Mutagenization method for Aspergillus oryzae with hereditary stability

A technology of genetic stability and treatment method, which is applied in the field of mutagenesis treatment of Aspergillus oryzae, can solve the problems of huge difference in fermentation performance and unstable genetic traits of mutagenized strains, and achieves wide mutation spectrum, good genetic stability and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present embodiment provides a kind of mutagenesis treatment method of Aspergillus oryzae with genetic stability, specifically as follows:

[0025] Step 1, strain activation: Aspergillus oryzae As 3.042 was inoculated in soybean juice medium, and cultured at 30°C for 3 days;

[0026] Soybean juice medium composition is: dipotassium hydrogen phosphate 0.10%, magnesium sulfate 0.05%, soluble starch 2%, ammonium sulfate 0.05%, agar 1.5%, dissolve in soybean juice to 100ml, adjust pH to 6.8.

[0027] Step 2, preparation of the bacterial suspension: elute the bacterial cells from the medium with 15 mL of normal saline, filter through 4 layers of gauze into a 100 mL Erlenmeyer flask filled with glass beads, seal with eight layers of gauze, and shake at 120 rpm for 60 min;

[0028] Step 3, ARTP mutagenesis: take 1mL of the processed Aspergillus oryzae suspension and put it in a fixed position of the ARTP (room temperature isobaric plasma) mutagenesis instrument, set the pow...

Embodiment 2

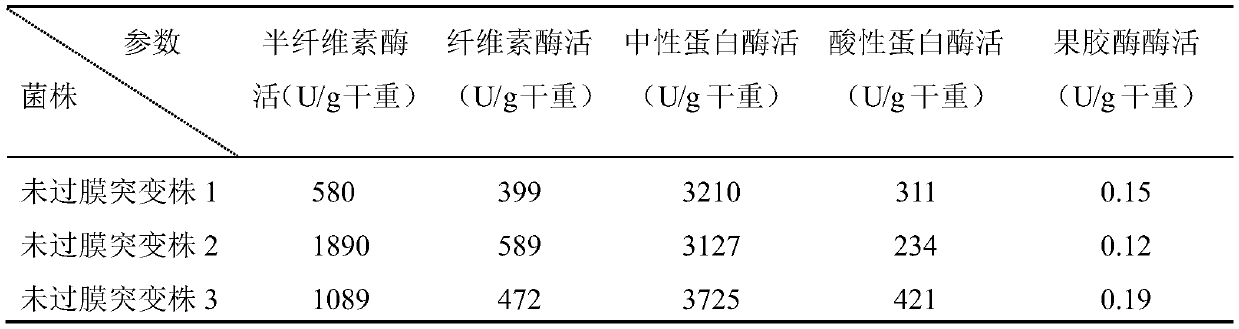

[0039] The present embodiment provides a kind of mutagenesis treatment method of Aspergillus oryzae with genetic stability, and the scheme is summarized as follows, and the difference with embodiment 1 is that there is no sterile membrane filtration step described in step 4:

[0040] The initial screened Aspergillus oryzae As 3.042 was used as the starting strain, and after activation, it was prepared as a bacterial suspension, and the mutagenesis was carried out with room temperature isobaric plasma (ARTP), and the Aspergillus oryzae suspension was placed in a fixed position of the ARTP mutagenesis instrument. , when the air flow rate was 10SLM, the mutagenesis treatment time was set to 165s to obtain mutants, the mutant bacterial suspension was transferred to 4mL screening medium I for cultivation for 48h, and the culture solution was transferred to a fully automatic high-throughput microbial drop culture instrument ( MicrobialMicrodropletCulturesystem, MMC) sampling bottle, ...

Embodiment 3

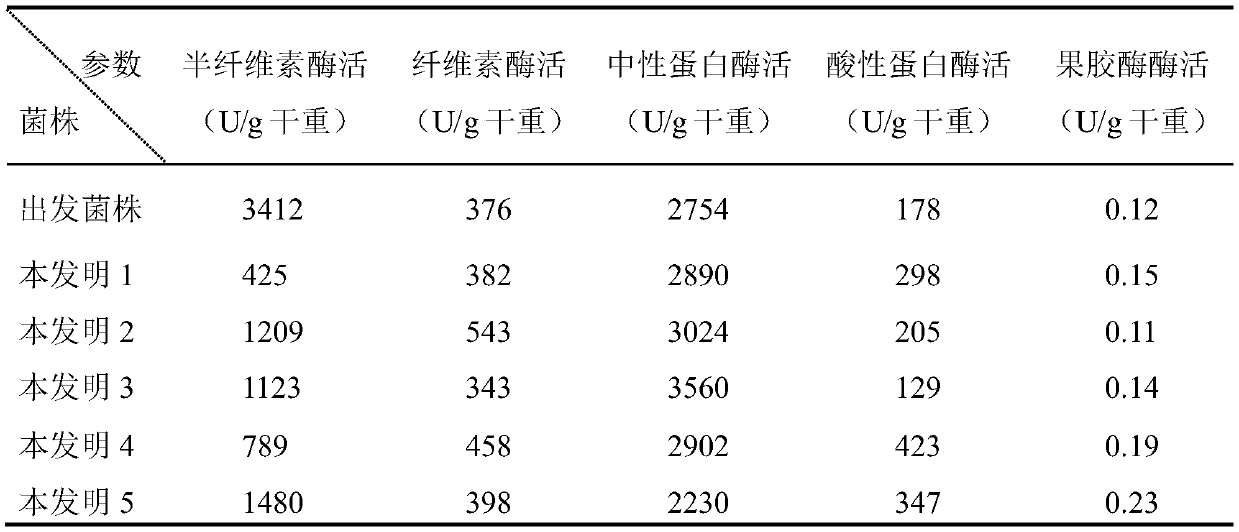

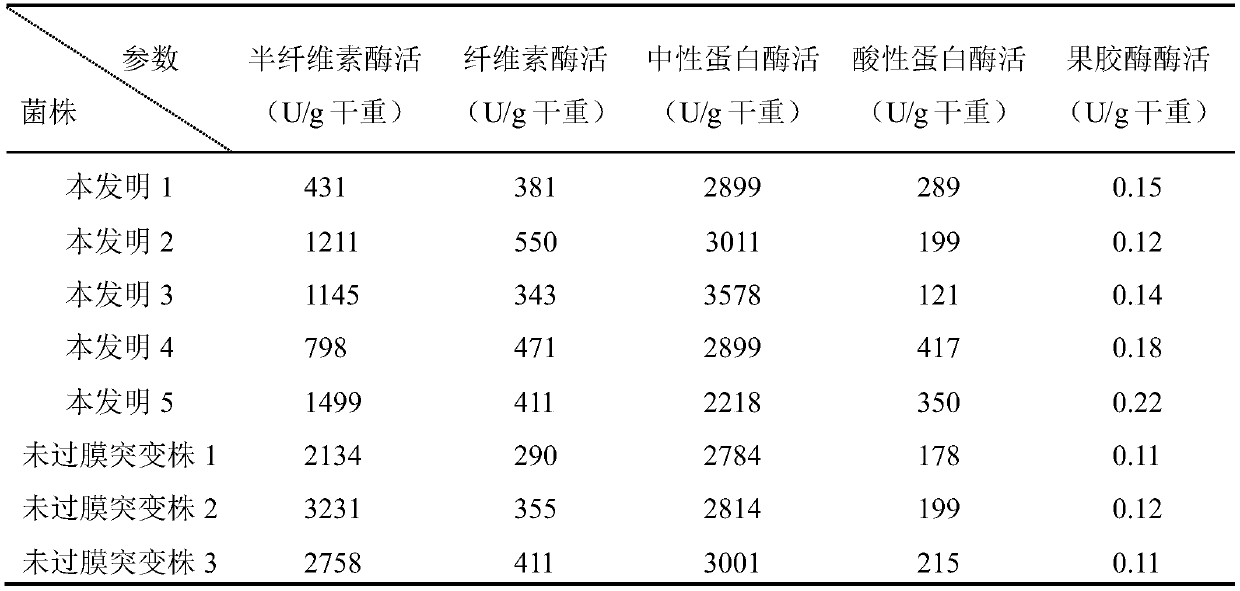

[0045] With the mononuclear Aspergillus oryzae mutant strain with genetic stability obtained in embodiment 1, the initial mutant strain after continuous passage and the fiftieth generation mutant strain fermentation koji-making rear relative enzyme activity stability verification:

[0046] The mutant strains were inoculated on the slant of soybean medium, cultured at 30°C for 72 hours, and continuously passed for 50 generations.

[0047] Mix wheat flour, soybean meal, and water in a mass ratio of 3:7:7, sterilize at 121°C for 20 minutes, and cool to below 40°C. The fiftieth generation strain of the mutant strain was inserted into the material at a ratio of 0.6%, and cultured for 48 hours under the conditions of a controlled temperature of 30°C and a humidity of 95%, and the related enzyme activities in the finished koji were measured. The results are shown in Table 3.

[0048] Table 3 Detection of related enzyme activities of the fiftieth generation strains of membrane-passed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com