Titanizing process for superhard material micro powder

A super-hard material and titanium plating technology, which is applied in metal material coating process, sputtering plating, ion implantation plating, etc., can solve the problem of low bonding force between coating and diamond particles, large consumption of plating metal, and plating efficiency Low-level problems, to achieve the effect of improving single grinding efficiency, increasing single grinding amount, and good particle consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The embodiment of the present invention provides a titanium plating process of cubic boron nitride micropowder with a particle size of 2 to 4 microns, which specifically includes the following steps:

[0035] Raw material classification: 325-mesh titanium powder is classified into 325 mesh titanium powder in pure water according to the production process of cubic boron nitride micropowder according to the sedimentation method, and is divided into 5 titanium powder raw material groups according to the principle of concentrated and accurate particle size range and no coarse and fine particles. Laser The particle size analyzer respectively detects the five titanium powder raw material groups, among which, there is a titanium powder raw material group whose particle size ranges from 10 to 20 microns, and its D10 value is 10 microns, and its D90 value is 20 microns;

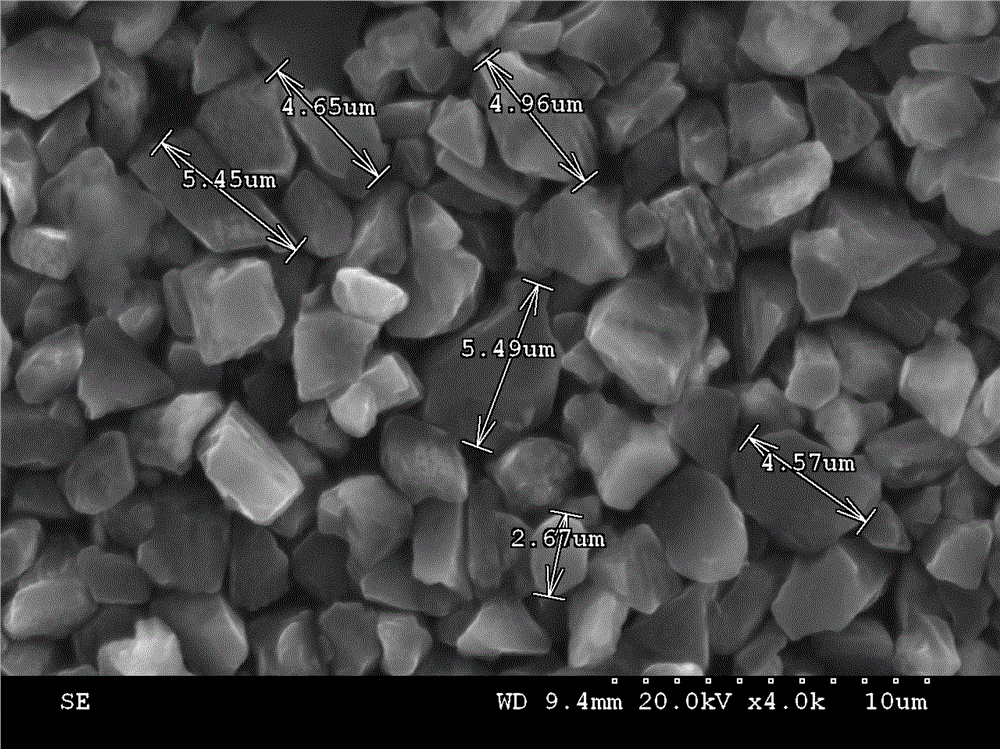

[0036] Titanium powder coating material selection: the particle size of cubic boron nitride micropowder is 2 ...

Embodiment 2

[0044] The titanium plating process of the cubic boron nitride micropowder provided in this embodiment is basically the same as the titanium plating process provided in Example 1, the difference being that the particle size range of the cubic boron nitride micropowder is 5 to 10 microns. A raw material group of titanium powder with a particle size ranging from 15 to 30 microns, and use it as a titanium powder coating material; in the step of vacuum evaporation, control the holding temperature to 790 ° C, and the holding time is 110 minutes; in the process of grinding the crude product , The grinding time is 110 minutes; the recovery rate of titanium powder plating is 99.5%.

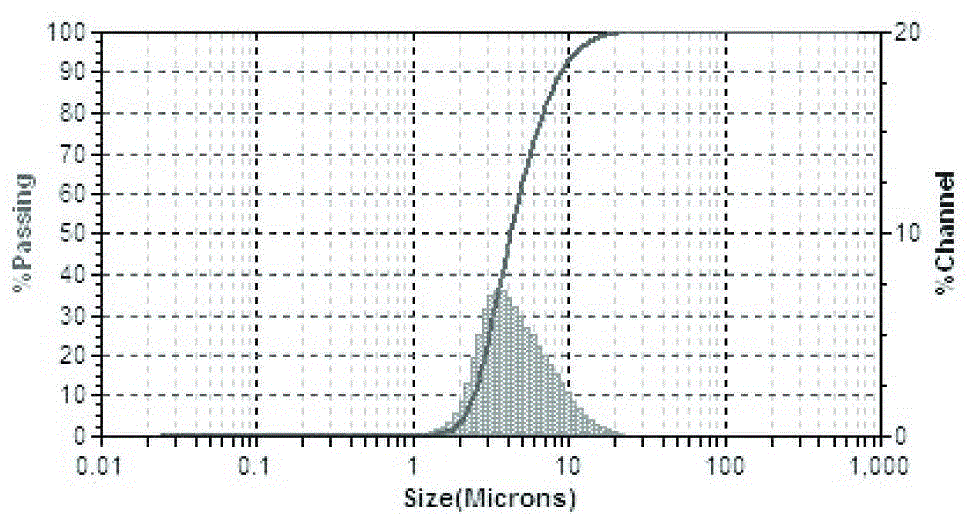

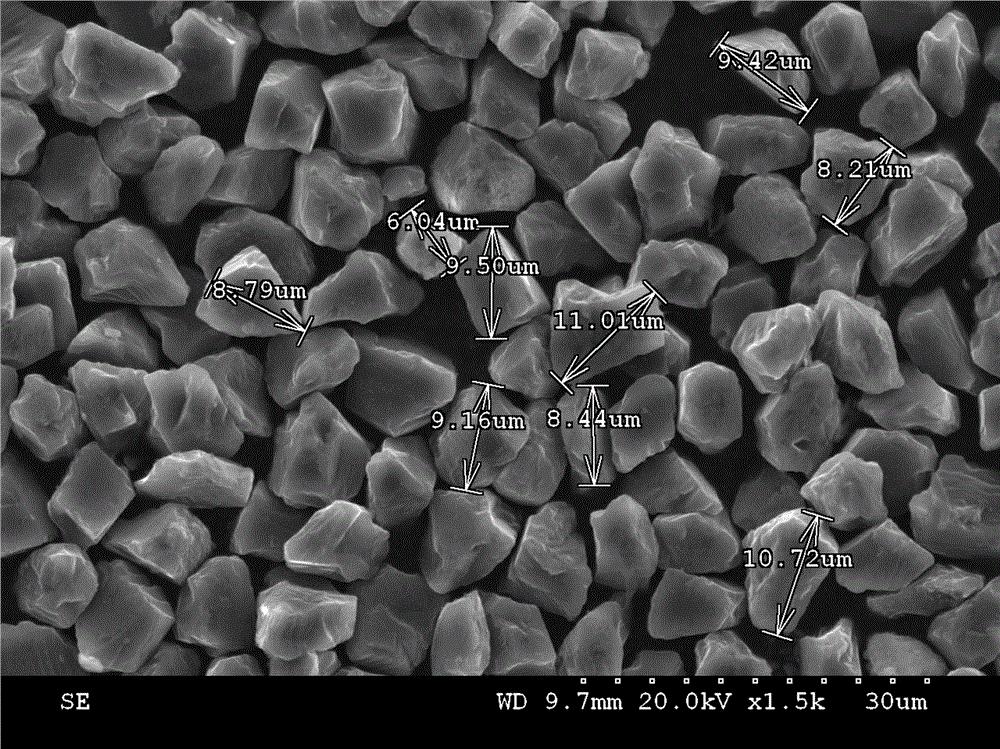

[0045] The scanning electron microscope photograph of the finished product of titanium-coated cubic boron nitride particles prepared by the present embodiment is as follows: image 3 shown. Adopt particle size distribution analyzer to detect the particle size of the finished product of titanium-coated cu...

Embodiment 3

[0047] The titanium plating process of the cubic boron nitride micropowder provided in this embodiment is basically the same as the titanium plating process provided in Example 1, the difference being that the particle size range of the cubic boron nitride micropowder is 10 to 20 microns. A titanium powder raw material group with a particle size ranging from 25 to 40 microns, and use it as a titanium powder coating; in the step of vacuum evaporation, control the holding temperature to 800 ° C, and the holding time is 120 minutes; in the process of grinding the crude product , The grinding time is 100 minutes; the recovery rate of titanium powder plating is 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com