Synthesis method of polyepoxysuccinate

A technology of polyepoxysuccinate and synthesis method, which is applied in the field of synthesis of polyepoxysuccinate, can solve problems such as poor scale inhibition performance, achieve excellent scale inhibition performance, simple operation, and do not pollute the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

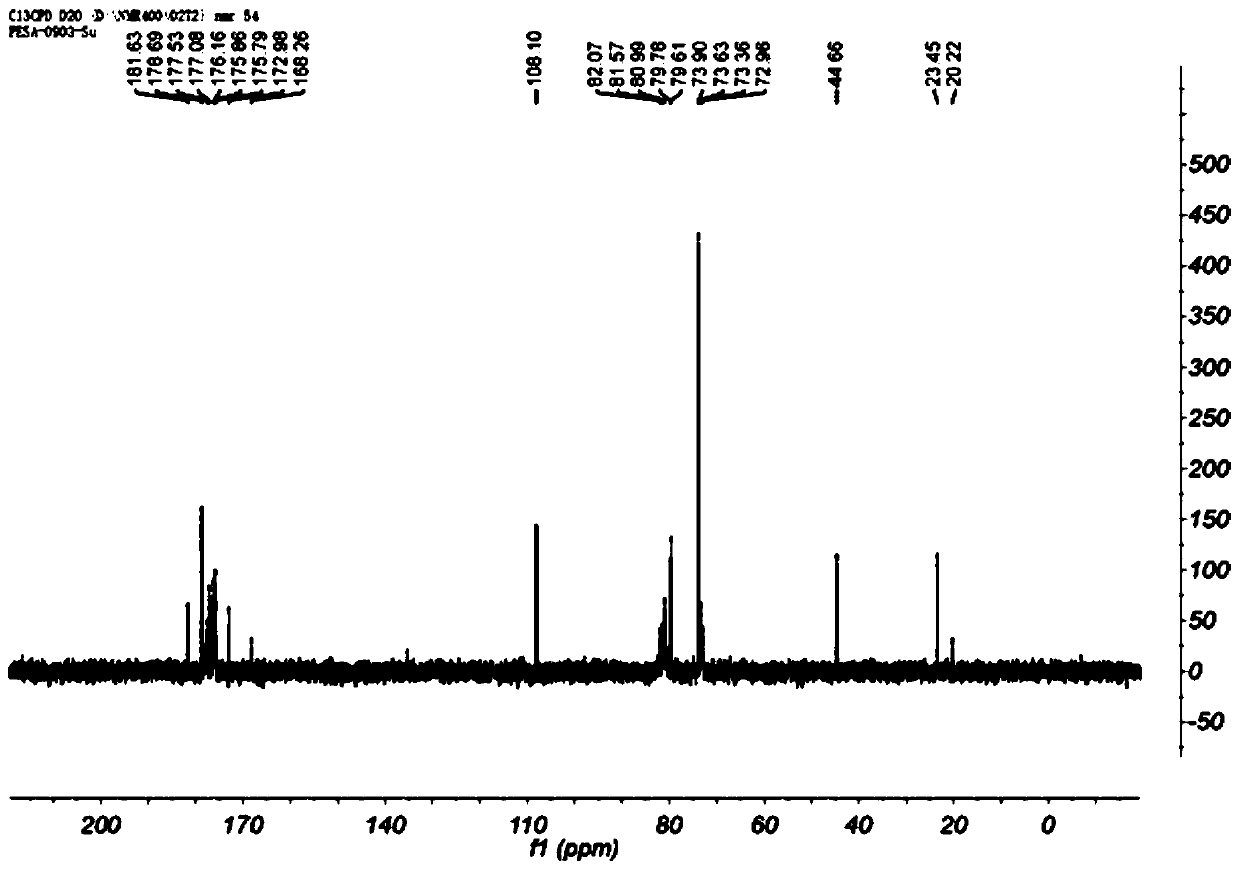

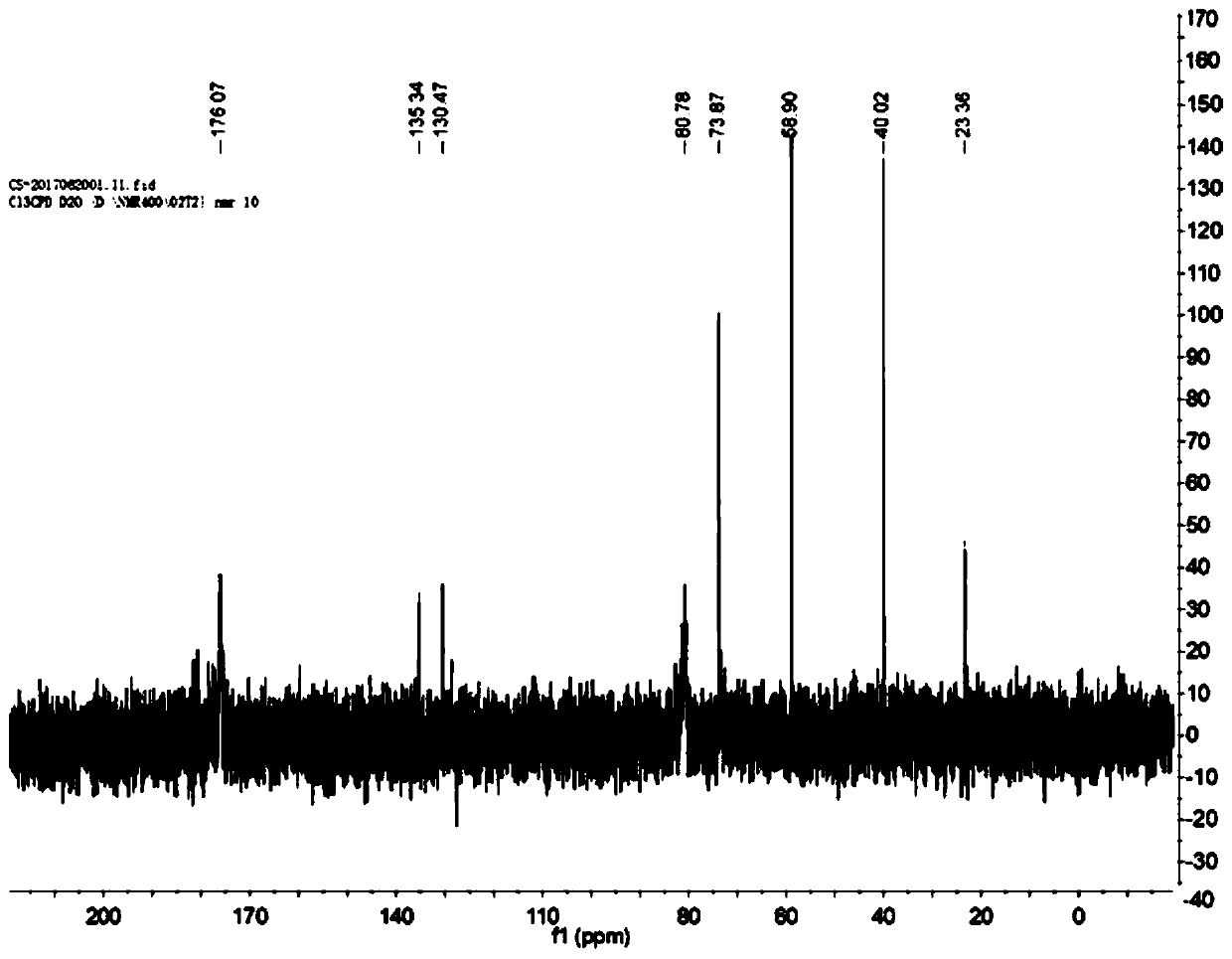

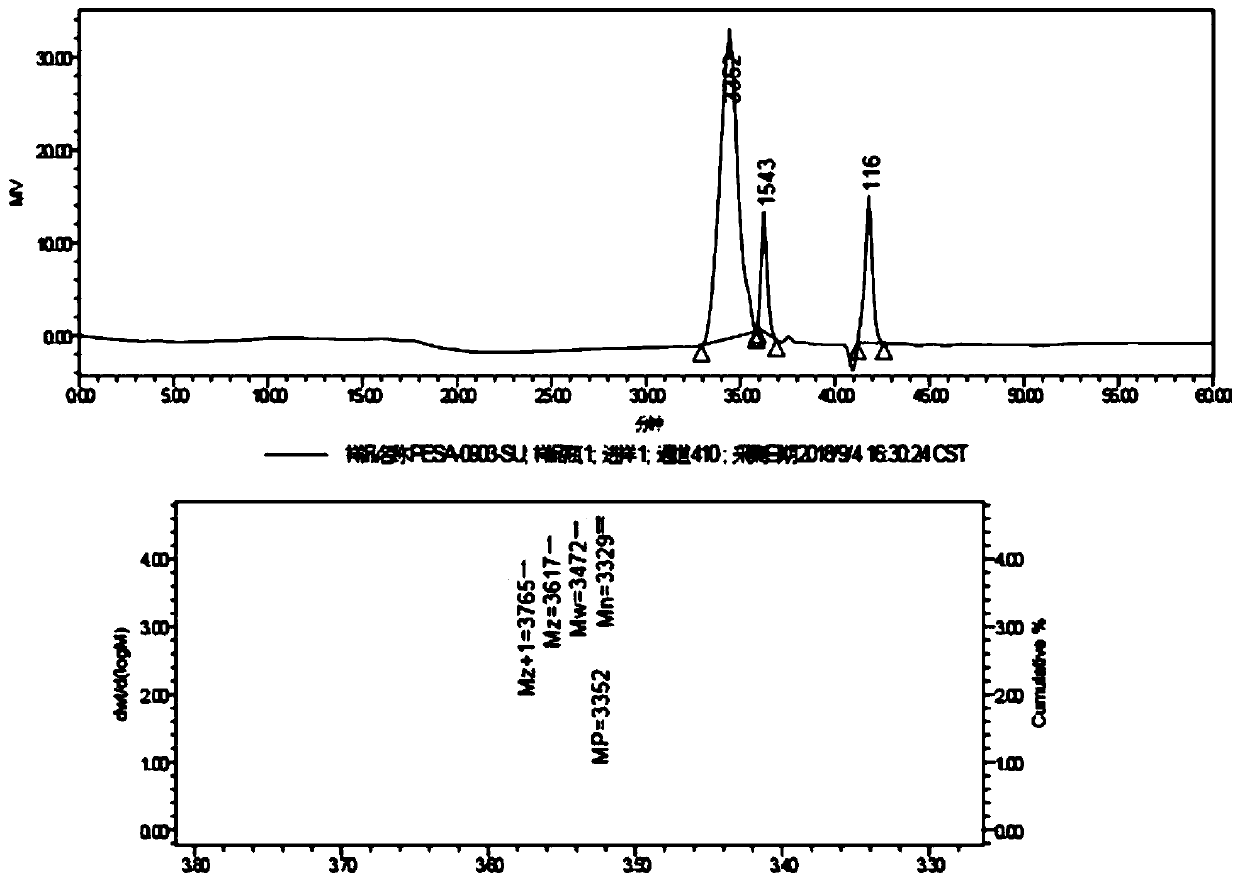

Image

Examples

Embodiment 1

[0031] (1) Add 300g of water to the reactor, then add 200g of maleic anhydride, then heat to 40°C and stir to completely dissolve the maleic anhydride.

[0032] (2) Then add alkali solution to the reaction kettle, adjust the pH to be 6, after the temperature in the kettle is stabilized at 55°C, add 1g of ruthenium catalyst;

[0033] (3) When the temperature in the kettle stabilizes to 65°C, add 300g of hydrogen peroxide to the reaction kettle, and at the same time add dropwise sodium hydroxide solution to keep the pH in the kettle between 4-6 and the temperature at 65-70°C. After the hydrogen peroxide was added dropwise, keep the temperature in the kettle at 65°C, pH = 6, and react for 3 hours.

[0034] (4) After the reaction is completed, the temperature of the system is reduced to 40 degrees, and the lye is added to adjust the pH=9, and kept stirring for 1 hour, and then dehydrated with a vacuum pump, the vacuum degree is -0.08-0.09MPa, and 250g of water is removed;

[0035...

Embodiment 2

[0038] (1) Add 200g of water to the reaction kettle, then add 100g of maleic anhydride, then heat to 40°C and stir to completely dissolve the maleic anhydride.

[0039] (2) Add alkaline solution to the reaction kettle then, adjust the pH to be 6, after the temperature in the kettle is stabilized at 55°C, add 2g of ruthenium catalyst;

[0040] (3) When the temperature in the kettle stabilizes to 65°C, add 200g of hydrogen peroxide to the reaction kettle, and dropwise add sodium hydroxide solution at the same time to keep the pH in the kettle between 4-6 and the temperature at 65-70°C. After the hydrogen peroxide was added dropwise, keep the temperature in the kettle at 65°C, pH = 6, and react for 3 hours.

[0041] (4) After the reaction is completed, the temperature of the system is reduced to 40 degrees, and the lye is added to adjust the PH=9, and kept stirring for 1 hour, and then dehydrated with a vacuum pump, the vacuum degree is -0.08MPa, and 400g of water is removed;

...

Embodiment 3

[0044] (1) Add 260g of water to the reactor, then add 150g of maleic anhydride, then heat to 40°C and stir to completely dissolve the maleic anhydride.

[0045] (2) Then add alkali solution to the reaction kettle, adjust the pH to be 6, after the temperature in the kettle is stabilized at 55°C, add 1.5g of ruthenium catalyst;

[0046] (3) When the temperature in the kettle stabilizes to 65°C, add 200g of hydrogen peroxide to the reaction kettle, and dropwise add sodium hydroxide solution at the same time to keep the pH in the kettle between 4-6 and the temperature at 65-70°C. After the hydrogen peroxide was added dropwise, keep the temperature in the kettle at 65°C, pH = 6, and react for 3 hours.

[0047] (4) After the reaction is completed, the temperature of the system is reduced to 40 degrees, and the lye is added to adjust the pH=9, and kept stirring for 1 hour, and then dehydrated with a vacuum pump, the vacuum degree is -0.09MPa, and 450g of water is removed;

[0048] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com