a co 2 Method for treating emulsified oil wastewater with atmosphere-responsive materials

A material treatment and emulsified oil technology, applied in chemical instruments and methods, adsorption water/sewage treatment, separation methods, etc., to achieve high separation and recovery efficiency, easy production and promotion, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

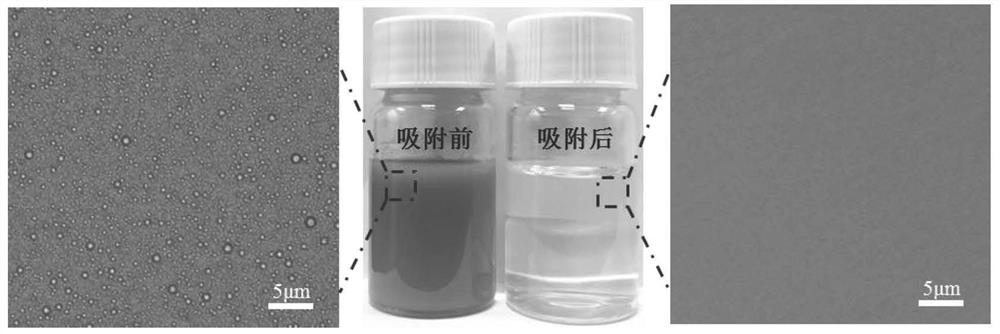

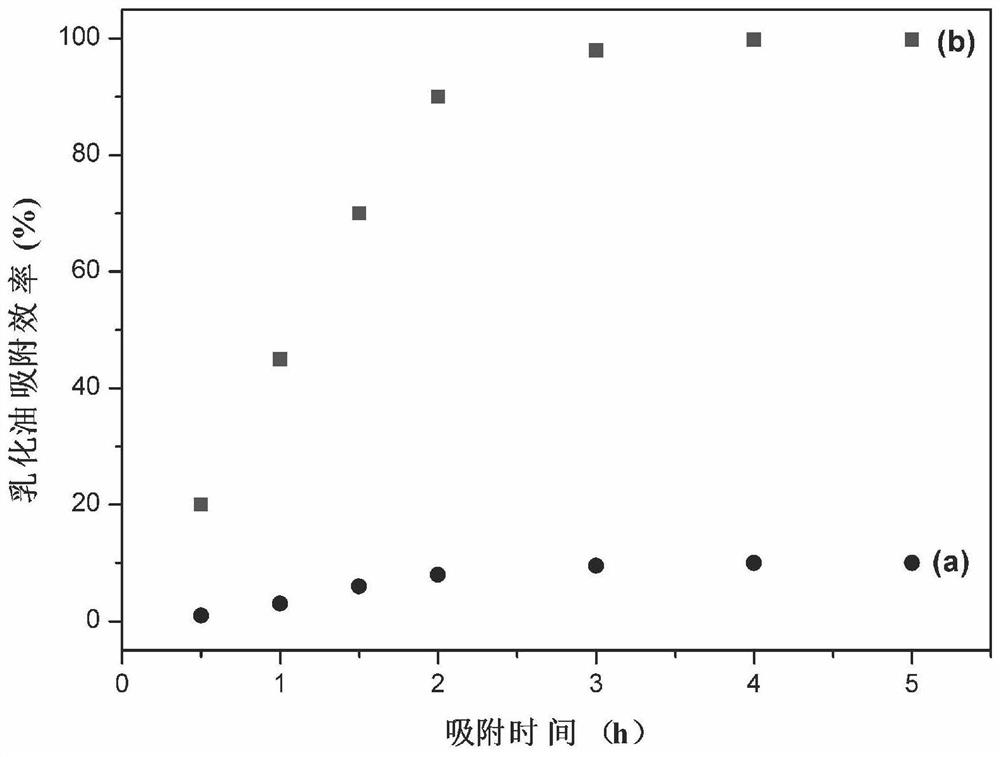

Image

Examples

Embodiment 1

[0033] (1)CO 2 Synthesis of Atmosphere Responsive Polymers

[0034] Add N,N-diethylaminoethyl methacrylate (12.62g) and 10mL 1,4-dioxane into a 50mL round bottom flask, and place it in a constant temperature oil bath at 75°C. Magnetic stirring was used to mix thoroughly. During this period, high-purity nitrogen gas was introduced for 30 minutes to fully remove the oxygen in the reaction system. Subsequently, the initiator azobisisobutyronitrile (12.62 mg) was added, and reacted at 75° C. for 12 h under nitrogen protection. After the reaction is over, connect the reaction system to the atmosphere to terminate the polymerization reaction. After the reaction flask was cooled to room temperature, the 1,4-dioxane solvent was removed by suspension evaporation, and then a small amount of dichloromethane was added to dissolve it, precipitated in 5 times the volume of n-hexane, and filtered. Then the dissolution-precipitation was repeated once, and the obtained solid precipitate wa...

Embodiment 2

[0042] (1)CO 2 Synthesis of Atmosphere Responsive Polymers

[0043] Add N-amidinododecylacrylamide (3.37g), 10mL 1,4-dioxane and dimethylformamide mixed solvent (volume ratio 2.5:1) into a 50mL round bottom flask, and place In a constant temperature oil bath device with a temperature of 100°C, they were fully mixed by means of magnetic stirring. During this period, high-purity nitrogen gas was introduced for 30 minutes to fully remove the oxygen in the reaction system. Subsequently, the initiator azobisisovaleronitrile (1.69 mg) was added, and reacted at 100° C. for 4 h under nitrogen protection. After the reaction is over, connect the reaction system to the atmosphere to terminate the polymerization reaction. After the reaction bottle was cooled to room temperature, the mixed solvent of 1,4-dioxane and dimethylformamide was removed by suspension evaporation, and then a small amount of dichloromethane was added to dissolve, precipitated in 5 times the volume of n-hexane, an...

Embodiment 3

[0051] (1)CO 2 Synthesis of Atmosphere Responsive Polymers

[0052] In a 50mL round bottom flask, add 14.83g 3-(1H-imidazol-4-yl) methyl acrylate, 10mL 1,4-dioxane, a mixed solvent of tetrahydrofuran and anisole (volume ratio 2:1:1 ), and placed in a constant temperature oil bath device with a temperature of 60°C, and fully mixed by means of magnetic stirring. During this period, high-purity nitrogen gas was introduced for 30 minutes to fully remove the oxygen in the reaction system. Subsequently, the initiator dimethyl azobisisobutyrate (59.32 mg) was added, and reacted at 60° C. for 36 h under the protection of nitrogen. After the reaction is over, connect the reaction system to the atmosphere to terminate the polymerization reaction. After the reaction flask was cooled to room temperature, the mixed solvent of 1,4-dioxane, tetrahydrofuran and anisole was removed by suspension evaporation, and then a small amount of dichloromethane was added to dissolve, precipitated in 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com