Method for preparing antarctic krill enzymatic hydrolysate through subcritical extraction and enzymolysis

An Antarctic krill and enzymatic hydrolysis solution technology, which is applied in the fields of application, fish protein composition, fat oil/fat production, etc., can solve the problems of low added value of products, bitter taste of enzymatic hydrolysis solution, etc., and achieve optimal enzymatic hydrolysis effect , reduce generation, increase added value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

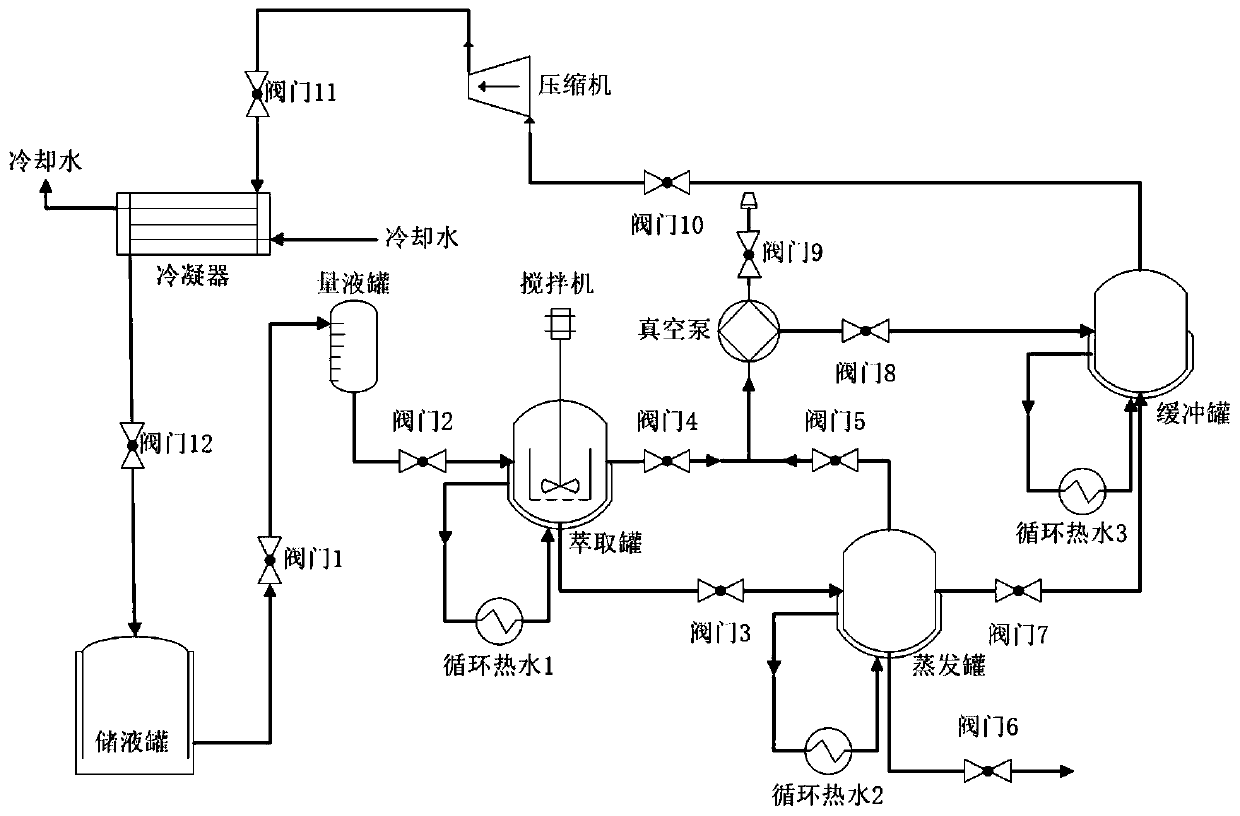

[0030] The extraction device in the present invention includes an extraction part and an extraction agent removal part, and its structure is as shown in the drawings of the description. figure 1 shown.

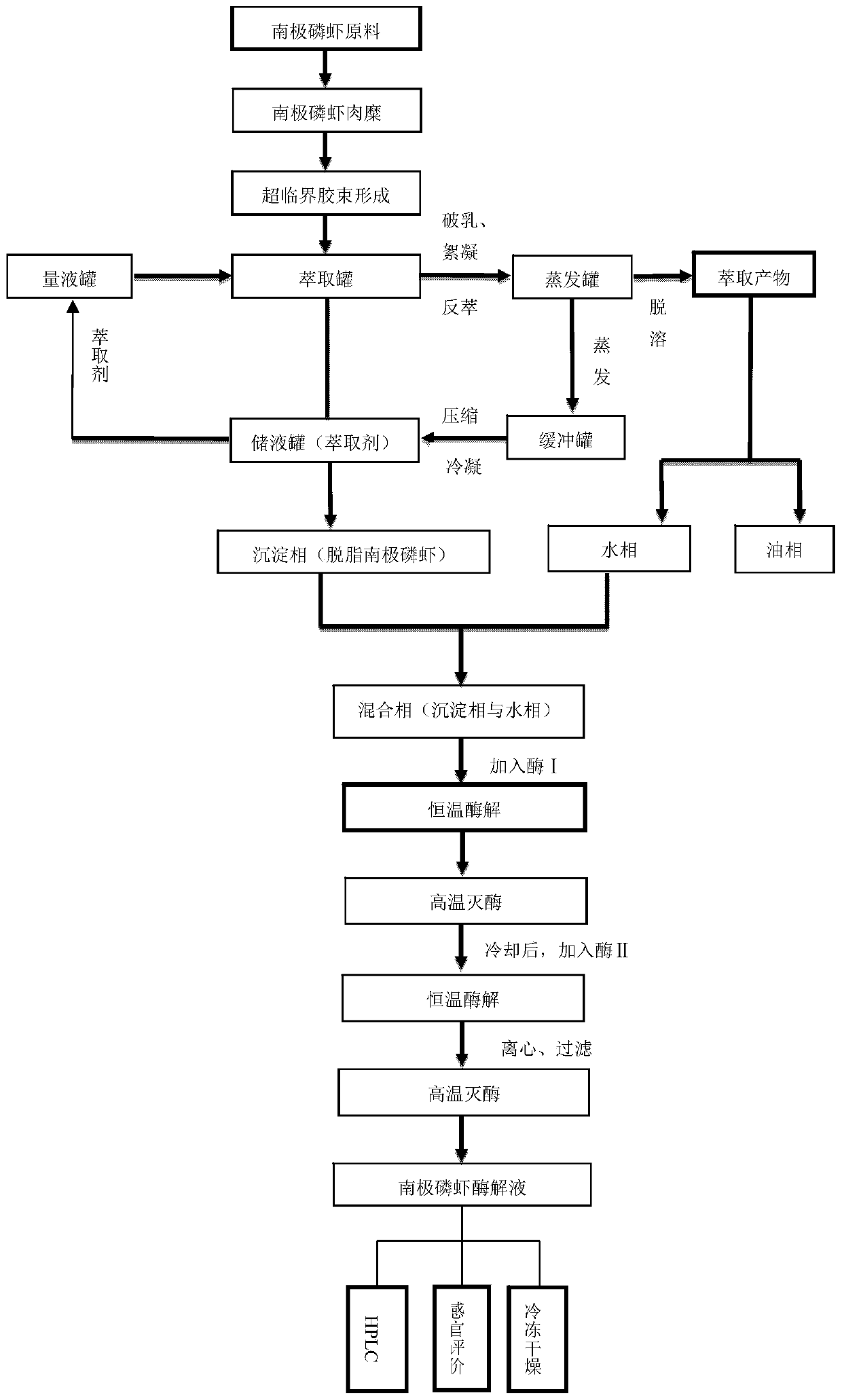

[0031] refer to figure 2 As shown, the subcritical extraction coupling step-by-step enzymatic hydrolysis technology is a preparation method for preparing Antarctic krill fresh and sweet enzymatic hydrolyzate, and the method includes the following steps.

[0032] (1) Pretreatment of raw materials: thaw the frozen Antarctic krill, stir and chop it into mince with a mixer, add 0.35% of the quality of Antarctic krill polyglycerol fatty acid ester and diacetyl tartaric acid mono-diglyceride mass ratio is 4: 5 mixed surfactants.

[0033] (2) Loading: put the pretreated Antarctic krill into a support covered with a nylon mesh sieve, seal and place it in the extraction tank of the extraction equipment, and use a nylon mesh sieve of 80 mesh.

[0034] (3) Extraction: start the extra...

Embodiment example 2

[0040] The extraction device in the present invention includes an extraction part and an extraction agent removal part, and its structure is as shown in the accompanying drawings figure 1 shown.

[0041] refer to figure 2 The subcritical extraction coupled step-by-step enzymatic hydrolysis technology is a method for preparing fresh and sweet enzymatic hydrolyzate of Antarctic krill. The method includes the following steps.

[0042] (1) Pretreatment of raw materials: thaw the frozen Antarctic krill, stir and chop it into mince with a blender, add 0.5% of the quality of Antarctic krill polyglycerol fatty acid ester and diacetyl tartaric acid mono-diglyceride with a mass ratio of 7: 9 mixed surfactants.

[0043] (2) Loading: put the pretreated Antarctic krill into a support covered with a nylon mesh sieve, seal and place it in the extraction tank of the extraction equipment, and use a 100-mesh nylon mesh.

[0044] (3) Extraction: start the extraction device to extract Antarct...

Embodiment 3

[0050] The extraction device in the present invention includes an extraction part and an extraction agent removal part, and its structure is as shown in the drawings of the description. figure 1 shown.

[0051] refer to figure 2 As shown, the subcritical extraction coupling step-by-step enzymatic hydrolysis technology is a preparation method for preparing Antarctic krill fresh and sweet enzymatic hydrolyzate, and the method includes the following steps.

[0052] (1) Pretreatment of raw materials: thaw the frozen Antarctic krill, stir and chop it into minced form with a blender, and add 0.35% by mass of Antarctic krill as surfactant polyglycerol fatty acid ester.

[0053] (2) Loading: put the pretreated Antarctic krill into a support covered with a nylon mesh sieve, seal and place it in the extraction tank of the extraction equipment, and use a 200-mesh nylon mesh.

[0054] (3) Extraction: start the extraction device to extract Antarctic krill, the extractant used is a compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com