Lithium ion battery cathode material and preparation method thereof and lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in the field of lithium-ion battery positive electrode materials and their preparation, can solve problems such as low specific capacity, and achieve high energy density, good stability, and high particle consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

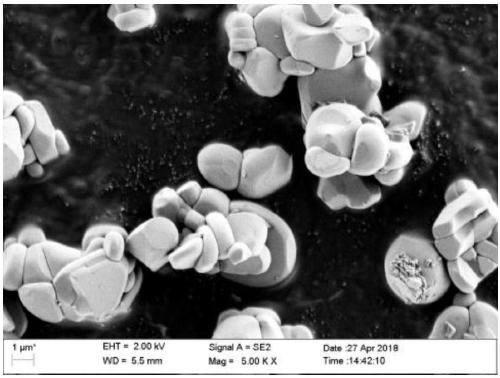

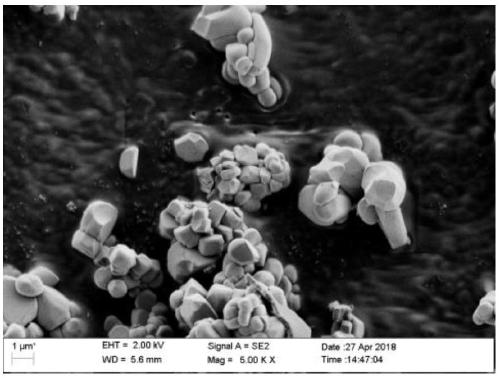

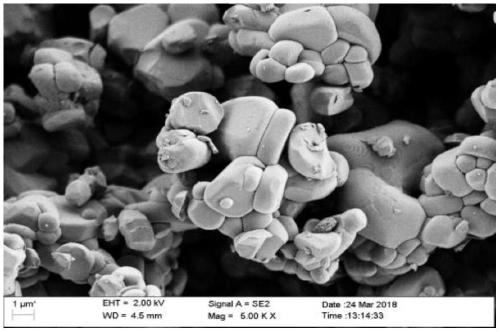

[0029] The preparation method of the positive electrode material of lithium ion battery of the present invention has certain requirements on the morphology and physical and chemical indicators of the ternary precursor, and its tap density should not be lower than 1.5g / cm 3 , the specific surface area is not less than 10m 2 / g, the morphology should be spherical or spherical precursor particles formed by the aggregation of blade-like primary particles.

[0030] The lithium source used in the preparation method of the lithium ion battery positive electrode material of the present invention is at least one of lithium nitrate, lithium acetate, lithium oxide, lithium oxalate, lithium hydroxide monohydrate or lithium carbonate.

[0031] The atmosphere used during sintering during the preparation process of the positive electrode material of the lithium ion battery of the present invention is an aerobic atmosphere, and oxygen or air can be used.

[0032] The lithium ion battery posi...

Embodiment 1

[0035] The preparation method of the present embodiment comprises the following steps:

[0036] (1) The ternary precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 (Ningxia Dongfang Tantalum Co., Ltd.), Lithium Carbonate, B 2 o 3 After mixing evenly in a high-speed mixer, sintering at 930°C for 5.5h in an air atmosphere to obtain an intermediate product; the amount of Li in lithium carbonate and the sum of the amounts of Ni, Co and Mn in the ternary precursor The ratio is 1.02:1, B 2 o 3 The mass of the ternary precursor is 0.1% of the mass of the ternary precursor; the tap density of the ternary precursor used is 1.76g / cm 3 , D50 is 3.68μm, specific surface area is 13.9m 2 / g;

[0037] (2) The resulting intermediate product is crushed through a 325 mesh sieve, then lithium hydroxide monohydrate is added so that the ratio of the amount of Li to the sum of the amount of matter of Ni, Co, and Mn is 1.08:1, and mixed uniformly It can be obtained by sintering at 950°C for 7h in an air...

Embodiment 2

[0039] The preparation method of the present embodiment comprises the following steps:

[0040] (1) The ternary precursor Ni 0.83 co 0.07 mn 0.1 (OH) 2 (Ningxia Dongfang Tantalum Co., Ltd.), Li 2 CO 3 , AlF 3 After mixing evenly in a high-speed mixer, sintering at 800°C for 10 hours in an air atmosphere to obtain an intermediate product; the ratio of the amount of Li in lithium carbonate to the sum of the amounts of Ni, Co, and Mn in the ternary precursor 1.0:1, B 2 o 3 The mass of the ternary precursor is 0.2% of the mass of the ternary precursor; the tap density of the ternary precursor used is 1.82g / cm 3 , D50 is 4.1μm, specific surface area is 14.2m 2 / g;

[0041] (2) The resulting intermediate product is crushed through a 325 mesh sieve, then lithium hydroxide monohydrate is added so that the ratio of the amount of Li to the sum of the amount of matter of Ni, Co, and Mn is 1.05:1, and mixed uniformly Sintered at 850°C for 12h in an air atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com