Preparation method and application of jasmine flower residue active polysaccharide

A technology of jasmine residue and active polysaccharides, which is applied in the direction of organic active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, can solve the problems of single extraction solvent, poor repeatability, and molecular weight dispersion of polysaccharides, and achieve high-efficiency separation and purification. The effect of avoiding structural changes and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

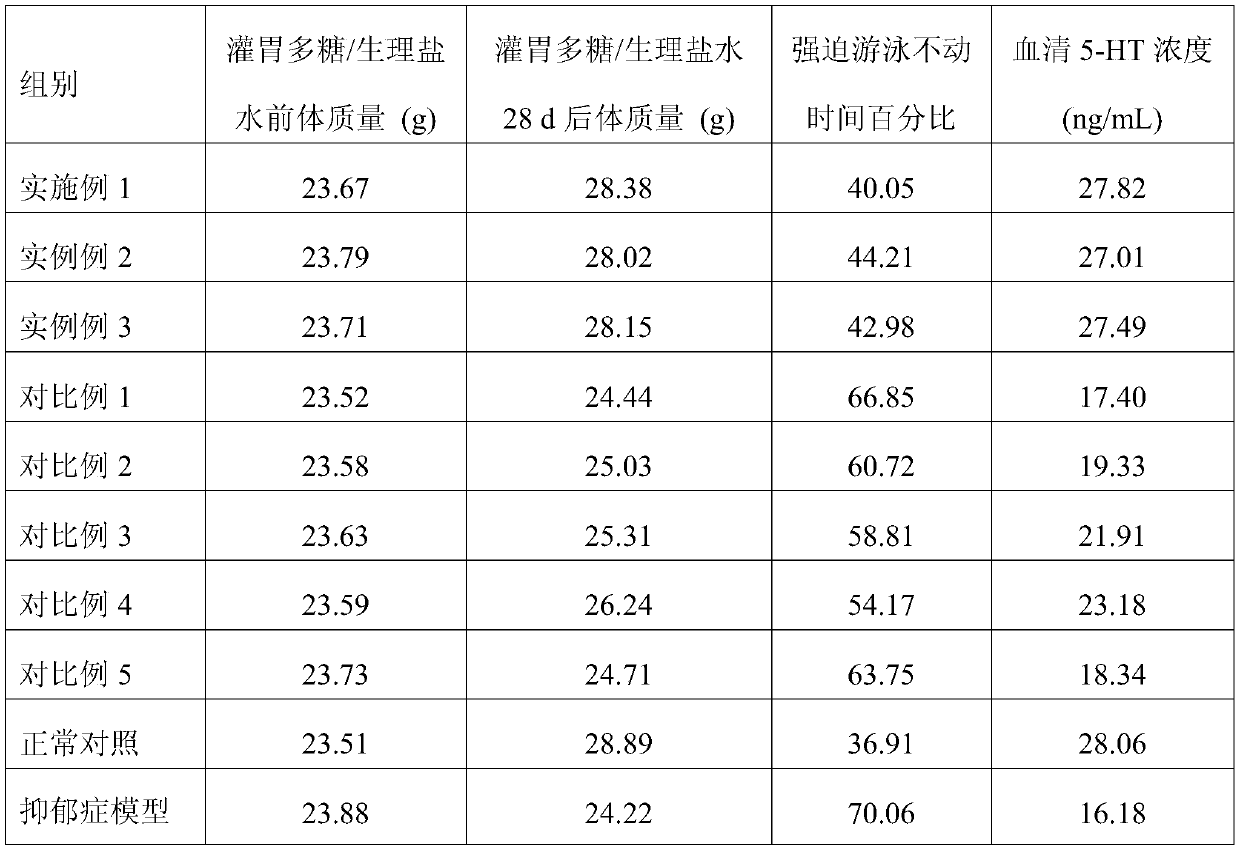

Examples

Embodiment 1

[0033] The preparation method of jasmine slag active polysaccharide comprises the steps:

[0034] (1) Jasmine dregs pretreatment: Dry jasmine dregs at 55°C to constant weight, crush and pass through a 40-mesh sieve to obtain jasmine dregs powder; add jasmine dregs powder and absolute ethanol according to the solid-to-liquid ratio of 1mg: 20mL, and ultrasonically After shaking for 2.5 hours, filter to take the filter residue, and dry it at 55°C to constant weight, which is the defatted jasmine residue powder;

[0035] (2) Sample preparation of expansive jasmine dregs: put defatted jasmine dregs powder into a polyethylene plastic bag, put it into the equipment, treat it at 25°C and ultra-high pressure 400MPa for 2 minutes, and then release the pressure instantly, so that the raw material of jasmine dregs becomes expanded. Sexual jasmine residue sample;

[0036] (3) Preparation of the total extract of jasmine slag: weigh a certain amount of pretreated jasmine slag powder, add wa...

Embodiment 2

[0043] The preparation method of jasmine slag active polysaccharide comprises the steps:

[0044] (1) Jasmine slag pretreatment: drying jasmine slag to constant weight, crushing and sieving to obtain jasmine slag powder; mixing jasmine slag powder with absolute ethanol, the solid-to-liquid ratio 1:25mg / mL, after ultrasonic oscillation for 3 hours, filter to take the filter residue, and dry to constant weight, which is the defatted jasmine residue powder;

[0045] (2) Preparation of expansive jasmine dregs powder: put defatted jasmine dregs powder into a polyethylene plastic bag, then treat at 20°C and ultra-high pressure of 450 MPa for 1 min, and then release the pressure instantly, so that the jasmine dregs powder becomes expandable jasmine dregs powder ;

[0046] (3) Preparation of the total extract of jasmine dregs: add water to the expandable jasmine dregs powder, the solid-to-liquid ratio of the expandable jasmine dregs powder to water is 1:25 mg / mL; then pack into a pol...

Embodiment 3

[0053] The preparation method of jasmine slag active polysaccharide comprises the steps:

[0054] (1) Jasmine slag pretreatment: drying jasmine slag to constant weight, crushing and sieving to obtain jasmine slag powder; mixing jasmine slag powder with absolute ethanol, the solid-to-liquid ratio 1:25mg / mL, after ultrasonic oscillation for 2 hours, filter to take the filter residue, and dry to constant weight, which is the degreased jasmine residue powder;

[0055] (2) Preparation of expansive jasmine dregs powder: put defatted jasmine dregs powder into a polyethylene plastic bag, then treat at 27°C under ultra-high pressure 350 MPa for 3 minutes, and then release the pressure instantly, so that the jasmine dregs powder becomes expandable jasmine dregs powder;

[0056] (3) Preparation of the total extract of jasmine dregs: add water to the expandable jasmine dregs powder, the solid-to-liquid ratio of the expandable jasmine dregs powder to water is 1:25 mg / mL; then pack into a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com