Molybdenum-aluminum compatible etching solution and etching method

A technology compatible with etching, molybdenum and aluminum, applied in the field of etching solution, can solve the problems of excessive etching rate of molybdenum on the upper layer, residual material in the back layer, affecting product quality, etc., and achieve smooth etching angle, balanced etching, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

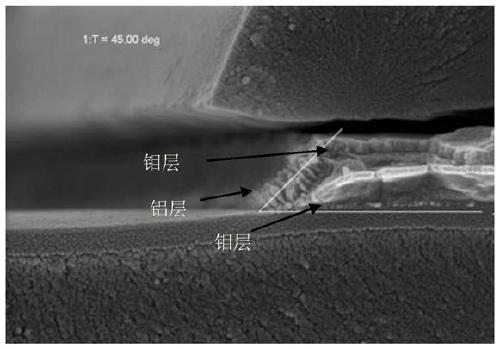

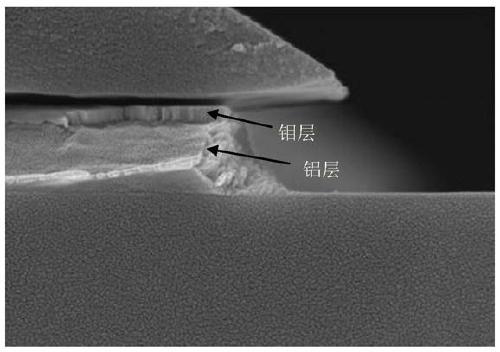

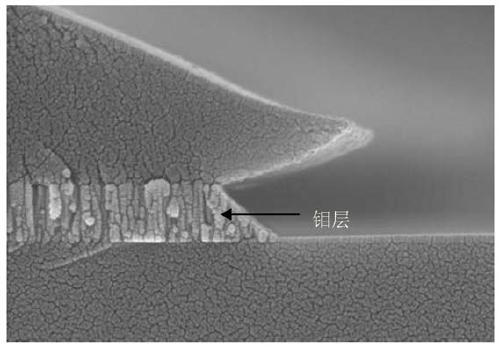

Image

Examples

Embodiment 1

[0026] A kind of molybdenum-aluminum compatible etchant provided by the present invention, according to percentage by weight, measure respectively the phosphoric acid of 60%, the nitric acid of 2.8%, the content of acetic acid is 19%, the content of chloric acid is 3.5%, 4.5g potassium chlorate; 6% Surfactant, wherein the surfactant includes 1.5% cocoic acid monoethanolamide, 1.5% cocoic acid diethanolamide, 1.5% lauryl amidopropyl betaine, 1.5% tricitric acid Butyl ester; 1% metal inhibitors, including 0.4% sodium molybdate, 0.3% sodium tolyltriazole, 0.3% dimercaptothiadiazole disodium salt; 2.5% P-hydroxybenzoic acid additive and the remaining water; add 1 / 3 of the required pure water to the batching tank, add the required amount of nitric acid under stirring, and mix the chloric acid evenly; add it to the mixed solution while stirring Add phosphoric acid and acetic acid and mix evenly, then add 1 / 3 of the required pure water and stir thoroughly; then add surfactants, metal...

Embodiment 2

[0028] The difference between embodiment 2 and the molybdenum-aluminum compatible etching solution of embodiment 1 is that 3% nitric acid, 2% chloric acid, 3g potassium chlorate, comprise 0.4% sodium molybdate, 0.2% methyl Sodium benzotriazole and 0.2% disodium dimercaptothiadiazole; additives are 1.5% p-hydroxybenzoic acid and 1% sodium citrate.

Embodiment 3

[0030] The difference between embodiment 3 and embodiment 1 is that 3% nitric acid, 3% chloric acid, 6g potassium chlorate comprise 0.4% sodium molybdate, 0.4% tolyltriazole sodium in the metal inhibitor and 0.4% dimercaptothiadiazole disodium salt; additives are 1.5% p-hydroxybenzoic acid and 2% sodium citrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com