Method for preparing alkane by photocatalysis of fatty acid decarboxylation

A fatty acid and photocatalytic technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of low conversion efficiency and harsh reaction conditions, and achieve low hydrogen consumption, good stability, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

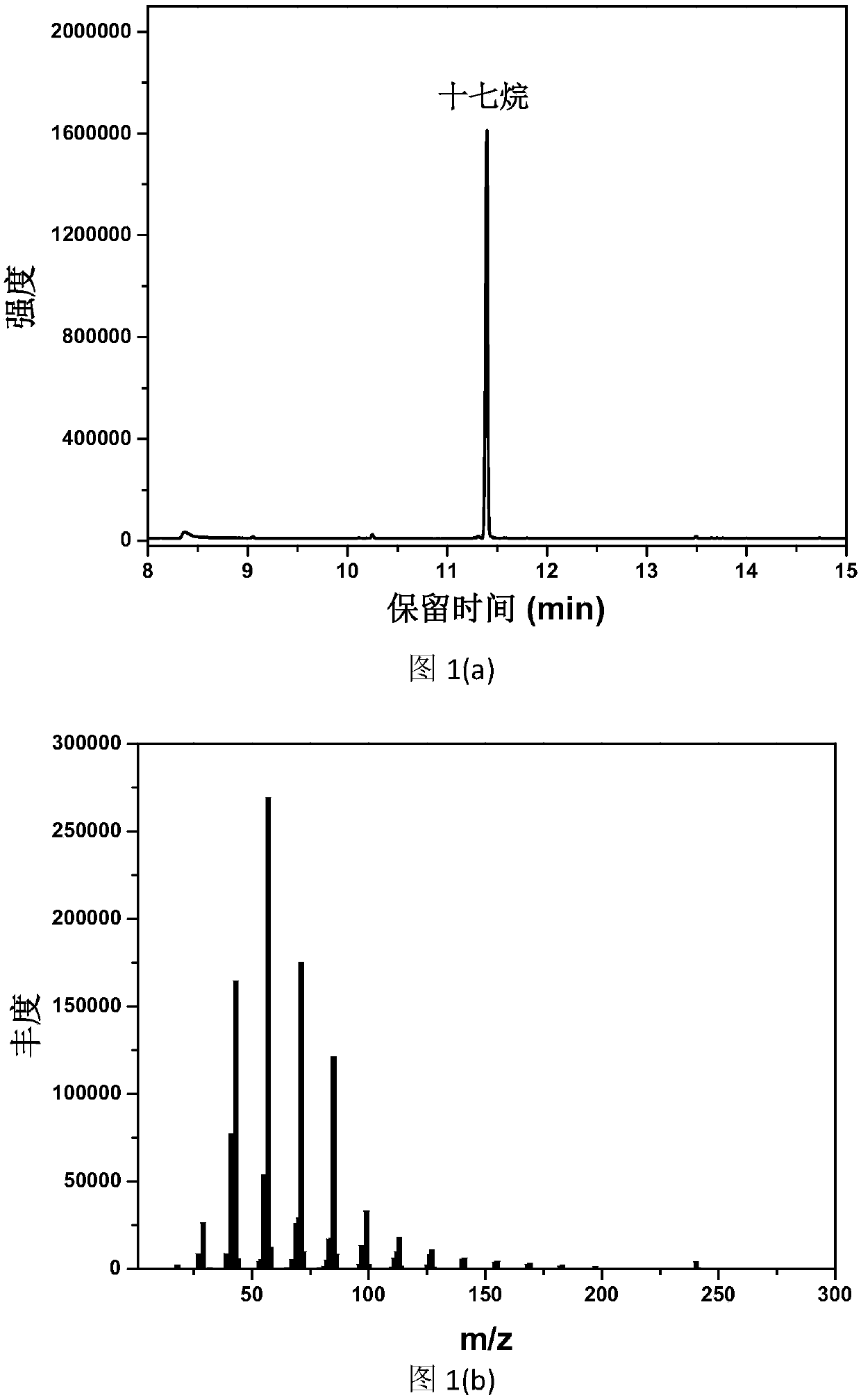

[0023] In a quartz reaction tube, add acetonitrile 1.5mL, octadecanoic acid 0.05mmol (concentration is 0.033mol / L) and Pt / TiO 2 (1wt%) 10mg, replace the atmosphere in the reaction tube with hydrogen (0.1MPa), seal, stir, and react at a temperature of 25°C. After reacting for 2.0h under the irradiation of LED (center wavelength 365nm, 18W), the product is detected by chromatography, and the mass spectrum of the product with standard spectrum Figure 1 As a result, the yield of heptadecane was 93%.

Embodiment 2

[0025] In a quartz reaction tube, add acetonitrile 1.5mL, octadecanoic acid 0.05mmol (concentration is 0.033mol / L) and Pd / TiO 2 (1wt%) 10mg, replace the atmosphere in the reaction tube with hydrogen (0.1MPa), seal, stir, and react at a temperature of 25°C. After reacting for 2.0h under the irradiation of LED (center wavelength 365nm, 18W), the product is detected by chromatography, and the mass spectrum of the product with standard spectrum Figure 1 As a result, the yield of heptadecane was 81%.

Embodiment 3

[0027] In a quartz reaction tube, add acetonitrile 1.5mL, octadecanoic acid 0.05mmol (concentration is 0.033mol / L) and Au / TiO 2 (1wt%) 10mg, replace the atmosphere in the reaction tube with hydrogen (0.1MPa), seal, stir, and react at a temperature of 25°C. After reacting for 2.0h under the irradiation of LED (center wavelength 365nm, 18W), the product is detected by chromatography, and the mass spectrum of the product with standard spectrum Figure 1 As a result, the yield of heptadecane was 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com