Method for preparation of furoic acid from furfural

A technology of furfural and furoic acid, which is applied in the field of chemical substance preparation, can solve problems such as high price, influence on product color, and limited use, and achieve the effects of mild reaction conditions, increased selectivity, and reduced by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of method that furfural prepares furoic acid, carries out as follows:

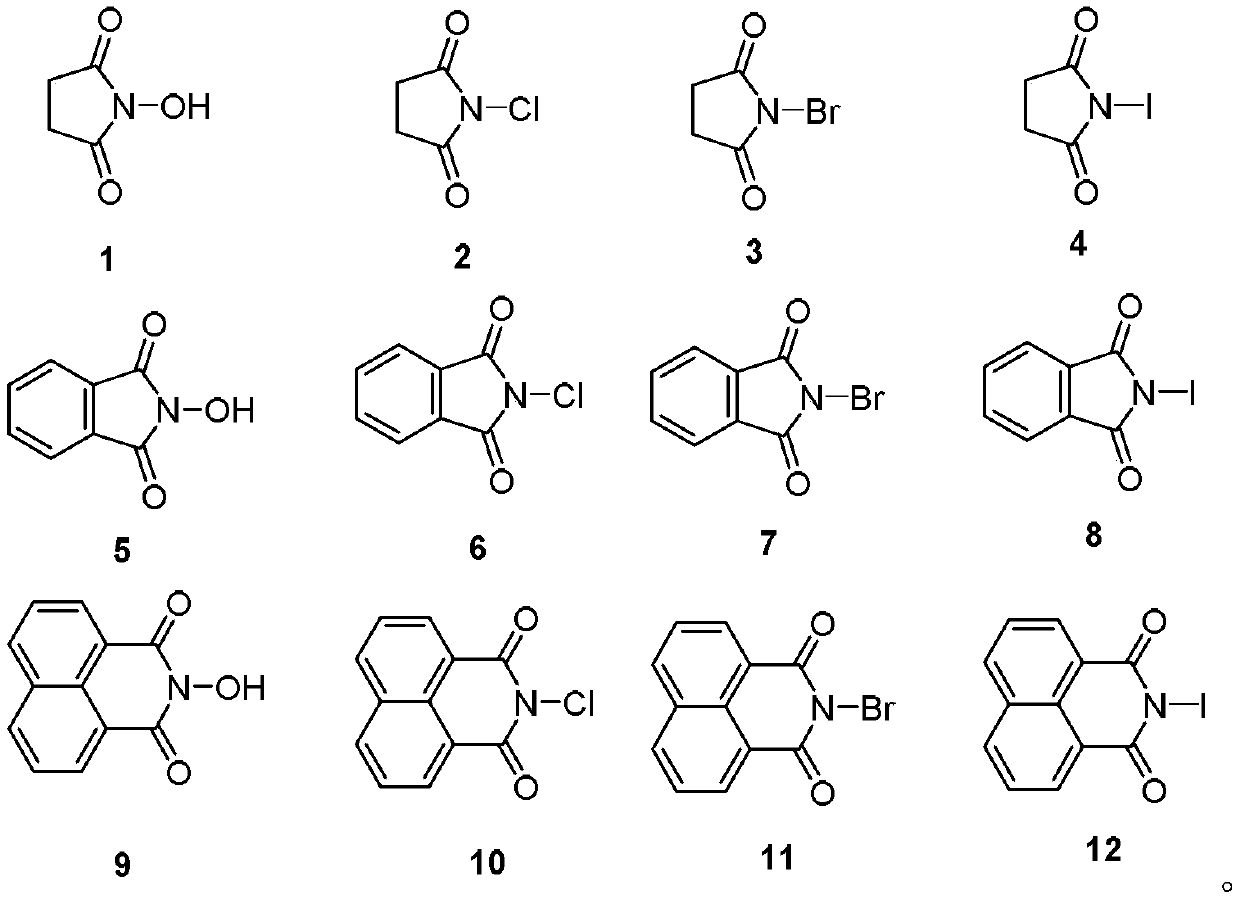

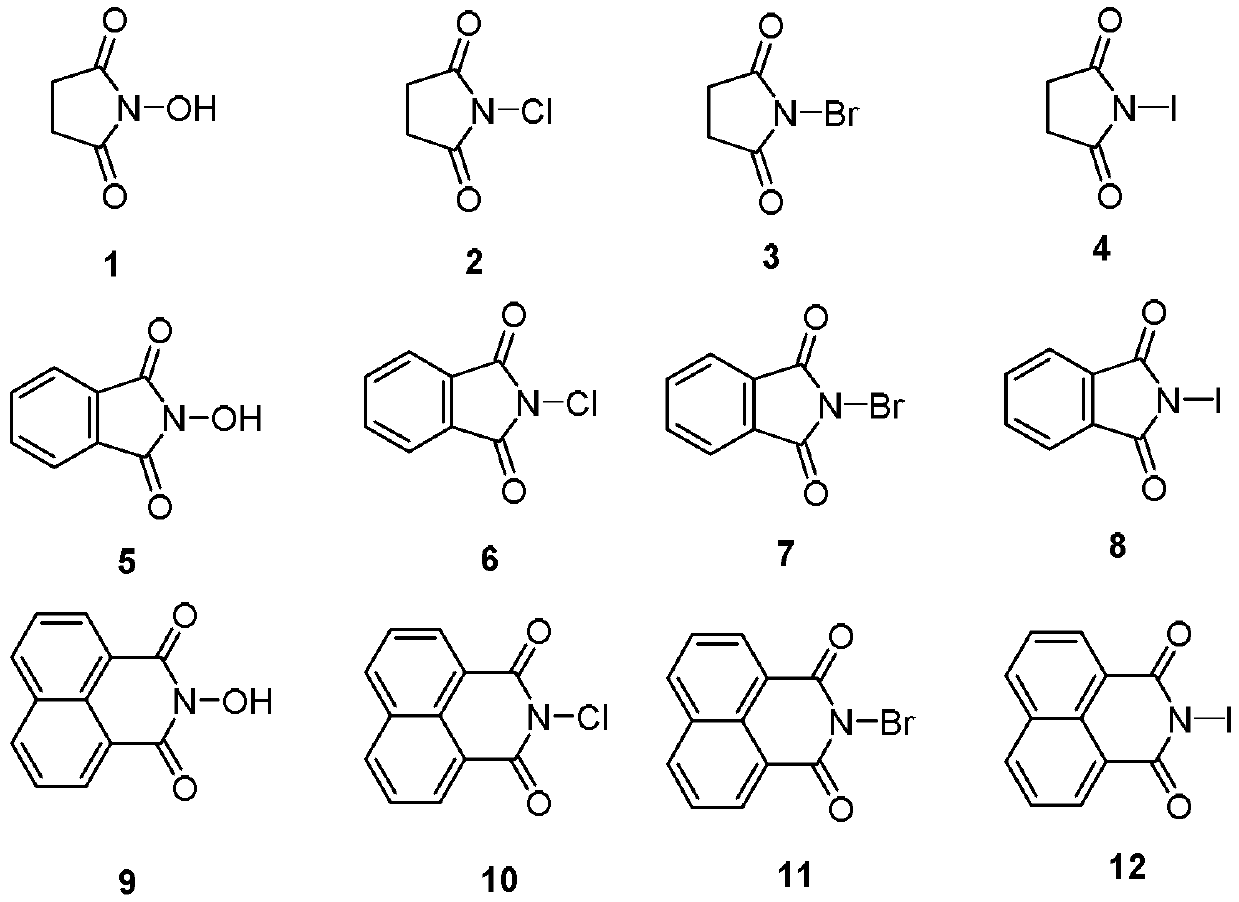

[0021] Get 1mmol of furfural, 10mL of acetonitrile and 10mol% catalyst 1 (calculated by the number of moles of furfural) and join in a 25ml autoclave. React at 50°C for 24 hours. After the reaction, cool to room temperature, add N,N-dimethylformamide as an internal standard, dilute with methanol, and detect by gas chromatography. The specific detection conditions are as follows: GC (2104, Shimazu, FID) A DB-FFAP (30m x 0.25μm x 0.32mm) chromatographic column was assembled to detect the product content. The vaporization temperature was set at 270°C, the detection temperature was set at 270°C, the oven temperature was set at 120°C for 1 min, and the temperature was raised to 230°C for 8 min and kept for 8 min. The yield of furoic acid was 81%.

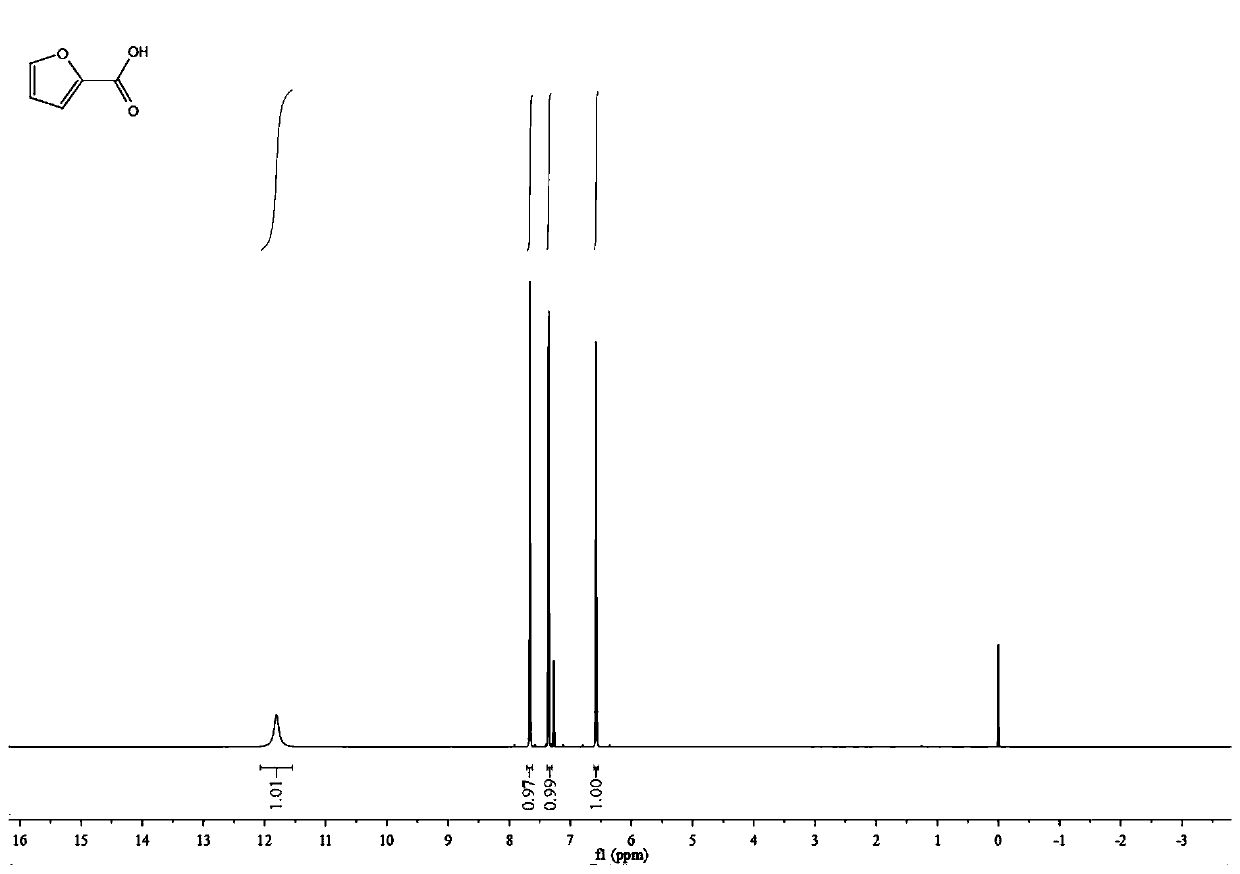

[0022] The H NMR spectrum of furoic acid figure 1 shown. 1 H NMR (400MHz, CDCl 3 )δ11.80(s,1H),7.66(dd,J=1.7,0.8Hz,1H),7.35(dd,J=3.5,0.8Hz,1H),6.5...

Embodiment 2

[0024] Acetonitrile was changed to nitromethane, other conditions were the same as in Example 1, and the yield of furoic acid was 83%.

Embodiment 3

[0026] Acetonitrile was changed to water, and the time was extended to 48h, other conditions were the same as in Example 1, and the yield of furoic acid was 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com