Monoepoxy material and preparation method thereof

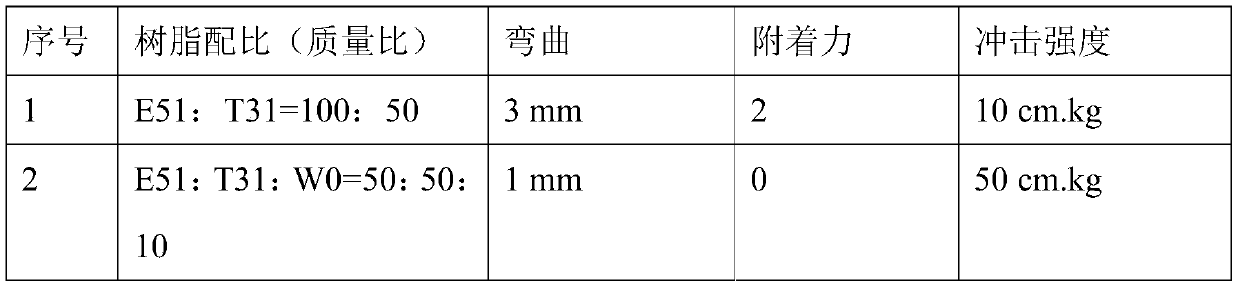

A single epoxy, CH2CH3 technology, used in the chemical industry, can solve the problems of no choice of toughening agent, oily (water-based) epoxy resin is brittle, etc., to achieve good flexibility and adhesion, large room for adjustment, stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

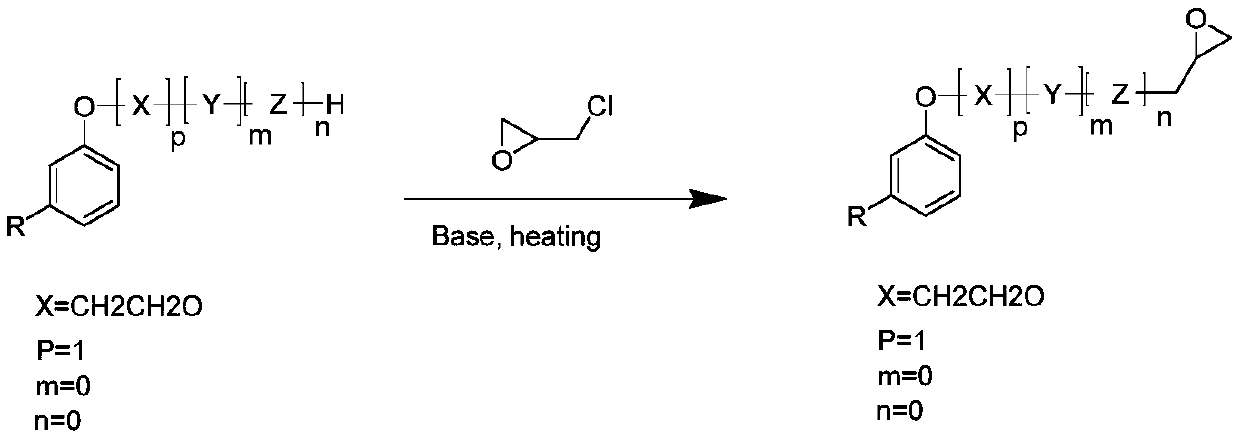

Method used

Image

Examples

Embodiment 1

[0020]

[0021] A preparation method of a single epoxy material: Add cardanol polyoxyethylene ether (n=0) (344g, 1mol) into a four-necked bottle, add an appropriate amount of solvent to dilute, and then add (92.5g, 1mol) epichlorohydrin , heated to 50°C, then slowly added 35g of boron trifluoride diethyl ether dropwise, stirred at this temperature for 5 hours, then added dropwise a 50% aqueous solution of sodium hydroxide (1eq) at this temperature, and controlled the temperature during the dropwise addition Do not exceed 120°C. After the dropwise addition, keep the temperature at 50-120°C for 10 hours. After the reaction is detected by GC, wash with water 2-3 times, each time with 250 mL of water, and then distill the organic phase under reduced pressure at 120°C. When the solid content > 99.5%, the vacuum distillation was stopped, and the indicators were detected, and a light yellow liquid WO (398g, 99.5%) was obtained after meeting the requirements. Epoxy value: 0.2499mol...

Embodiment 2

[0028]

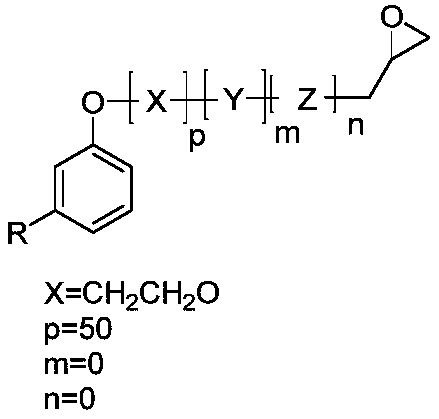

[0029] A kind of preparation method of single epoxy material: cardanol polyoxyethylene ether (n=50) (2104g, 1mol) is added in the four-necked bottle, adds toluene (20L) to dilute, then adds epichlorohydrin (462.6, 5mol ), heated to 100°C, added 2.1g of boron trifluoride diethyl ether at this temperature and then stirred for 5 hours, then slowly added NaOH aqueous solution (160g, 50% aqueous solution) dropwise, and the temperature should not exceed 120 ℃, keep the temperature at 80-110℃ for 10 hours after the dropwise addition, wash with water for 2-3 times after GC detection, then distill the organic phase under reduced pressure at 50-120℃, and detect when the solid content is >99.5% Stop the distillation under reduced pressure, and check the indicators. After meeting the requirements, the off-white solid W1 is obtained, 2140g (Y=99%). Epoxy value: 0.0468mol / 100g

Embodiment 3

[0031]

[0032] A kind of preparation method of single epoxy material: cardanol polyoxyethylene ether (4444g, 1mol) is added in the four-necked bottle, adds xylene (40L), then adds epichlorohydrin (925g, 10mol), is heated to 60 ℃, add boron trifluoride diethyl ether 50g at this temperature and then stir for 5 hours, add KOH aqueous solution (224g, 50% aqueous solution) dropwise at this temperature, and pay attention to controlling the temperature not exceeding 120°C during the dropping process. Keep the temperature at 50°C for 10 hours, wash with water for 2-3 times after GC detection, then distill the organic phase under reduced pressure at 50-120°C, stop the reduced-pressure distillation when the solid content is >99.5%, and check the indicators , after meeting the requirements, the off-white solid W2 was discharged, 4720g, (Y=98.3), epoxy value: 0.022mol / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com