Substrate including polymer and ceramic cold-sintered material

A technology of polymers and mixed materials, applied in circuits, electrical components, capacitors, etc., can solve the problems of high-frequency ceramic dielectric substrates lacking high mechanical stability and high thermal conductivity, so as to prevent thermal stress cracking and improve thermal shock resistance sex, stress-relieving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Example 1 - Electrical Properties

[0076] In one embodiment, the Na2 Mo 2 o 7 The powder is mixed with polyetherimide (PEI) according to the following composition: (1-x)Na 2 Mo 2 o 7 - xPEI (x=0 vol%, 10 vol%, 20 vol%, 30 vol%, 40 vol%, 50 vol%). The mixture was ball milled in ethanol for 24 hours and then dried at 85 °C.

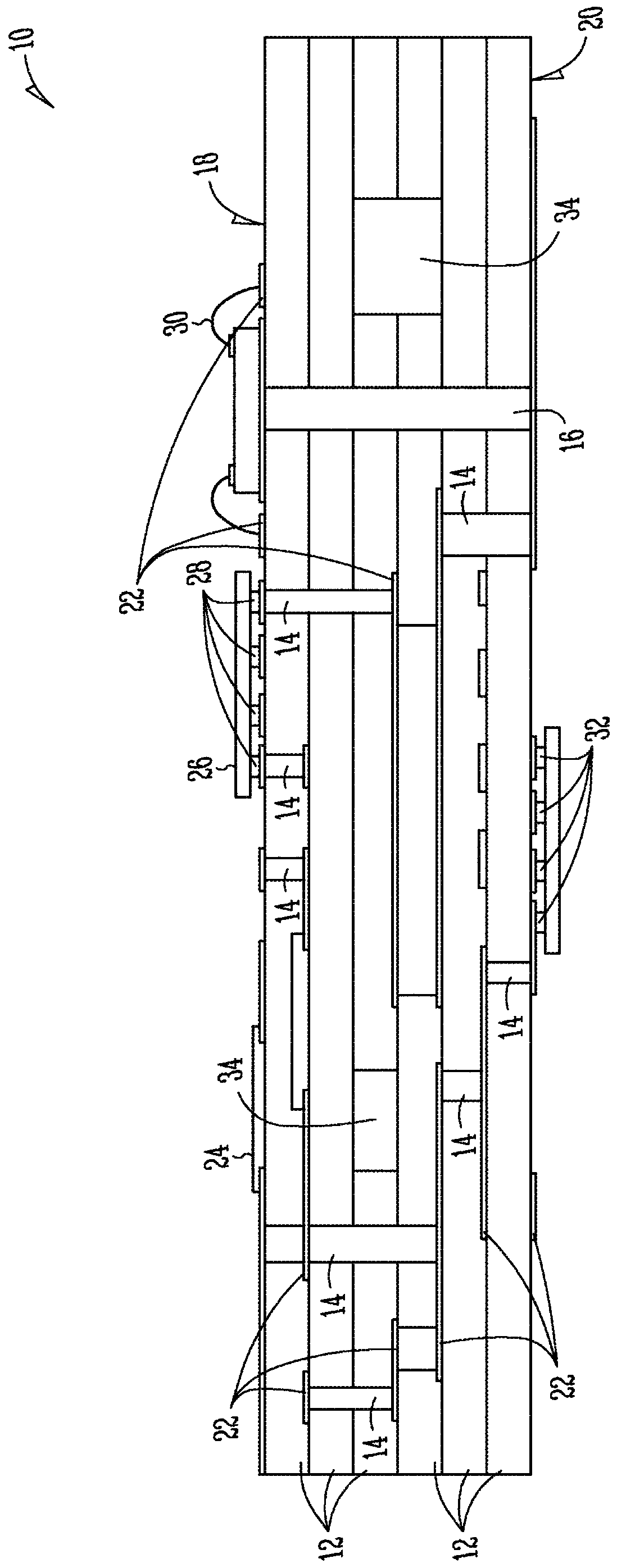

[0077] (1-x)Na 2 Mo 2 o 7 Multilayer composite of xPEI (x=0 vol%, 10 vol%, 20 vol%) and silver electrodes. First, the (1-x)Na 2 Mo 2 o 7 - xPEI powder was mixed with a solution of 95 wt% methyl ethyl ketone (MEK) and 5 wt% QPAC 40 resin (Empower Materials, Newark, DE, USA) and ball milled for 12 to 24 hours. Then, 66.3 wt% methyl ethyl ketone (MEK), 28.4 wt% QPAC 40 resin and 5.3 wt% butyl benzyl phthalate S-160 (Tape Casting Warehouse, Morrisville, PA, USA) were added to the slurry , then ball milled for 24 hours and rolled for 1 to 2 hours (MX-T6-S Analog Tube Roller, Scilogex, Rocky Hill, CT, USA). Then, using a laboratory belt ca...

Embodiment 2

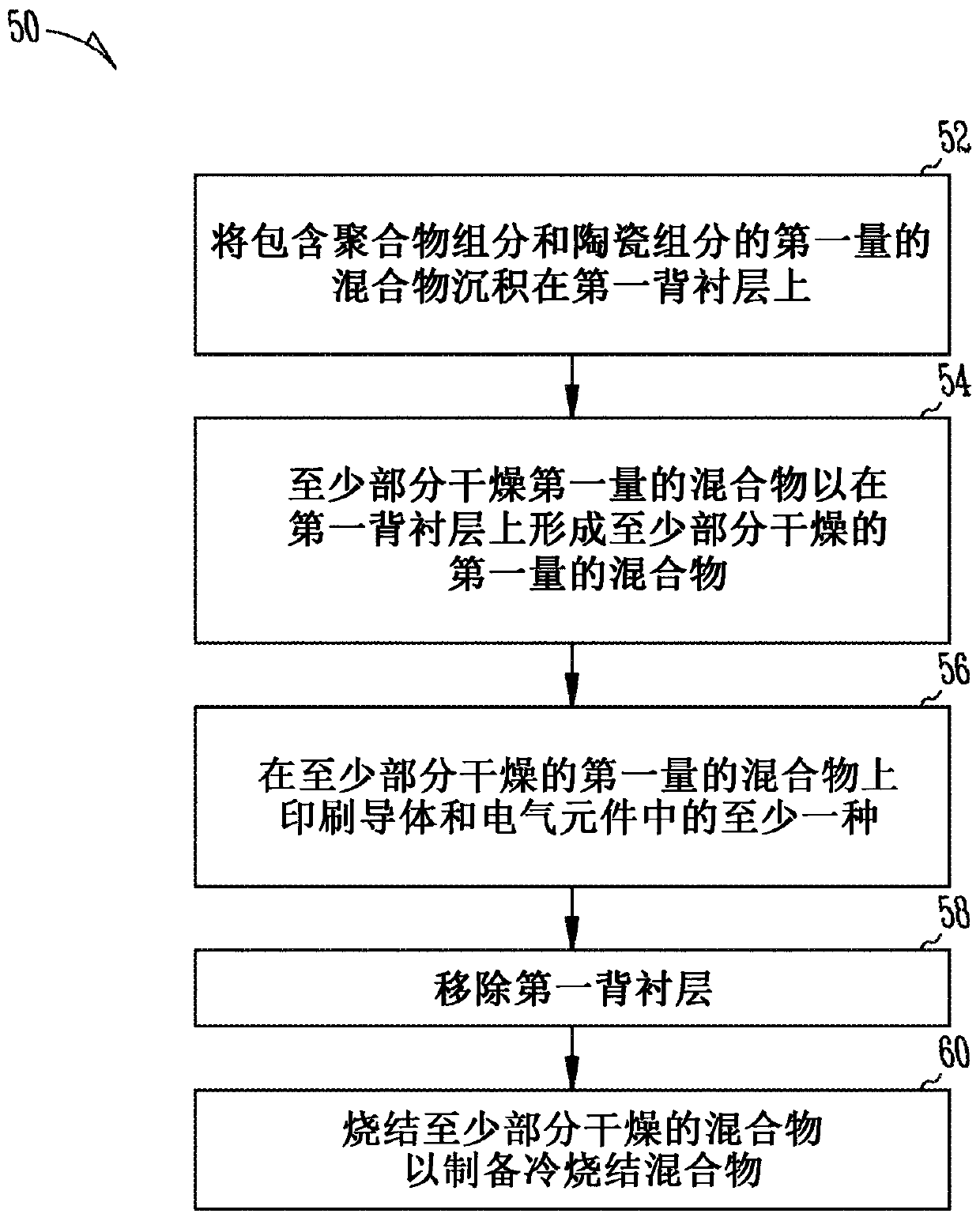

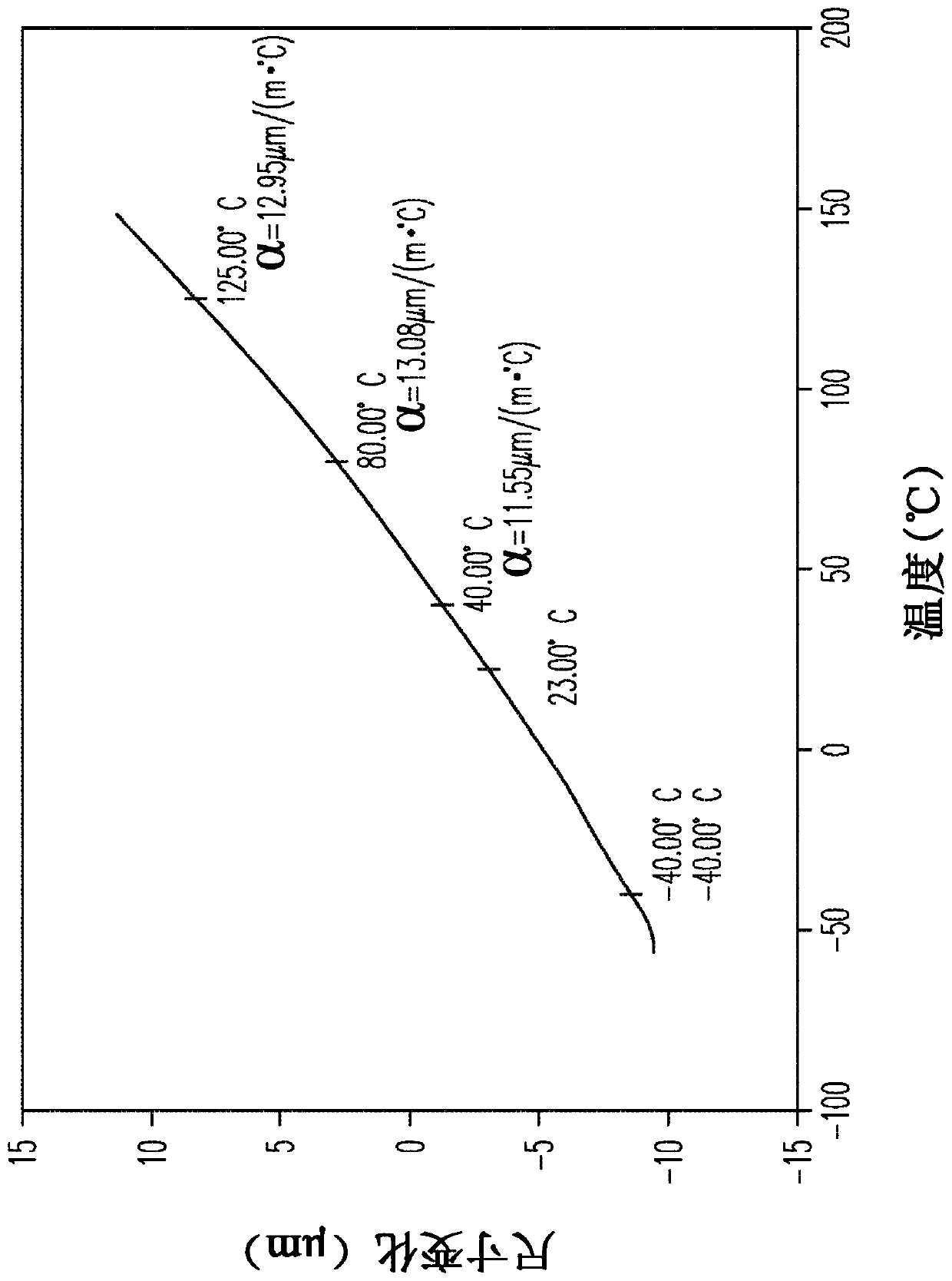

[0081] Embodiment 2 - coefficient of thermal expansion

[0082] The thermal expansion coefficients of the cold-sintered hybrid materials were measured using a TA Instruments thermomechanical analyzer TMA Q400, and the data were analyzed using TA Instruments' Universal Analysis V4.5A.

[0083] The samples were reshaped to form round pellets with a diameter of 13 mm and a thickness of 2 mm to fit the TMA Q400 equipment. Put the sample into TMAQ400, heat to 150°C (@20°C / min) to release moisture and stress, then cool to -80°C (@20°C / min) to start the actual thermal expansion coefficient measurement. The sample was heated from -80°C to 150°C at a temperature of 5°C per minute, and the change of displacement with temperature was measured.

[0084] The measured data are then loaded into the analysis software and the coefficient of thermal expansion is calculated using the αx1-x2 method. This method measures the dimensional change from temperature T1 to temperature T2 and converts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com