A polysilazane with excellent spinning performance and its preparation and melt spinning

A polysilazane and melt-spinning technology, which is applied in melt-spinning, textiles and papermaking, single-component synthetic polymer rayon, etc., can solve the problems of complex polymerization device, high polymerization temperature and high cracking temperature, and achieve The preparation process is simple, the polymerization device is simple, and the preparation process is mature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

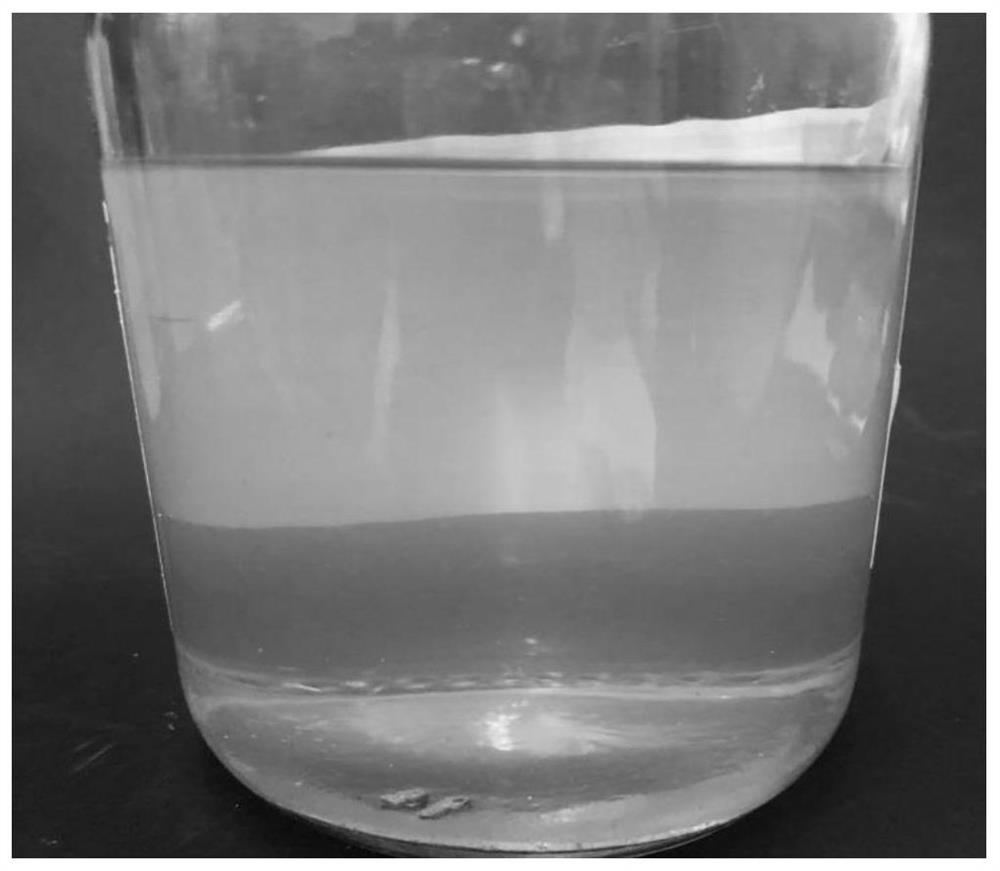

[0040] Step a: Add 4000ml normal hexane, 503g (4.4mol) methylhydrogen dichlorosilane and 297g ( 2.3mol) dimethyldichlorosilane, N 2 After replacing the air in the bottle, feed NH at a flow rate of 100ml / min 3 , Stir at 0°C for 20h. After the reaction, filter the by-product NH of the ammonolysis reaction4 Cl, fractional distillation of n-hexane to obtain figure 1 700 g of the shown colorless, transparent, oily silazane oligomer with very low viscosity.

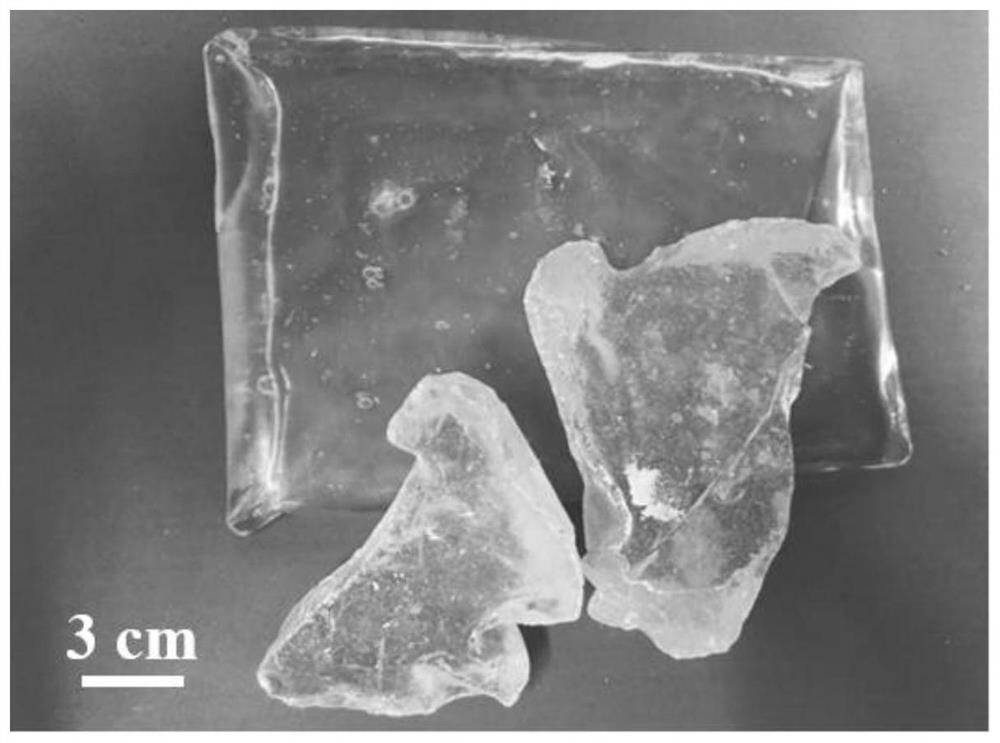

[0041] Step b: Add the silazane oligomer prepared in step a into a 500ml three-neck flask, and pass nitrogen gas for 30min after the addition is completed, and the nitrogen flow rate is 50ml / min to ensure that the oxygen in the device is completely exhausted. Stepwise polymerization is adopted, and the heating program is set: 150°C, 0.5h, 200°C, 0.5h, 250°C, 1h, 300°C, 1h, 330°C, 4h. A colorless solid thermoplastic polysilazane was prepared as figure 2 shown.

[0042] The prepared polysilazane and silazane oligomer infra...

Embodiment 2

[0045] Step a: Add 4000ml of normal hexane, 482g (4.2mol) methylhydrogen dichlorosilane and 318g ( 2.5mol) dimethyldichlorosilane, N 2 After replacing the air in the bottle, feed NH at a flow rate of 100ml / min 3 , Stir at 0°C for 20h. After the reaction, filter the by-product NH of the ammonolysis reaction 4 Cl, fractional distillation of n-hexane to obtain a colorless, transparent, oily silazane oligomer with low viscosity.

[0046] Step b and step c are the same as shown in Example 1.

Embodiment 3

[0048] Step a: Add 4000ml of normal hexane, 457g (4.0mol) methylhydrogen dichlorosilane and 343g ( 2.7mol) dimethyldichlorosilane, N 2 After replacing the air in the bottle, feed NH at a flow rate of 100ml / min 3 , Stir at 0°C for 20h. After the reaction, filter the by-product NH of the ammonolysis reaction 4 Cl, fractional distillation of n-hexane to obtain a colorless, transparent, oily silazane oligomer with low viscosity.

[0049] Step b and step c are the same as shown in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com