Flexible high-thermal-conductivity polymer nanocomposite film and preparation method thereof

A nanocomposite and polymer technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of reducing polymer plasticity and toughness, deteriorating polymer mechanical properties, and failing to meet performance requirements, etc., to achieve excellent thermal conductivity , easy mass production, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

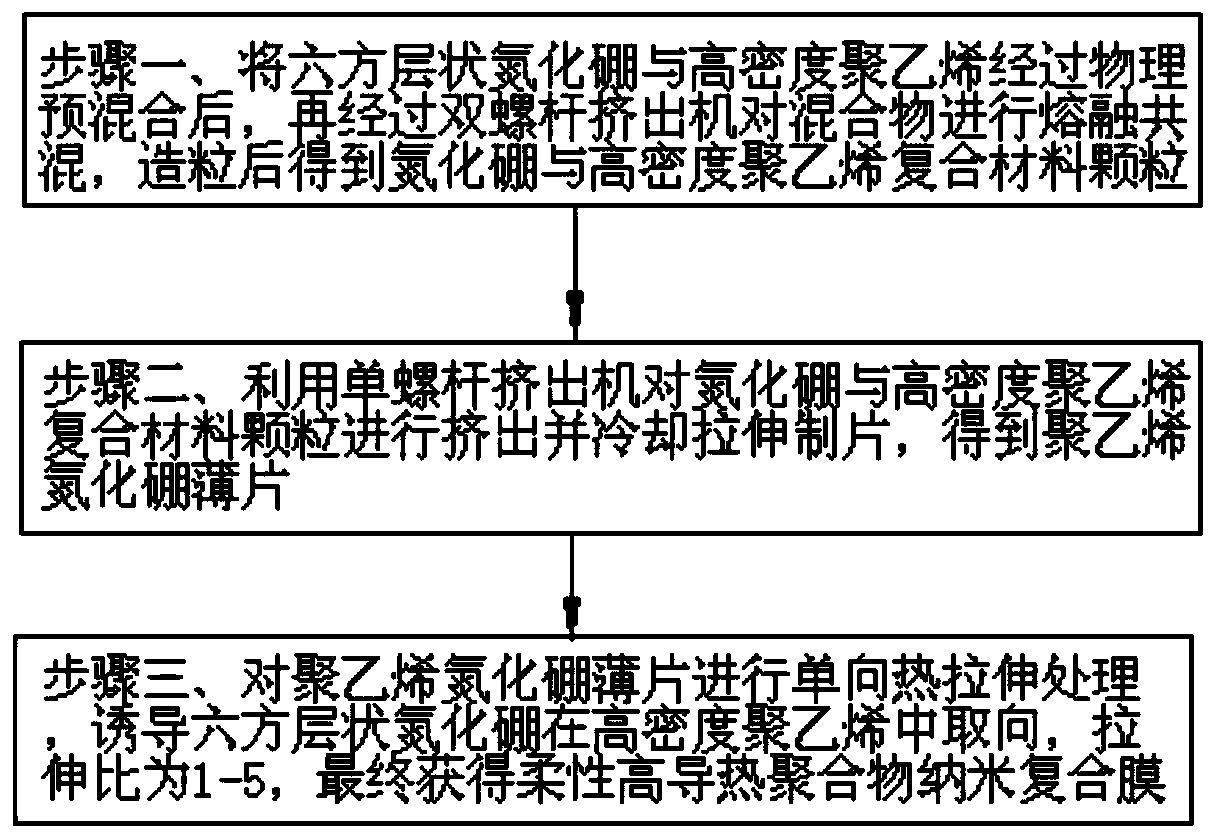

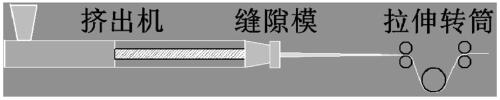

[0025] A flexible high thermal conductivity polymer nanocomposite film proposed by the present invention uses hexagonal layered boron nitride (h-BN) as a thermal conductive filler and high-density polyethylene (HDPE) as a matrix. As far as the film is concerned, the content of the thermally conductive filler determines its flexibility and thermal conductivity, and the content of the thermally conductive filler depends on its dispersion in the polymer matrix; The h-BN / HDPE mixture was melt blended by machine to increase the dispersion of h-BN in HDPE, and finally the composite material was thermally stretched to induce the orientation of layered h-BN in HDPE, so that the obtained polymer The nanocomposite film has ultrahigh thermal conductivity and excellent flexibility. Such as figure 2 As shown, the specific steps for preparing the flexible high thermal conductivity polymer nanocomposite film are as follows:

[0026] Step 1. Stir the hexagonal layered boron nitride and hig...

Embodiment 1

[0031] First, after mixing 500g of hexagonal layered boron nitride (with a particle size of 1-3mm) and 9500g of polyethylene, stir at high speed in a high-speed stirrer for 30 minutes to obtain a premixture to obtain a 5w.t.% polyethylene boron nitride mixture . Then the mixture is melted and blended by a twin-screw extruder and extruded to pelletize. After drying, it is stretched by stretching equipment at a temperature of 120°C and a stretch ratio of 1 to obtain polyethylene boron nitride. nanocomposite film. Then the film was made into a circular sample with a diameter of 25.4 mm for the measurement of thermal conductivity. The thermal conductivity of the thermally conductive polymer nanocomposite obtained in this example is 0.32W m -1 K -1 .

Embodiment 2

[0033] First, after mixing 500g of hexagonal layered boron nitride (with a particle size of 1-3mm) and 9500g of polyethylene, stir at high speed in a high-speed stirrer for 30 minutes to obtain a premixture to obtain a 5w.t.% polyethylene boron nitride mixture . Then the mixture is melted and blended by a twin-screw extruder and extruded to pelletize. After drying, it is stretched by stretching equipment at a temperature of 120°C and a stretch ratio of 2 to obtain polyethylene boron nitride. nanocomposite film. Then the film was made into a circular sample with a diameter of 25.4 mm for the measurement of thermal conductivity. The thermal conductivity of the thermally conductive polymer nanocomposite obtained in this example is 0.58W m -1 K -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com