High-elasticity rubber ring rubber material for textile machinery and preparation method thereof

A technology of textile machinery and high elasticity, which is applied in the field of high elasticity apron rubber materials for textile machinery and its preparation, which can solve the limitations of application range, poor self-adhesion and mutual adhesion of oil and chemical reagents, difficult polar polymer blending, etc. problem, to achieve the effect of reducing raw material cost, good holding force, drafting force, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

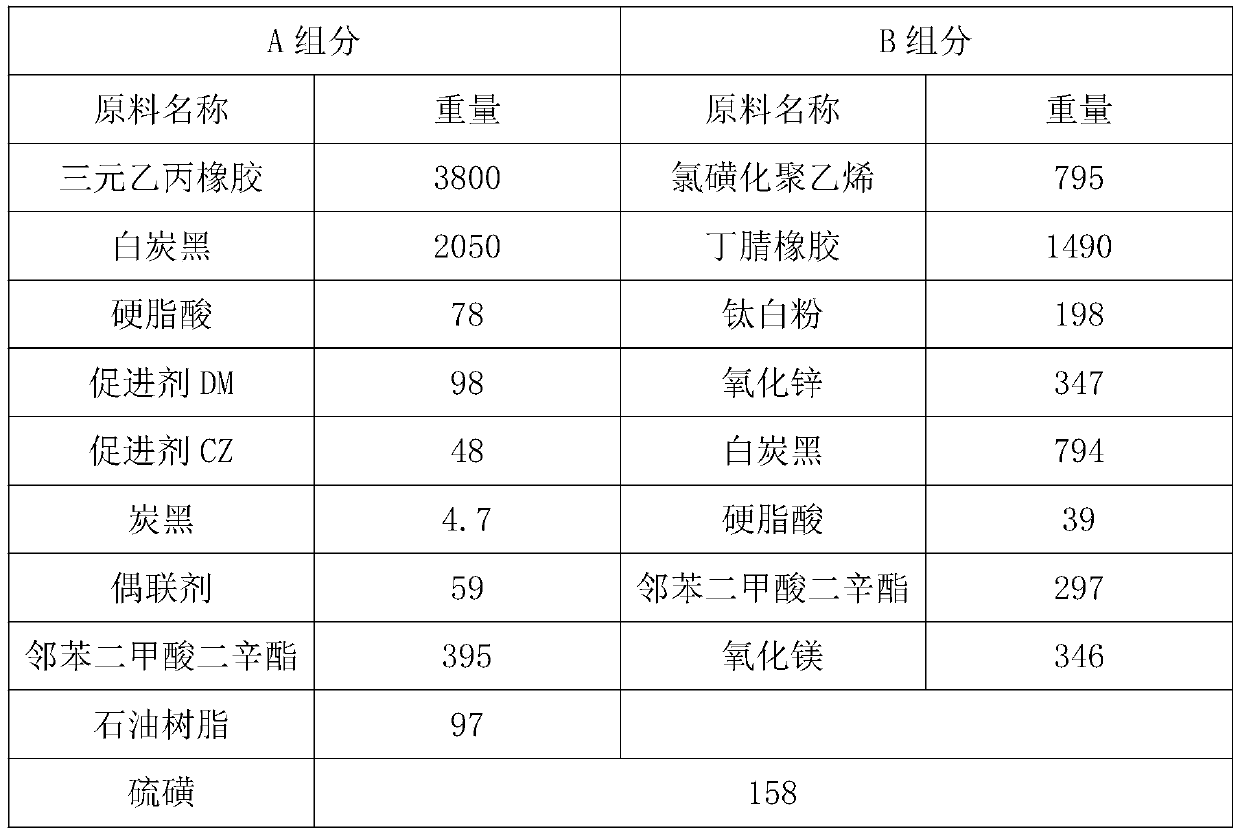

[0033] A high-elastic apron rubber compound for textile machinery, which is prepared by mixing components A and B with a vulcanizing agent. The specific formula of each component is as follows: unit: g

[0034]

[0035] The method for using the above-mentioned raw materials to process the high-elastic apron rubber compound for textile machinery comprises the following steps:

[0036] (1) First weigh the raw materials of component A, put the weighed raw materials of component A into the internal mixer and mix and stir for 2 minutes at 97 ° C, then pour the mixed rubber into the open mixer, and mix at 68 Pack and knead at ℃, and release the film to obtain A soft film; then weigh the raw materials of component B, add the weighed component B raw materials into the internal mixer, mix and stir for 3 minutes at 93 ℃, and then mix well Pour the rubber material into the open mill, pack and knead at 62°C, and release the film to obtain B soft film;

[0037] (2) Combine the soft fil...

Embodiment 2

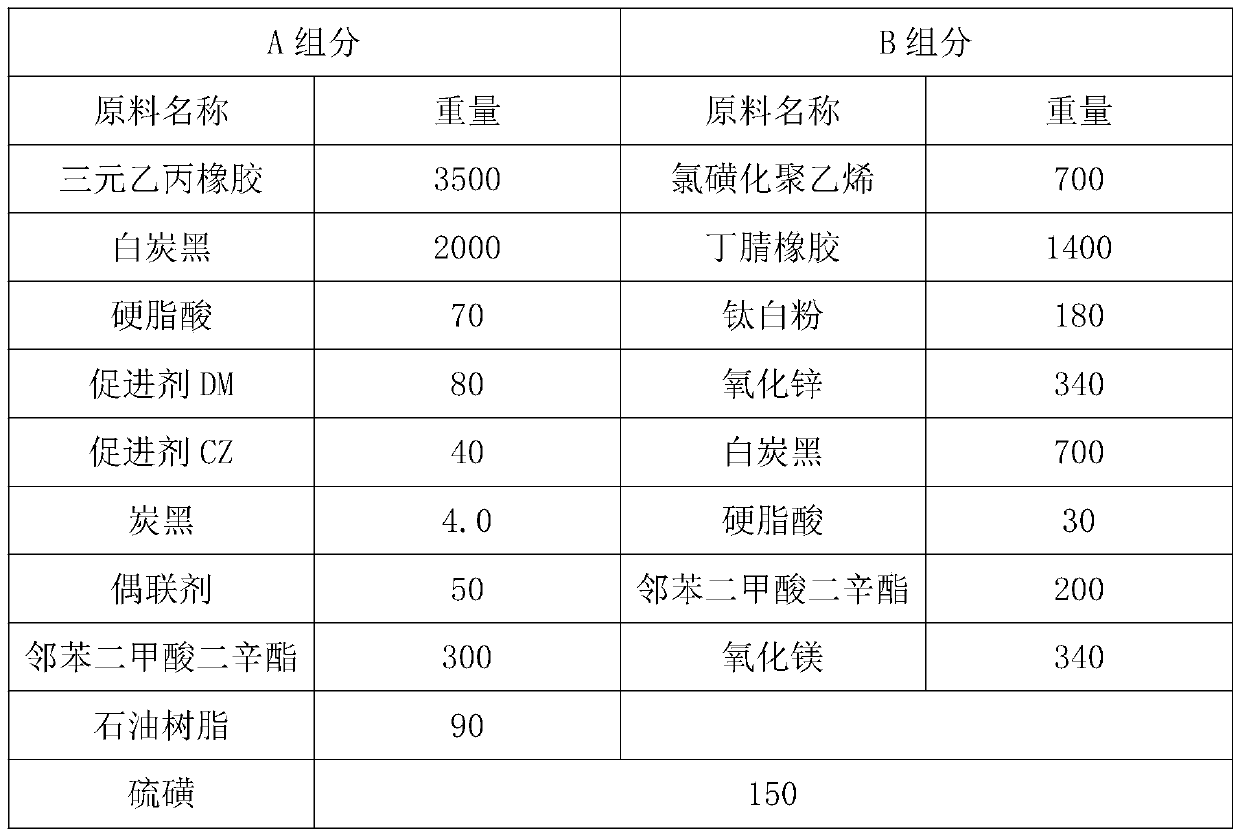

[0041] A high-elastic apron rubber compound for textile machinery, which is prepared by mixing components A and B with a vulcanizing agent. The specific formula of each component is as follows: unit: g

[0042]

[0043] The preparation method is the same as in Example 1.

Embodiment 3

[0045] A high-elastic apron rubber material for textile machinery, which is prepared by mixing components A and B with a vulcanizing agent. The specific formula of each component is as follows: unit: g

[0046]

[0047]

[0048] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com