Preparation method of functional peanut oil

A peanut oil and functional technology, applied in the direction of fat oil/fat refining, fat production, fat oil/fat production, etc., can solve the problems of ignoring the effect of natural anti-oxidation and antibacterial substances, deepening of color, destruction of protein nutrients, etc., to achieve improved Antioxidant performance and nutritional composition, reduction of trans fatty acid content, effect of improvement in antioxidant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

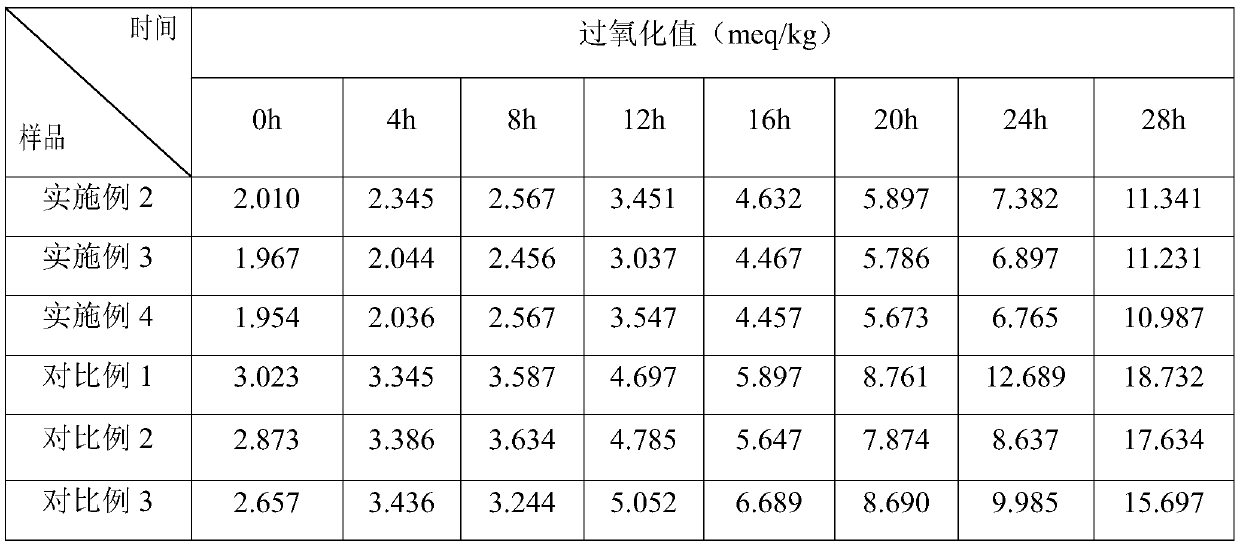

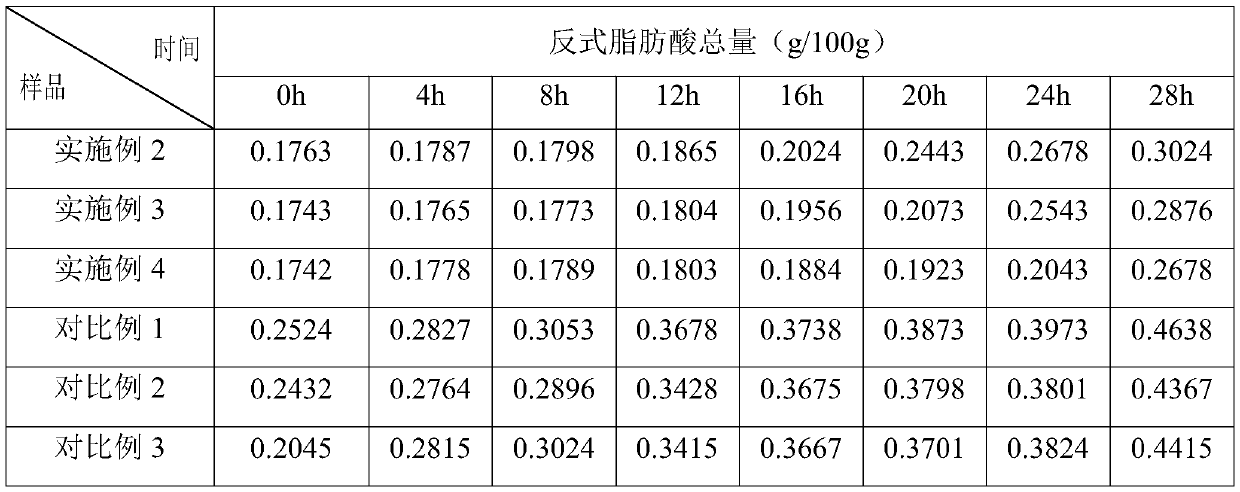

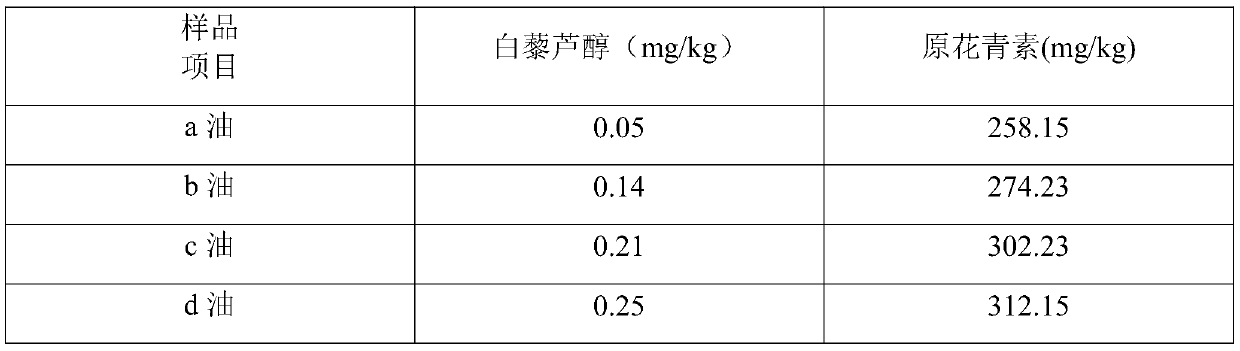

Examples

Embodiment 1

[0030] Screening of cooking time during preparation of functional peanut oil:

[0031] (1) Pre-treatment of oil: take fresh peanuts and put them in boiling water for 0h, 0.5h, 1h, 1.5h, 2h, 3h respectively, then take out the peanuts and place them in a dry place at 60-70°C (water content less than 5%), then Hulled peanut seeds;

[0032] (2) Pulverization: after peanut seeds are pulverized into a powder with a particle size of 100-120 mesh, soaked in a mixed emulsion of 5 times the weight, soaked for 2 hours under the synergistic effect of ultrasonic and microwave, and then centrifuged to obtain supernatant oil A and an emulsified layer; , the mixed emulsion is obtained by dispersing sucrose palmitate, garlic oil, and cysteine hydrochloride in aqueous ethanol (V / V=1:10) and homogenizing, and the mass percentage of sucrose palmitate in the mixed emulsion 0.1wt%, the mass percentage of garlic oil is 0.1wt%, and the mass percentage of cysteine hydrochloride is 0.01wt%; wherei...

Embodiment 2

[0047] (1) Pre-treatment of oil: take fresh peanuts and cook them in boiling water for 2 hours, then take out the peanuts and dry them at 60-70°C (water content is less than 5%), and then shell them to obtain peanut seeds;

[0048] (2) Pulverization: after peanut seeds are pulverized into a powder with a particle size of 100-120 mesh, soaked in a mixed emulsion of 10 times the weight, soaked for 1 hour under the synergistic effect of ultrasonic and microwave, and then centrifuged to obtain supernatant oil A and an emulsified layer; , the mixed emulsion is obtained by dispersing sucrose palmitate, garlic oil, and cysteine hydrochloride in aqueous ethanol (V / V=1:10) and homogenizing, and the mass percentage of sucrose palmitate in the mixed emulsion 0.1wt%, the mass percentage of garlic oil is 0.1wt%, and the mass percentage of cysteine hydrochloride is 0.01wt%; wherein, the ultrasonic frequency is 35KHz, the power is 400-600W, and the microwave power is 200- 300W;

[0049]...

Embodiment 3

[0053] The preparation method of functional peanut oil:

[0054] (1) Pre-treatment of oil: take fresh peanuts and cook them in boiling water for 2 hours, then take out the peanuts and dry them at 60-70°C (water content is less than 5%), and then shell them to obtain peanut seeds;

[0055] (2) Pulverization: Soak the peanut seeds in a mixed emulsion of 7.5 times the weight after being pulverized, soak for 1.5 hours under the synergistic effect of ultrasonic and microwave, and then centrifuge to obtain supernatant oil A and an emulsified layer; wherein, the mixed emulsion is made of palmitic acid sucrose Esters, garlic oil, and cysteine hydrochloride are dispersed in ethanol aqueous solution (V / V=1:10) and obtained homogeneously, and the mass percentages of sucrose palmitate and garlic oil in the mixed emulsion are 0.1wt%, The mass percentage of cysteine hydrochloride is 0.03wt%; the ultrasonic frequency is 35KHz, the power is 400-600W, and the microwave power is 200-300W; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com