Preparation method of carboxyl nitrile rubber composite film for electromagnetic shielding

A technology of carboxylated nitrile rubber and electromagnetic shielding, which is applied in the field of preparation of carboxylated nitrile rubber composite film for electromagnetic shielding, can solve the problems of low conductivity and poor shielding effect, achieve excellent performance, improve conductivity and reduce resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

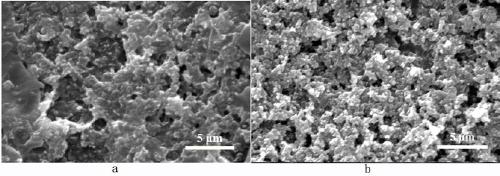

Image

Examples

Embodiment 1

[0022] A kind of preparation method of carboxylated nitrile rubber composite film for electromagnetic shielding of the present embodiment, the steps are as follows:

[0023] (1) Add 0.5 g of nano-carbon black to 9.5 g of 80% polyethylenimine cross-linking agent aqueous solution, and stir at 90° C. for 2 hours to obtain a mixed solution of nano-carbon black / polyethylenimine cross-linking agent;

[0024] (2) Take 0.5 g of the nano-carbon black / polyethylenimine crosslinking agent mixed solution prepared in step (1) and add it to 10 g of nitrile rubber emulsion, and stir at 80°C for 2 hours to obtain nano-carbon black / polyethylenimine Pyridine crosslinking agent / carboxylated nitrile latex blended solution, after standing for defoaming, polymer casting solution is obtained;

[0025] (3) Cast the film casting solution in step (2) onto a glass plate, and scrape it into a liquid film with a thickness of 600 microns with a scraper, that is, a carbon black / carboxylated nitrile composite...

Embodiment 2

[0028] A kind of preparation method of carboxylated nitrile rubber composite film for electromagnetic shielding of the present embodiment, the steps are as follows:

[0029] (1) Add 1.5 grams of nano-carbon black to 8.5 grams of 30% polyethylenimine cross-linking agent aqueous solution, and stir at 80°C for 3 hours to obtain a mixed solution of nano-carbon black / polyethylenimine cross-linking agent;

[0030] (2) Add 1.5 grams of nano-carbon black / polyethylenimine crosslinking agent mixed solution prepared in step (1) to 10 grams of nitrile rubber emulsion, and stir at 60°C for 3 hours to obtain nano-carbon black / polyethylenimine Pyridine crosslinking agent / carboxylated nitrile latex blended solution, after standing for defoaming, polymer casting solution is obtained;

[0031] (3) Cast the film casting solution in step (3) onto a glass plate, scrape it into a liquid film with a thickness of 700 microns with a scraper, and immerse the glass plate with a liquid film in 50 grams o...

Embodiment 3

[0034] A kind of preparation method of carboxylated nitrile rubber composite film for electromagnetic shielding of the present embodiment, the steps are as follows:

[0035] (1) Add 1.0 g of nano-carbon black to 9.0 g of a 50% polyethylenimine cross-linking agent aqueous solution, and stir at 85° C. for 2.5 hours to obtain a mixed solution of nano-carbon black / polyethylenimine cross-linking agent;

[0036] (2) Add 1.4 grams of nano-carbon black / polyethylenimine crosslinking agent mixed solution prepared in step (1) to 10 grams of nitrile rubber emulsion, and stir at 70°C for 2.5 hours to obtain nano-carbon black / polynitrogen Propidium crosslinking agent / carboxylated nitrile latex blend solution, after standing for defoaming, polymer casting solution is obtained;

[0037] (3) Cast the film casting solution in step (2) onto a glass plate, scrape it into a liquid film with a thickness of 1200 microns with a scraper, and immerse the glass plate with a liquid film in 50 grams of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com