Method for preparing silicon nitride ceramic with high strength, high toughness and high thermal conductivity

A technology for silicon nitride ceramics and ceramic green bodies, which is applied to high thermal conductivity silicon nitride ceramics to prepare high strength and high toughness fields. Silicon sintering, the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 28.09g of silicon powder (particle size 1μm) and 3.22g of composite sintering aids (MgO and Sm 2 o 3 The molar ratio is 5:2) powder as raw material, absolute ethanol as solvent, placed in a ball mill tank for ball milling for 2h (the particle size of the ground silicon powder is 0.5 μm), and then the dried and sieved mixture Put it in the mold, dry press molding at 30MPa, carry out cold isostatic pressing of the obtained green body, the pressure is 300MPa, put the final obtained ceramic green body in a carbon tube furnace, and heat up at a rate of 10°C / min in a vacuum environment After heating up to 900°C for 2 hours, nitrogen was used as a protective atmosphere, and the temperature was raised to 1400°C for 6 hours at a rate of 10°C / min for nitriding to obtain a silicon nitride ceramic body with a nitriding rate of 97.55%. The density is 72%. The pressure sintering process is to raise the temperature to 1900°C under the condition of a nitrogen atmosphere with a pressu...

Embodiment 2

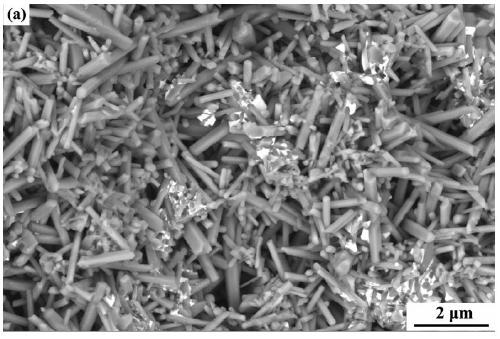

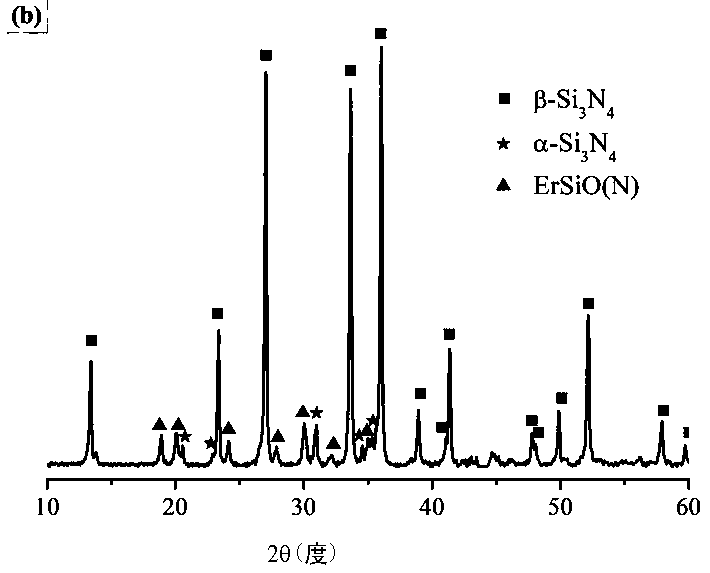

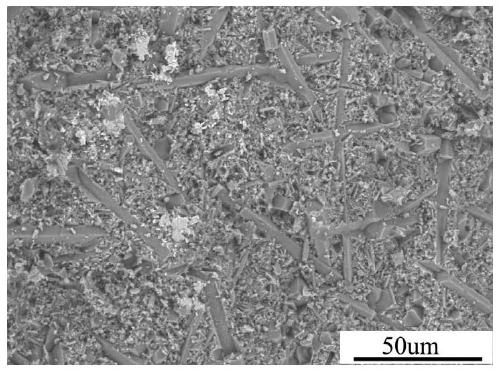

[0045] 27.96g of silicon powder (particle size 1μm) and 3.45g of composite sintering aids (MgO and Er 2 o 3 The molar ratio is 5:2) powder as raw material, absolute ethanol as solvent, placed in a ball mill tank for ball milling for 2h (the particle size of the ground silicon powder is 0.4μm), and then the dried and sieved mixture Put it in the mold, dry press molding at 30MPa, carry out cold isostatic pressing of the obtained green body, the pressure is 300MPa, put the final obtained ceramic green body in a carbon tube furnace, and heat up at a rate of 10°C / min in a vacuum environment After heating up to 900°C for 2 hours, nitrogen was used as a protective atmosphere, and the temperature was raised to 1450°C for 4 hours at a rate of 10°C / min for nitriding to obtain a silicon nitride ceramic body with a nitriding rate of 97.31%. The density is 72%. The pressure sintering process is to raise the temperature to 1900°C under the condition of a nitrogen atmosphere with a pressur...

Embodiment 3

[0048] 28.68g of silicon powder (particle size 15μm) and 2.25g of composite sintering aids (MgO, Y 2 o 3 and CeO 2 The molar ratio is 3.4:0.9:1.6) powder as raw material, absolute ethanol as solvent, placed in a ball mill tank for ball milling for 10h (the particle size of the ground silicon powder is 0.93 μm), and then the dried and sieved The mixture is placed in a mold, and dry-pressed at 30 MPa, and the resulting green body is subjected to cold isostatic pressing at a pressure of 300 MPa. The final obtained ceramic green body is placed in a carbon tube furnace, and the temperature of 10 ° C / min is increased in a vacuum environment. After the heating rate was raised to 600°C for 4 hours, nitrogen was used as the protective atmosphere, and the temperature was raised to 1420°C for 6 hours at a heating rate of 10°C / min for nitriding to obtain a silicon nitride ceramic body with a nitriding rate of 97.38%. The relative density of the body is 71.94%. The pressure sintering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com