High-temperature high-strength flexible zirconium oxide-silicon oxide fiber membrane as well as preparation method and application thereof

A technology of silica fiber and zirconia, which is applied in the direction of fiber chemical characteristics, rayon manufacturing, artificial filament of inorganic raw materials, etc., can solve the problem that the mechanical properties of fiber membranes cannot be guaranteed, high strength and high flexibility cannot be guaranteed, and zirconia cannot be inhibited Grain growth and other problems, to achieve the effect of simple and controllable preparation method, easy industrial production, fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for preparing high-temperature, high-strength flexible zirconia-silica fiber membrane includes the following preparation steps:

[0049] (1) Add 200g of PAZ to 1000g of absolute ethanol, stir until it is completely dissolved, add 25g of yttrium nitrate, stir until it is completely dissolved, add 2g of polyethylene oxide, dropwise add 60g of deionized water, heat to 45°C, stir until it is completely dissolved Then, 172g of ethyl orthosilicate was added and stirred for 8 hours to obtain a precursor spinning solution.

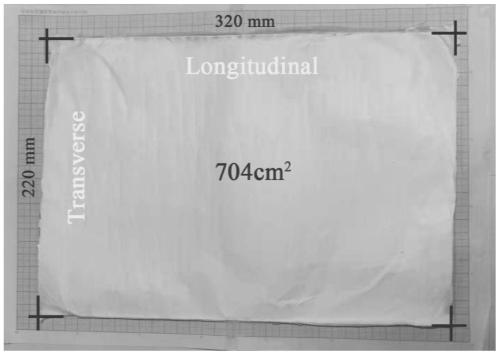

[0050] (2) Put the precursor spinning solution described in step (1) in the spinning parameters of humidity 45%, temperature 25°C, voltage 11KV, advancing speed 1.5ml / h, receiving distance 20cm, drum receiving speed 80r / min Electrospinning is carried out under the conditions to obtain the precursor fiber membrane; the actual photo is shown in the attached drawing figure 1 Shown.

[0051] (3) Heat the precursor fiber membrane spun in step (2) to obtain Zr...

Embodiment 2

[0054] As described in Example 1, the difference is:

[0055] In step (1), add 200g of PAZ to 667g of absolute ethanol, stir until it is completely dissolved, add 25g of yttrium nitrate, and stir until it is completely dissolved; add 2g of polyethylene oxide, dropwise add 60g of deionized water, heat to 45°C, and stir To completely dissolve, then add 172 g of ethyl orthosilicate and stir for 2 hours to obtain a precursor spinning solution.

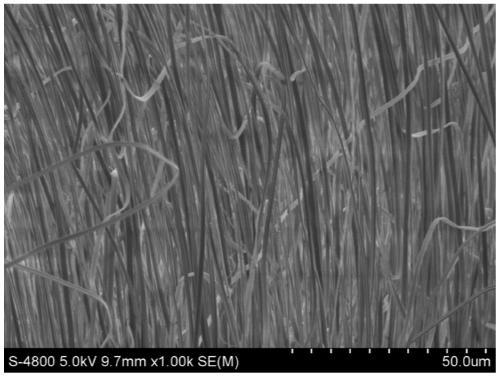

[0056] The obtained precursor spinning solution has good spinnability, the precursor fiber is longer than that in Example 1, and the fiber diameter is more uniform. ZrO 2 -SiO 2 The nanofiber membrane has a high degree of orientation, and the SEM picture of the ordered fiber membrane is as image 3 Shown.

Embodiment 3

[0058] As described in Example 1, the difference is:

[0059] In step (1), add 200g of PAZ to 1000g of absolute ethanol, stir until completely dissolved, add 2g of polyethylene oxide, add 60g of deionized water dropwise, heat to 45°C, stir until completely dissolved, then add 172g of ethyl orthosilicate Ester, stir for 8h to obtain the precursor spinning solution;

[0060] Without adding yttrium nitrate, ZrO 2 No phase change, SiO 2 Always amorphous, ZrO 2 -SiO 2 The nanofiber membrane has the same high strength and excellent flexibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com