A kind of preparation method of polymerized hemoglobin with low polymer content

A technology of hemoglobin and inert gas is applied in the field of preparation of polymerized hemoglobin with low polymer content, which can solve the problems of affecting hemodynamic characteristics and tissue oxygen supply capacity, reducing the effective utilization rate of hemoglobin, and large molecular weight of polymerized hemoglobin, etc. The risk of pollution and endotoxin exceeding the standard, the risk of reducing renal toxicity and vasoconstriction, the effect of easier application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

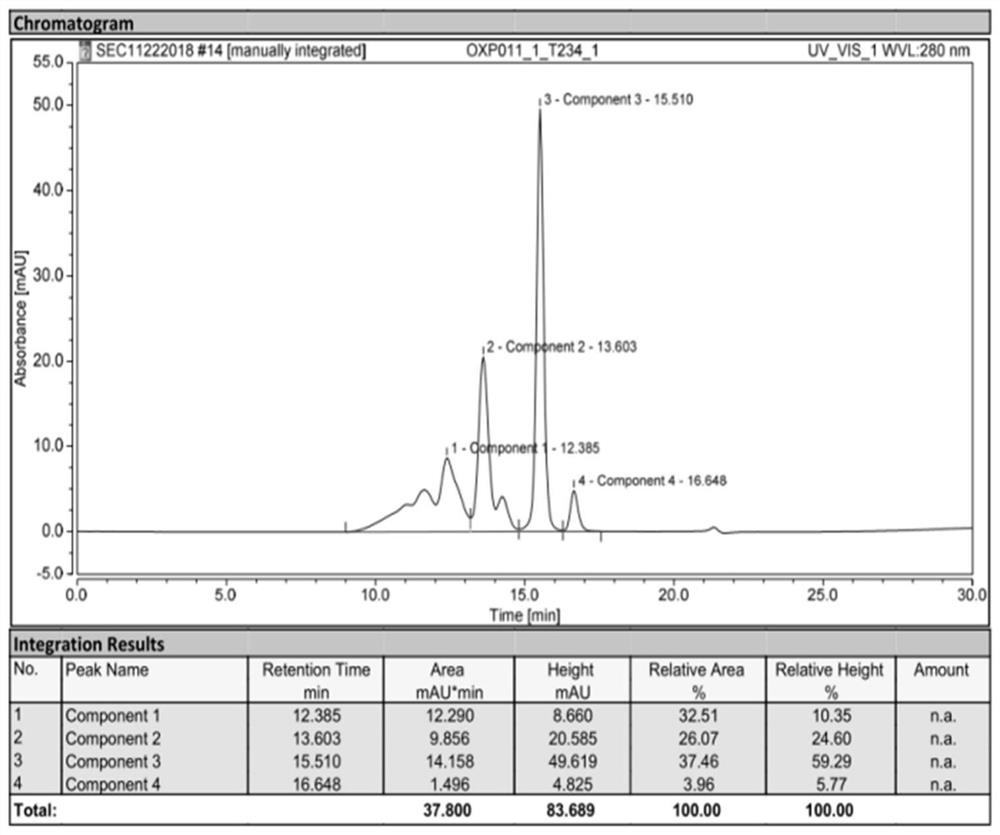

[0237] 2.3 Preparation of buffer required for detection:

[0238] Prepare buffer 750mM MgCl as follows 2 , 50 mM tris, 0.1 mM EDTA pH 6.5.

[0239] 2.3.1 Measure 800mL of ultrapure water with a 1000mL graduated cylinder and transfer it to a 1L beaker.

[0240] 2.3.2 Add 10.46±0.05g of Bis-Tris to a 1L beaker and stir gently with a magnetic stirring bar until completely dissolved.

[0241] 2.3.3 Adjust the pH of the solution to 6.7±0.1 with concentrated hydrochloric acid, and stir gently.

[0242] 2.3.4 Add 152.48±0.05g of MgCl to the 1L beaker 2 6H2O.

[0243] 2.3.5 Add 0.030±0.001g of EDTA to a 1L beaker and stir gently with a magnetic stirring bar until it is completely dissolved.

[0244] 2.3.6 Adjust the pH of the solution to 6.5±0.1 with concentrated hydrochloric acid, and stir gently.

[0245] 2.3.7 Adjust the pH to the required range, use a 1000ml graduated cylinder, and increase the volume to 1000ml with ultrapure water.

[0246] 2.3.8 Filter the solution using ...

Embodiment 1

[0266] The preparation of embodiment 1 cross-linked hemoglobin

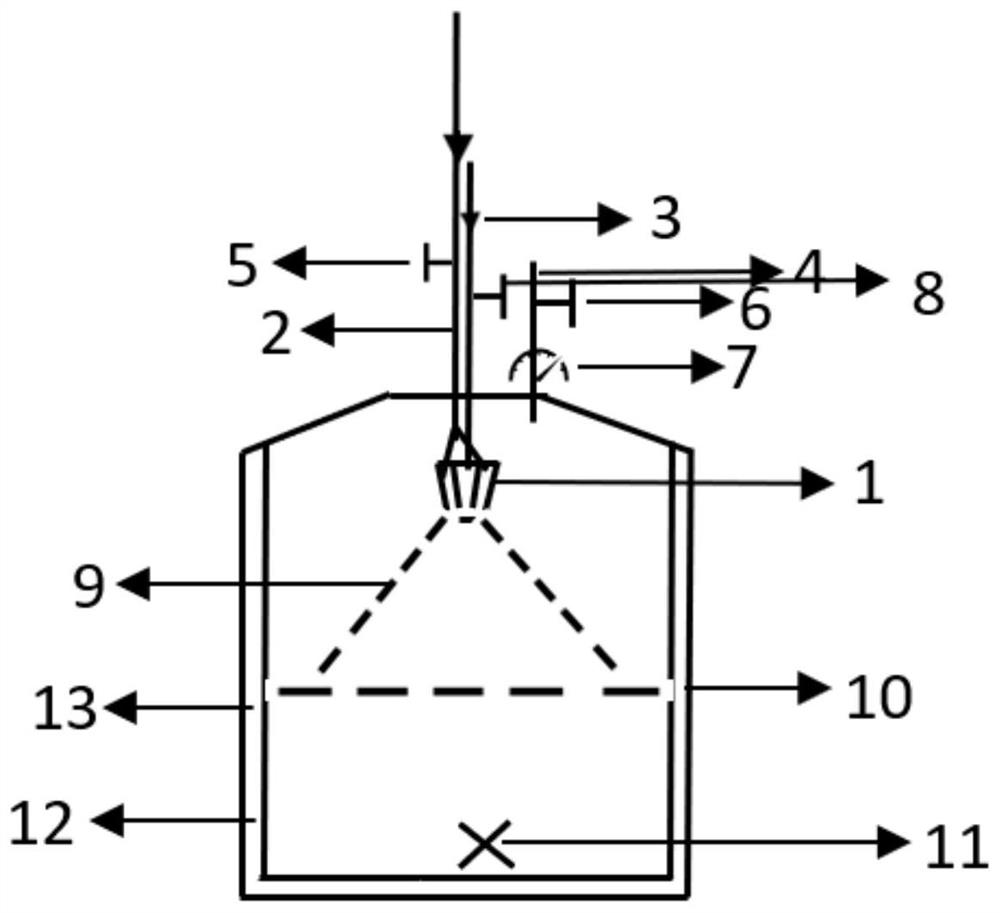

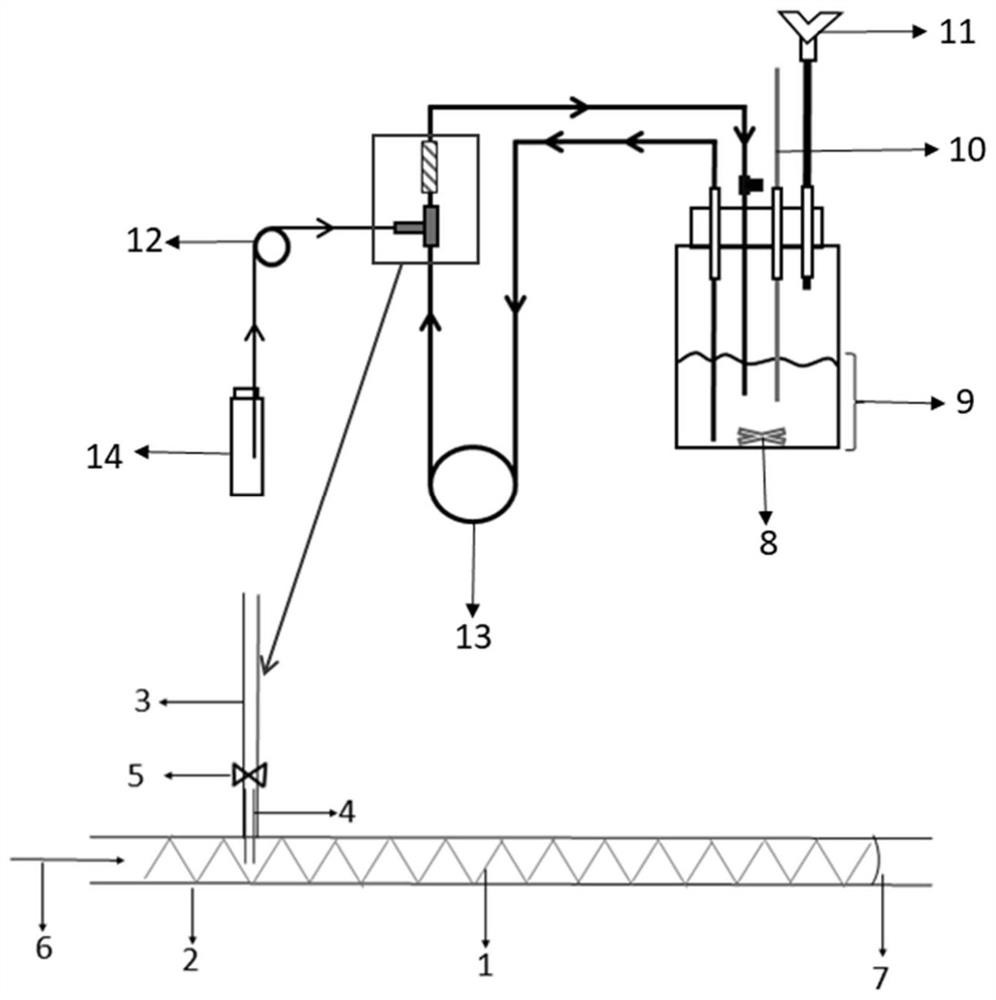

[0267] like figure 1 As shown, dilute the deoxygenated hemoglobin to 2g / dL, add NAC with a final concentration of 3mg / mL, and move it into the anaerobic reaction vessel 12. The height of its liquid level 10 should not exceed half of the height of the anaerobic reaction vessel 12. The pressure atomizer 1 is fixed on the top of the oxygen reaction vessel 12, the inlet pipe 3 and the liquid inlet pipe 2 are connected to the atomizer 1, and the balance gas pipeline 4 is connected to the top of the anaerobic reaction vessel 12 to adjust the internal pressure of the anaerobic reaction vessel 12. required pressure, close the anaerobic reaction vessel 12, open the bottom stirring rotor 11, heat the reaction solution to 42°C through the water bath jacket 13, open the liquid inlet pipe valve 5, add the cross-linking agent glutaraldehyde, adjust the liquid inlet speed to 260mL / min, open the inlet pipe valve 8, feed an in...

Embodiment 2

[0270] The preparation of embodiment 2 cross-linked hemoglobin

[0271] like figure 1 As shown, dilute the deoxygenated hemoglobin to 3g / dL, add NAC with a final concentration of 3mg / mL, and move it into the anaerobic reaction vessel 12. The height of its liquid level 10 should not exceed half of the height of the anaerobic reaction vessel 12. The pressure atomizer 1 is fixed on the top of the oxygen reaction vessel 12, the inlet pipe 3 and the liquid inlet pipe 2 are connected to the atomizer 1, and the balance gas pipeline 4 is connected to the top of the anaerobic reaction vessel 12 to adjust the internal pressure of the anaerobic reaction vessel 12. required pressure, close the anaerobic reaction vessel 12, open the bottom stirring rotor 11, heat the reaction solution to 42°C through the water bath jacket 13, open the liquid inlet pipe valve 5, add the crosslinking agent glutaraldehyde, adjust the liquid inlet speed to 500mL / min, open the inlet pipe valve 8, feed an ine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com