Method for electrochemical synthesis of carbazole compound

A technology for carbazoles and compounds, which is applied in the field of electrochemical synthesis of carbazoles, can solve problems such as unreported, and achieve the effects of simple and easy operation, easy handling and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

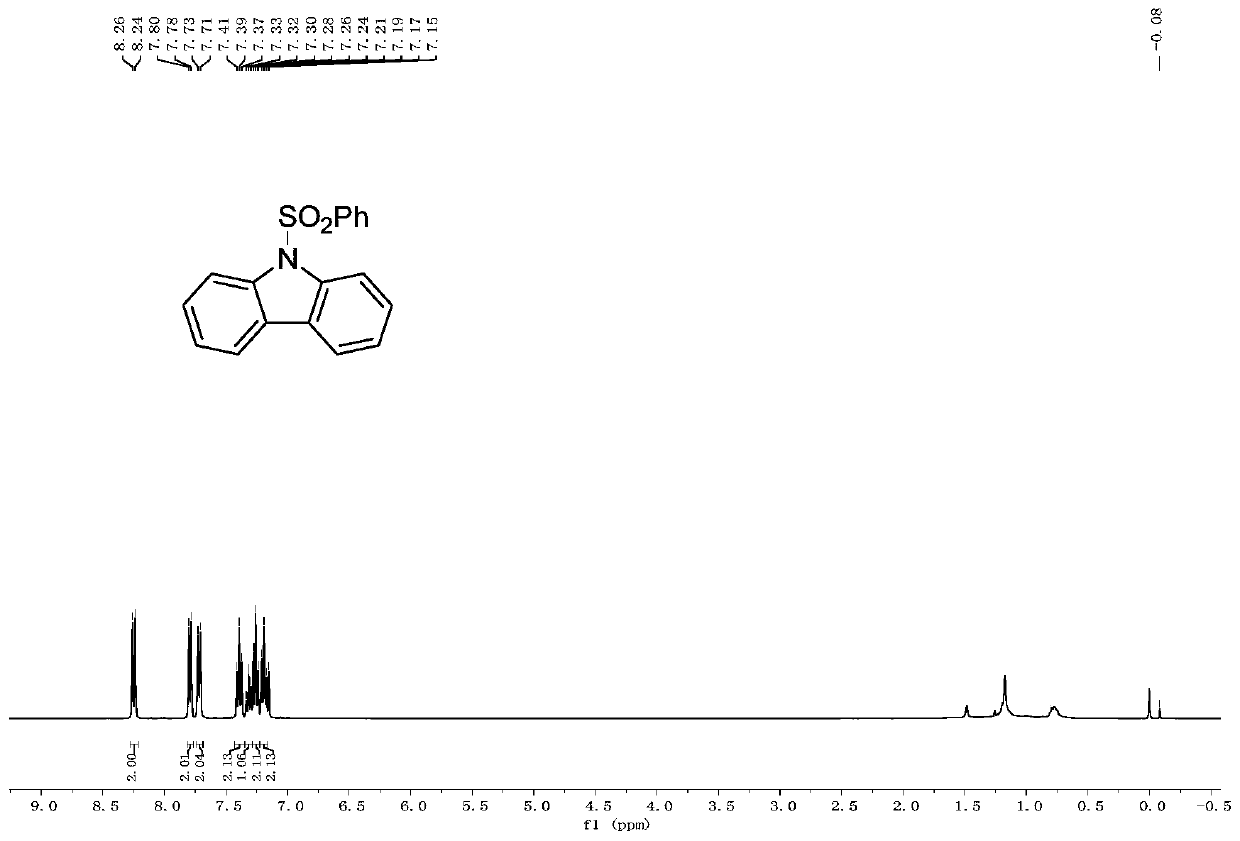

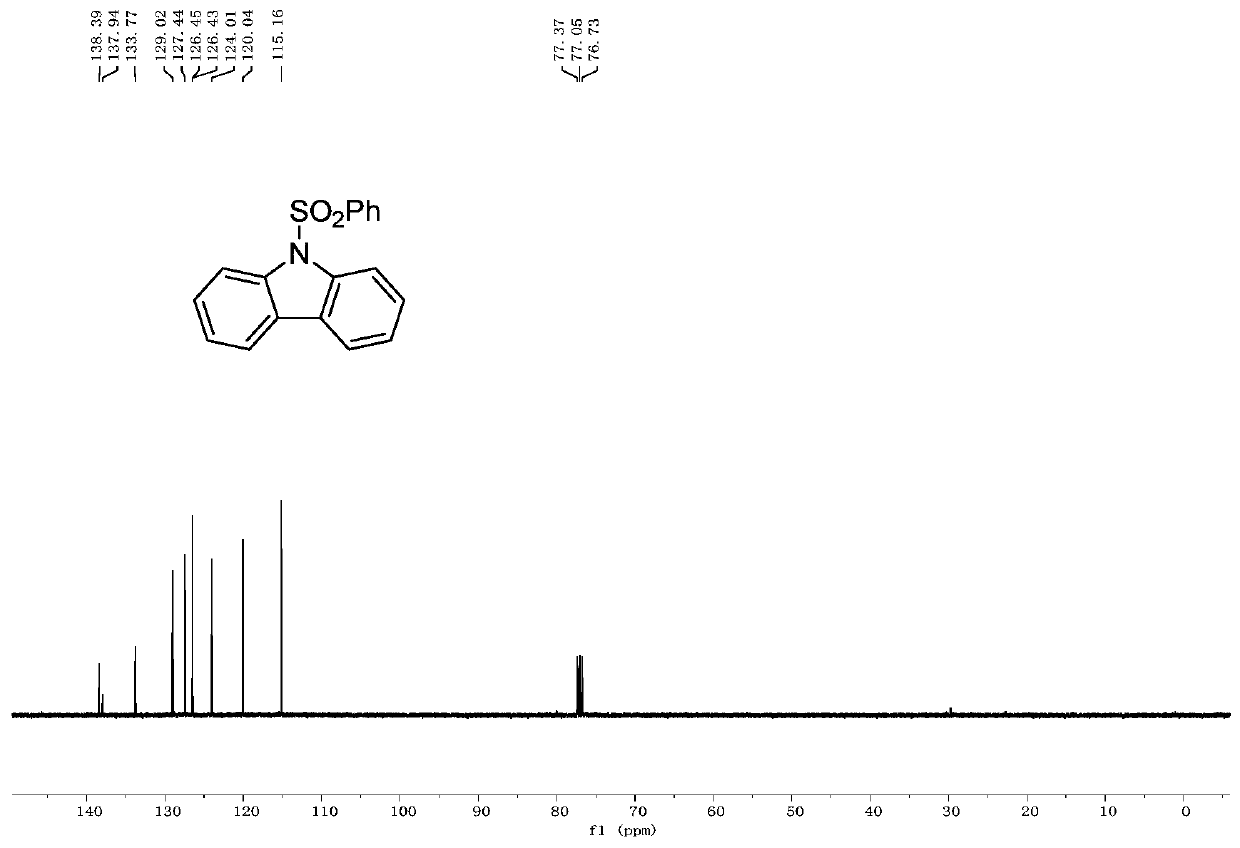

Embodiment 1

[0059]

[0060] In a 10mL three-necked flask, add 2-benzenesulfonylaminobiphenyl (0.2mmol), tetrabutylammonium hexafluorophosphate (0.4mmol), tetrabutylammonium iodide (0.02mmol), trifluoroethanol (5ml), Dichloromethane (5ml). The carbon rod was used as the anode, and the platinum sheet was used as the cathode. Under the conditions of room temperature and nitrogen atmosphere, the electrolytic reaction was performed with a constant current of 1.7mA for 12 hours. After the reaction was completed, the solvent was removed with a rotary evaporator, and the residue was purified by flash silica gel column chromatography (ethyl acetate:petroleum ether=1:50) to obtain a white solid product with a yield of 90%;

[0061] 1 H NMR (400MHz, CDCl 3 )δ8.25(d, J=8.4Hz, 2H), 7.79(d, J=7.7Hz, 2H), 7.72(m, 2H), 7.39(t, J=7.6Hz, 2H), 7.32(t, J=7.2Hz, 1H), 7.26(t, J=7.5Hz, 2H), 7.19(t, J=7.7Hz, 2H).

[0062] 13 C NMR (101MHz, CDCl 3 )δ138.39, 137.94, 133.77, 129.02, 127.44, 126.45, 126.43,...

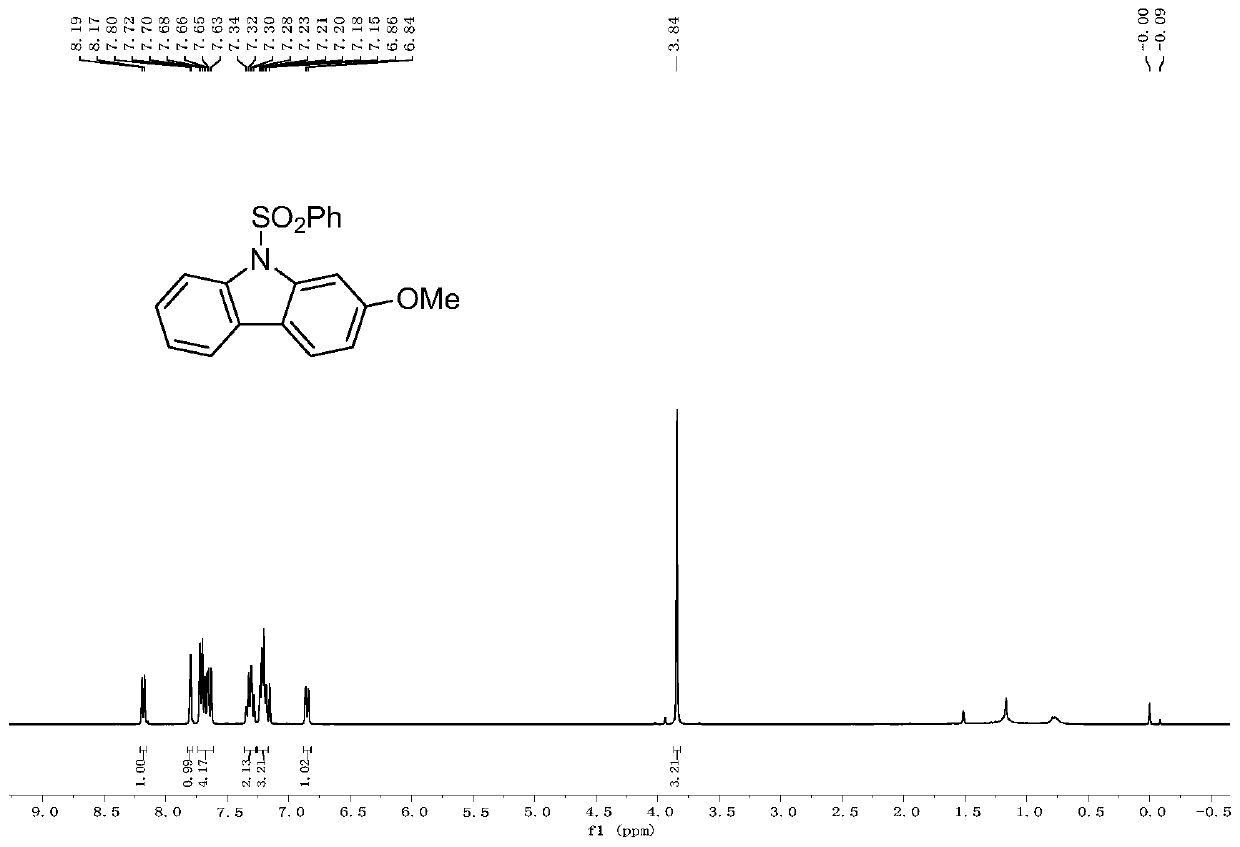

Embodiment 2

[0064]

[0065] In a 10mL three-necked flask, add N-(4'-methoxy-[1,1'-biphenyl]-2-yl)benzenesulfonamide (0.2mmol), tetrabutylammonium hexafluorophosphate (0.4mmol) , tetrabutylammonium iodide (0.02mmol), trifluoroethanol (5ml), dichloromethane (5ml). The carbon rod was used as the anode, and the platinum sheet was used as the cathode. Under the conditions of room temperature and nitrogen atmosphere, the electrolytic reaction was performed with a constant current of 1.7mA for 12 hours. After the reaction was completed, the solvent was removed with a rotary evaporator, and the residue was purified by flash silica gel column chromatography (ethyl acetate:petroleum ether=1:50) to obtain a white solid product with a yield of 95%;

[0066] 1 H NMR (400MHz, CDCl 3 )δ8.18(d,J=8.3Hz,1H),7.80(s,1H),7.72-7.63(m,4H),7.34-7.28(m,2H),7.23-7.18(m,3H),6.85 (d,J=8.5Hz,1H),3.84(s,3H).

[0067] 13 C NMR (101MHz, CDCl 3 )δ159.84, 139.71, 138.32, 137.87, 133.82, 129.06, 126.54, 126.44, 12...

Embodiment 3

[0069]

[0070] Add N-(2-(benzo[d][1,3]dioxa-5 base)phenyl)benzenesulfonamide (0.2mmol), tetrabutylammonium hexafluorophosphate (0.4 mmol), tetrabutylammonium iodide (0.02mmol), trifluoroethanol (5ml), dichloromethane (5ml). The carbon rod was used as the anode, and the platinum sheet was used as the cathode. Under the conditions of room temperature and nitrogen atmosphere, the electrolytic reaction was performed with a constant current of 1.7mA for 12 hours. After the reaction was completed, the solvent was removed by a rotary evaporator, and the residue was purified by flash silica gel column chromatography (ethyl acetate:petroleum ether=1:50) to obtain a white solid product with a yield of 93%;

[0071] 1 H NMR (400MHz, CDCl 3 )δ8.16(d, J=8.3Hz, 1H), 7.75(s, 1H), 7.65(d, J=8.7Hz, 2H), 7.59(d, J=6.9Hz, 1H), 7.34-7.26( m,2H),7.24-7.16(m,3H),7.10(s,1H),5.94(s,2H).

[0072] 13 C NMR (101MHz, CDCl 3 )δ 148.19, 145.45, 138.37, 137.67, 133.78, 133.31, 129.03, 126.76, 126....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com