High-strength heat-resistant self-repairing concrete and preparation method thereof

A concrete and self-repairing technology, applied in the field of concrete, can solve problems such as failure to achieve the best use state, high water content of tuff raw ore, and ineffective use of stone powder, etc., to achieve improved adhesion, excellent mechanical properties, and crack prevention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

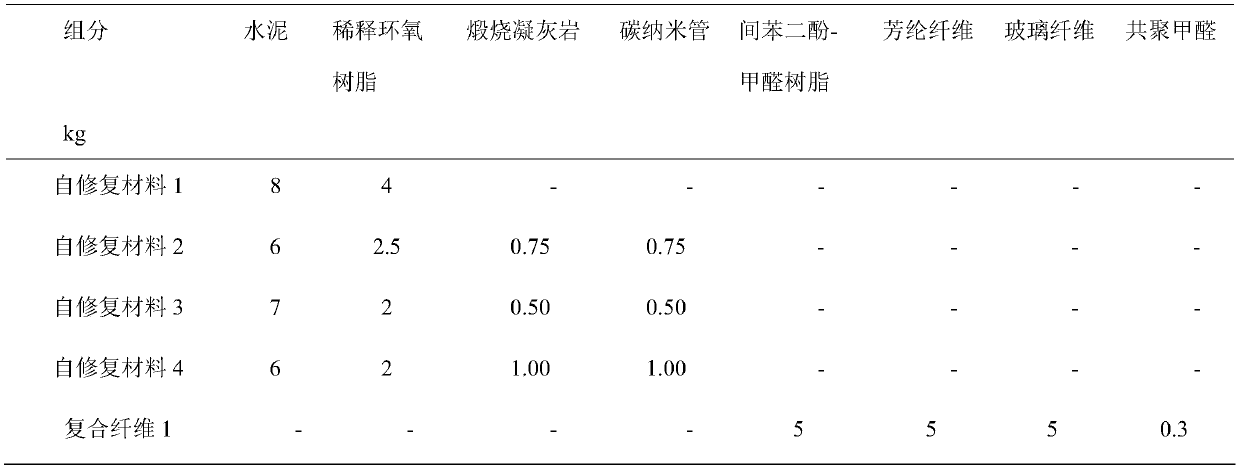

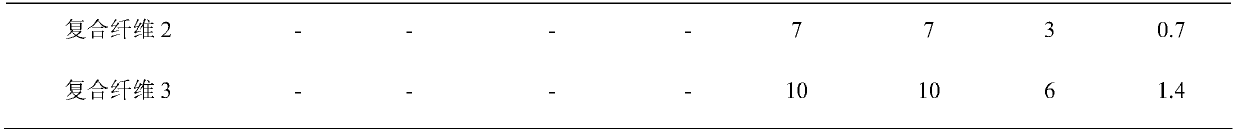

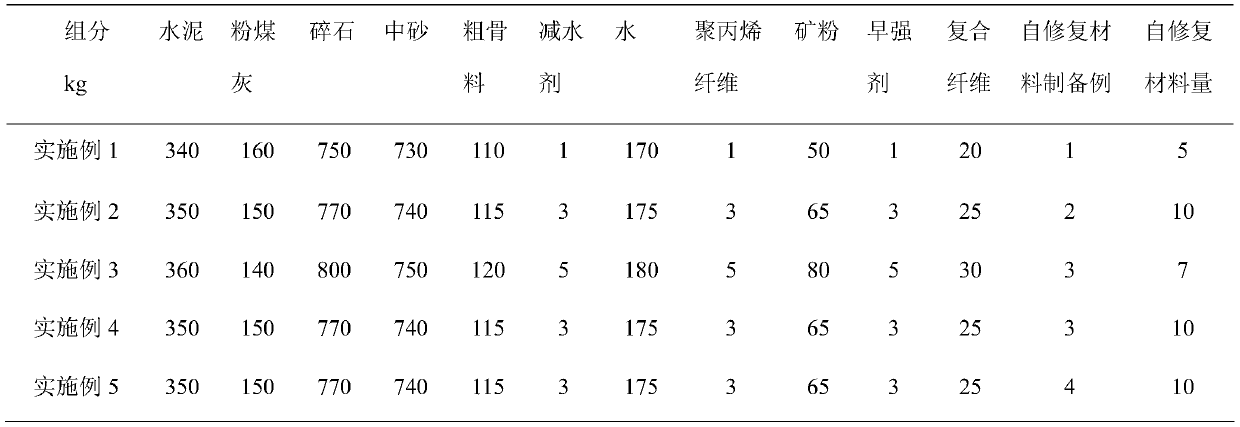

Method used

Image

Examples

Embodiment 1

[0055] S1: The cement is P.O42.5 Portland cement, the fly ash is low calcium grade II, the fineness (45μm square hole sieve residue) is 8%, the water demand ratio is 95%, and the loss on ignition is 2 %, the crushed stone is 5-20mm continuous graded crushed stone, the fineness modulus of the medium sand is 2.3, the mud content is 2%, the mud content is 0.45%, the mineral powder is S95 grade mineral powder, and the activity index is 28 days The fluidity ratio is 95%, the coarse aggregate is mixed with hollow glass microspheres and ceramsite with a mass ratio of 1:1.2, the particle size of hollow glass microspheres is 10mm, and the particle size of ceramsite is 5mm .

[0056] S2: According to the ratio of raw materials in Table 2, fully mix the cement, fly ash, crushed stone, medium sand, mineral powder, and coarse aggregate in S1 to prepare premix A;

[0057] S3: According to the ratio of raw materials in Table 2, add aliphatic (hydroxyl) sulfonate high-efficiency water reduce...

Embodiment 2

[0058] The difference between embodiment 2 and embodiment 1 is: fly ash is low calcium II grade, fineness (45 μ m square hole sieve residue) is 11%, water demand ratio is 97%, loss on ignition is 3%, medium The fineness modulus of the sand is 2.7, the mud content is 2.3%, and the mud content is 0.55%. The coarse aggregate is made of hollow glass microspheres and ceramsite with a mass ratio of 1:1.4. The hollow glass microspheres The particle size is 13mm, and the particle size of ceramsite is 8mm. Add polycarboxylate high-efficiency water reducer and self-healing material 2 to S3, add premix A and mix thoroughly for 100 minutes.

Embodiment 3

[0059] The difference between embodiment 3 and embodiment 1 is: fly ash is low calcium II grade, fineness (45 μ m square hole sieve residue) is 13%, water demand ratio is 98%, loss on ignition is 4.5%, middle The fineness modulus of the sand is 3.0, the mud content is 2.6%, and the mud content is 0.65%. The coarse aggregate is made of hollow glass microspheres and ceramsite with a mass ratio of 1:1.5. The hollow glass microspheres The particle size is 15mm, and the particle size of ceramsite is 10mm. Add naphthalene-based water reducer and self-healing material 3 to S3, add premix A and mix thoroughly for 120 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com