Preparation method of long-shelf-life brown viable bacteria type fermented milk and fermented milk

A technology for fermented milk and shelf life, which is applied to bacteria and lactobacilli used in dairy products and food preparation, which can solve the problem of the decrease in the number of viable bacteria, the deterioration of taste and texture, and the inability to achieve long shelf life of products containing live bacteria and other problems, to achieve the effect of delicate taste, rich nutrition and unique pleasant flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

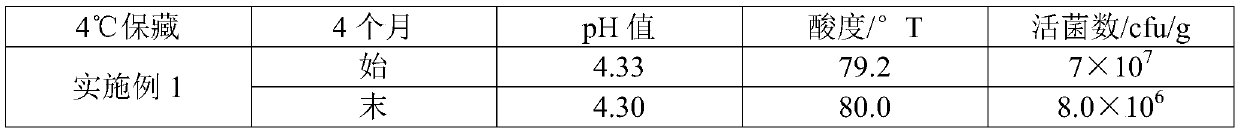

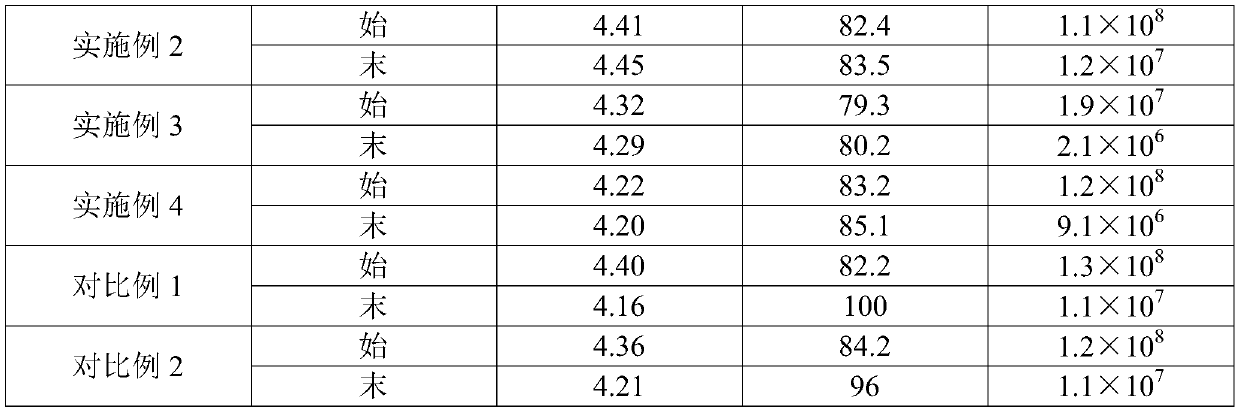

Examples

Embodiment 1

[0052] Raw material (according to 1000g fermented milk raw material):

[0053] Milk powder 80g, fructose 70g, starch 19.9g, pectin 0.1g, food flavor 0.05g, diacetyl tartrate mono-diglyceride 0.1g, condensed milk 20g, cream 10g, sodium citrate 0.1g, starter 0.05g, Lactobacillus reuteri suspension 4g, water 795.7g.

[0054] Process steps:

[0055](1) Add water into the milk tank, add weighed milk powder, fructose, condensed milk, cream, sodium citrate under stirring state, dissolve all in water and continue stirring for 20 minutes, control the water temperature during the whole process At 60°C, then the temperature of the feed liquid is raised to 95°C, and the pressure is increased to 20MPa, and kept for 30 minutes, browning until browning milk;

[0056] (2) Cool the browned milk to 60°C, add diacetyl tartaric acid mono-diglyceride, pectin, starch, and food flavor under stirring, stir for 20 minutes, and then homogenize, the homogenization temperature is 65°C, and the homogeni...

Embodiment 2

[0061] Raw material (according to 1000g fermented milk raw material):

[0062] Milk powder 100g, whey protein powder 20g, fructose 30g, starch 10g, agar 2g, pectin 0.5g, food flavor 1.5g, monoglyceride succinate 0.5g, condensed milk 40g, cream 20g, citric acid 0.2g, 0.15g of starter, 7g of Lactobacillus reuteri suspension, 783.15g of water.

[0063] Process steps:

[0064] (1) Add water into the milk tank, add weighed milk powder, fructose, condensed milk, cream, citric acid under stirring state, dissolve all in water and continue stirring for 25 minutes, control the water temperature during the whole process 50°C, then the temperature of the feed liquid is raised to 95°C, and the pressure is increased to 10MPa, and kept for 60 minutes, browning until browning milk;

[0065] (2) Cool the browned milk to 50°C, add monoglyceride succinate, pectin, starch, agar, whey protein powder, and food flavor under stirring, and stir for 15 minutes to obtain a fermentation substrate;

[...

Embodiment 3

[0071] Raw material (according to 1000g fermented milk raw material):

[0072] Whole milk protein powder 5g, fructose 20g, pectin 3g, monoglyceride succinate 0.2g, condensed milk 30g, cream 6g, lactic acid 1g, starter 0.12g, Lactobacillus reuteri suspension 1g, fresh goat milk 933.5g.

[0073] Process steps:

[0074] (1) Add the weighed fructose, condensed milk, cream, and sodium citrate into the fresh goat milk while stirring, and continue stirring for 30 minutes after all are dissolved. During the whole process, the water temperature is controlled at 40°C, and then the temperature of the feed liquid is raised to 90°C, pressurized to 5MPa, and kept for 120 minutes, browning until browned milk;

[0075] (2) Cool the browned milk to 45°C, add monoglyceride succinate, pectin, and whole milk protein powder under stirring, and stir for 10 minutes to obtain a fermentation substrate;

[0076] (3) Homogenize the fermentation substrate with a homogenization temperature of 60° C. an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com