A kind of ultra-fast photon curing conductive adhesive and preparation method thereof

A technology of photonic curing and conductive adhesives, applied in the direction of conductive adhesives, modified epoxy resin adhesives, etc., can solve the problems of short operation time, long operation time, generally more than 2 hours, etc., to achieve fast curing speed, The effect of high practical value and low volume resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

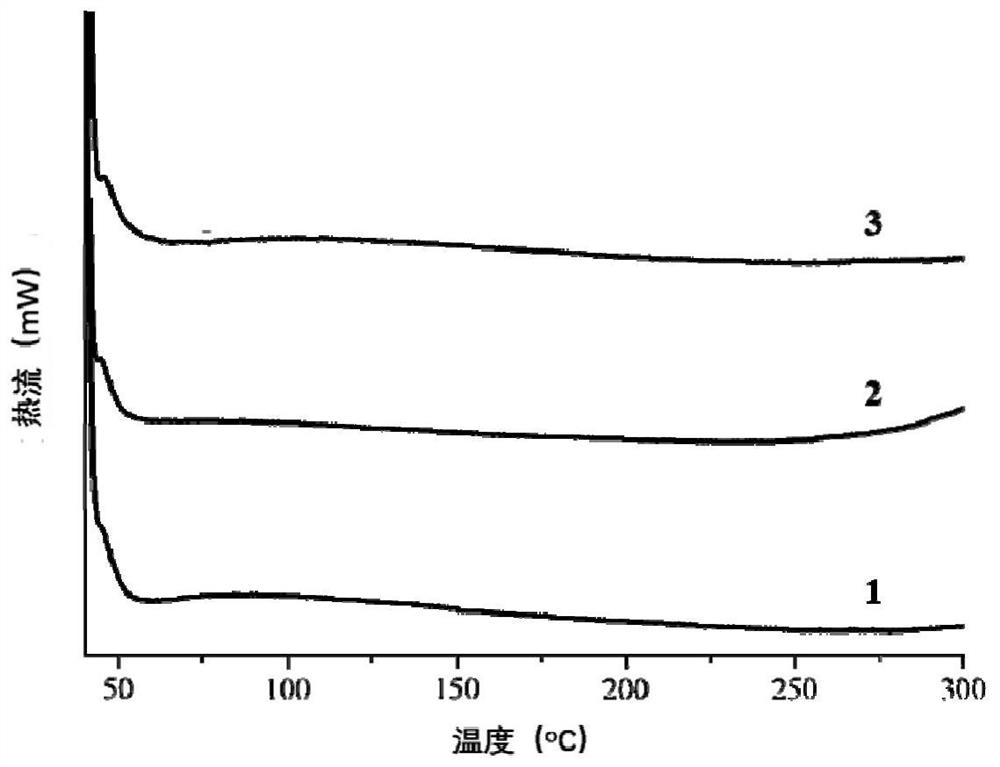

Image

Examples

preparation example Construction

[0060] A second aspect of the present invention provides a method for preparing an ultra-fast photon-cured conductive adhesive, comprising the following steps:

[0061] (1) Preparation of conductive adhesive: Fully stir and disperse vinyl ester resin, diluent, coupling agent, photoinitiator, thermal initiator, thixotropic agent, anti-impact agent, and silver powder, then grind and defoam, that is obtain the conductive adhesive;

[0062] (2) Curing of the conductive adhesive: the conductive adhesive prepared in step (1) was cured by using a photonic sintering system.

[0063] The inventors of the present application found that by introducing functional double bond groups into the polymer chain of the conductive adhesive body resin, under the conditions of the presence of multifunctional reactive diluents and silver powder, the use of photon energy helps the conductive adhesive to achieve super With the effect of rapid curing, a conductive adhesive with low resistivity and high...

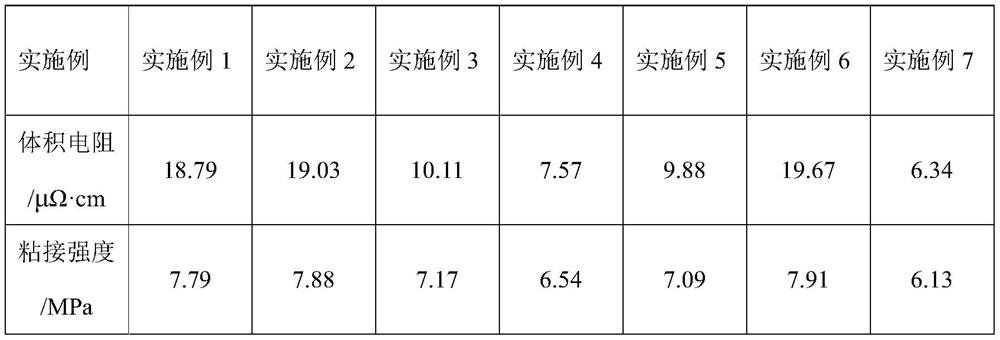

Embodiment 1

[0067] Embodiment 1 provides an ultra-fast photon-curable conductive adhesive. In parts by weight, the preparation raw materials are 15 parts of vinyl ester resin, 10 parts of diluent, 0.5 part of coupling agent, 2 parts of photoinitiator, and 0 parts of thermal initiator. parts, 0.5 parts of thixotropic agent, 2 parts of anti-impact agent, and 70 parts of silver powder.

[0068] The vinyl ester resin is novolak epoxy vinyl ester resin, which can be obtained commercially, the manufacturer is Ripoxy, and the brand is 630.

[0069] The diluent is hydroxyethyl methacrylate (CAS: 868-77-9).

[0070] The coupling agent is epoxy silane KH-560 (CAS: 2530-83-8).

[0071] The photoinitiator is a triaryl iodonium salt, commercially available, the manufacturer is Bluesil PI, and the brand is 2074.

[0072] The thixotropic agent is polyamide wax, which can be obtained commercially, the manufacturer is Disparlon, and the brand is 6500.

[0073] The anti-impact agent is 1,3-propanediol b...

Embodiment 2

[0079] Embodiment 2 provides an ultra-fast photon-curable conductive adhesive. In parts by weight, the preparation raw materials are 20 parts of vinyl ester resin, 5 parts of diluent, 0.5 part of coupling agent, 0 part of photoinitiator, and 2 parts of thermal initiator. parts, 0.5 parts of thixotropic agent, 2 parts of anti-impact agent, and 70 parts of silver powder.

[0080] The vinyl ester resin is a polyurethane-modified epoxy vinyl ester resin, which is commercially available, and the manufacturer is Atlac, and the brand is 580.

[0081] The diluent is 1,6-hexanediol diacrylate (CAS: 13048-33-4).

[0082] The coupling agent is aminosilane KH-550 (CAS: 919-30-2).

[0083] The thermal initiator is a peroxyketal, which can be obtained commercially, the manufacturer is Trigonox, and the brand is 122-C80.

[0084] The thixotropic agent is silicon dioxide, which can be obtained commercially, the manufacturer is Aerosil, and the brand is R202.

[0085] The anti-impact agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com