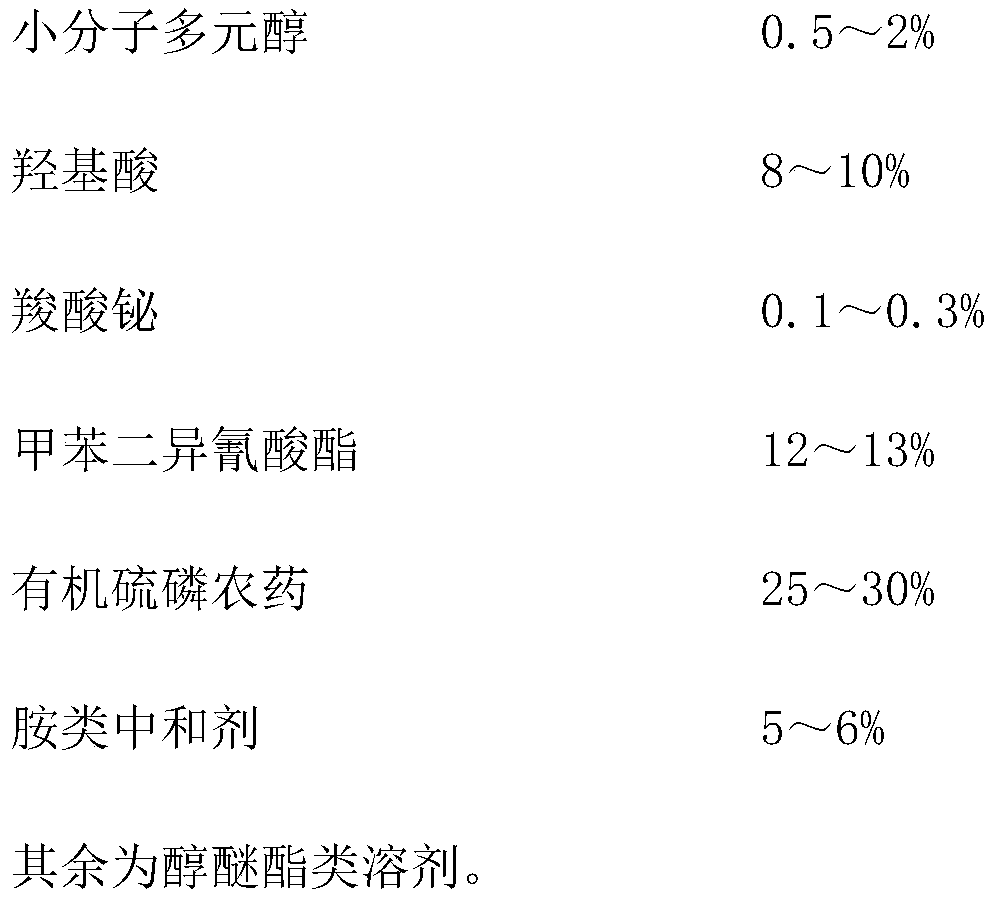

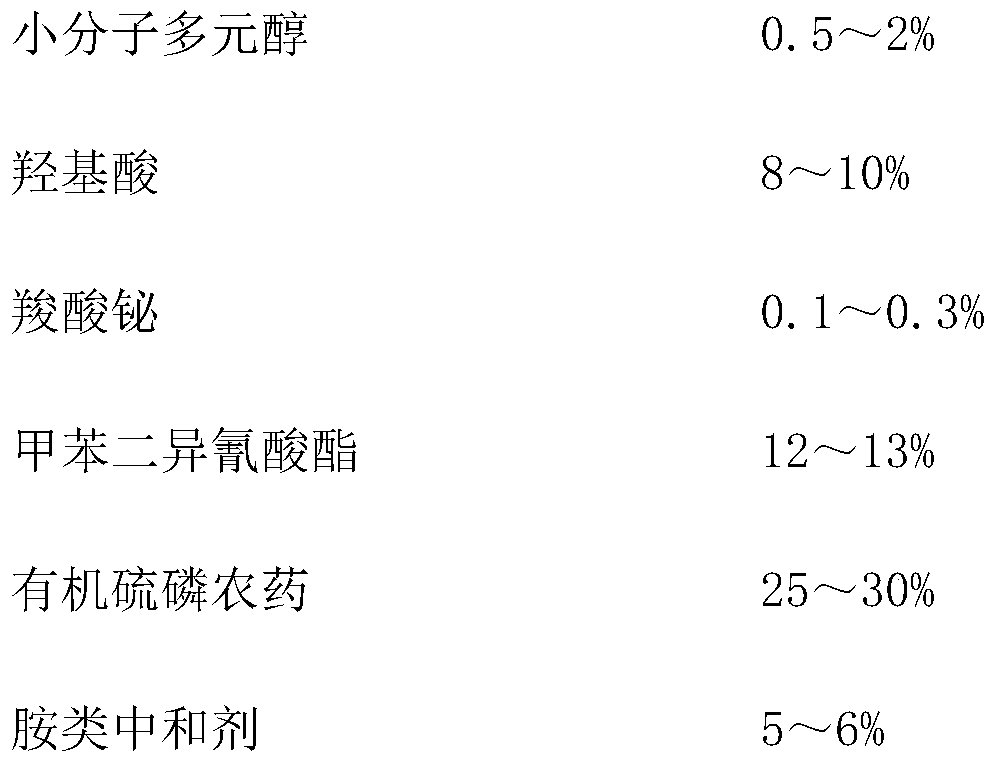

[0038] (2) Preparation of prepolymer: in step (1), 20-40% of the total mass of small molecule polyol, 20-40% of the total mass of hydroxyacid, 20-40% of the total mass of toluene diisocyanate and carboxyl Bismuth acid is dissolved in alcohol ether ester solvents and polymerized to form a small molecule polymer solution;

[0039] (3) Preparation of the capsule core: adding the organothion pesticide to the small molecule polymer solution prepared in step (2), stirring and mixing evenly to obtain the first mixed solution;

[0040] (4) Preparation of microcapsules: Add the remaining small molecule polyols and hydroxy acids to the first mixed solution prepared in step (3), mix evenly to obtain the second mixed solution, stir the second mixed solution and heat up to 80°C , then slowly add the remaining toluene diisocyanate, stir until the reaction is complete, then add an amine neutralizer, stir to cool down to room temperature, and discharge to obtain microcapsules.

[0041] The o...

Embodiment 1

[0044] Example 1: 1.9 parts by mass of ethylene glycol, 9.9 parts by mass of bismethylolpropionic acid, 0.001 parts by mass of bismuth carboxylate, 12.9 parts by mass of toluene diisocyanate, 25.1 parts by mass of fenitrothion, and 5 parts by mass of dimethylethanolamine , and the rest are propylene glycol methyl ether acetate, a total of 100 parts by mass.

Embodiment 2

[0045] Embodiment 2: 2 mass parts of glycerol, 10 mass parts of bismethylolpropionic acid, 0.001 mass part of bismuth carboxylate, 13 mass parts of toluene diisocyanate, 25 mass parts of fenitrothion, 5.5 mass parts of ethanolamine, and the rest are Dipropylene glycol methyl ether acetate, a total of 100 parts by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com