Modified hydroxyapatite and application in water-based fireproof coating material

A hydroxyapatite and modified technology, applied in fire-resistant coatings, coatings, fibrous fillers, etc., can solve the problems of low surface activity of hydroxyapatite, limited application effect, difficult interface bonding, etc., and achieve excellent thermal performance. Stability and hydrophobicity, broad application prospects, and the effect of simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A modified hydroxyapatite, the preparation method of which comprises the following steps:

[0033] 1) Add 5g of hydroxyapatite into 100ml of N-N dimethylformamide, ultrasonically disperse in a water bath for 15min at room temperature, and disperse evenly; then add 0.5g of citric acid, and stir in an oil bath at 120°C for 6h. Filter, wash twice with deionized water, and dry under vacuum at 80°C to obtain hydroxyapatite treated with citric acid.

[0034] 2) Weigh 0.5g of aminopropyltriethoxysilane coupling agent and 200ml of absolute ethanol respectively, and ultrasonically disperse in a water bath for 30min at room temperature; then add the obtained hydroxyapatite treated with citric acid in step 1), and Stir in an oil bath at 100°C for 8 hours. After the reaction is complete, filter, wash twice with deionized water, and dry in vacuum at 80°C for 6 hours to obtain the modified hydroxyapatite.

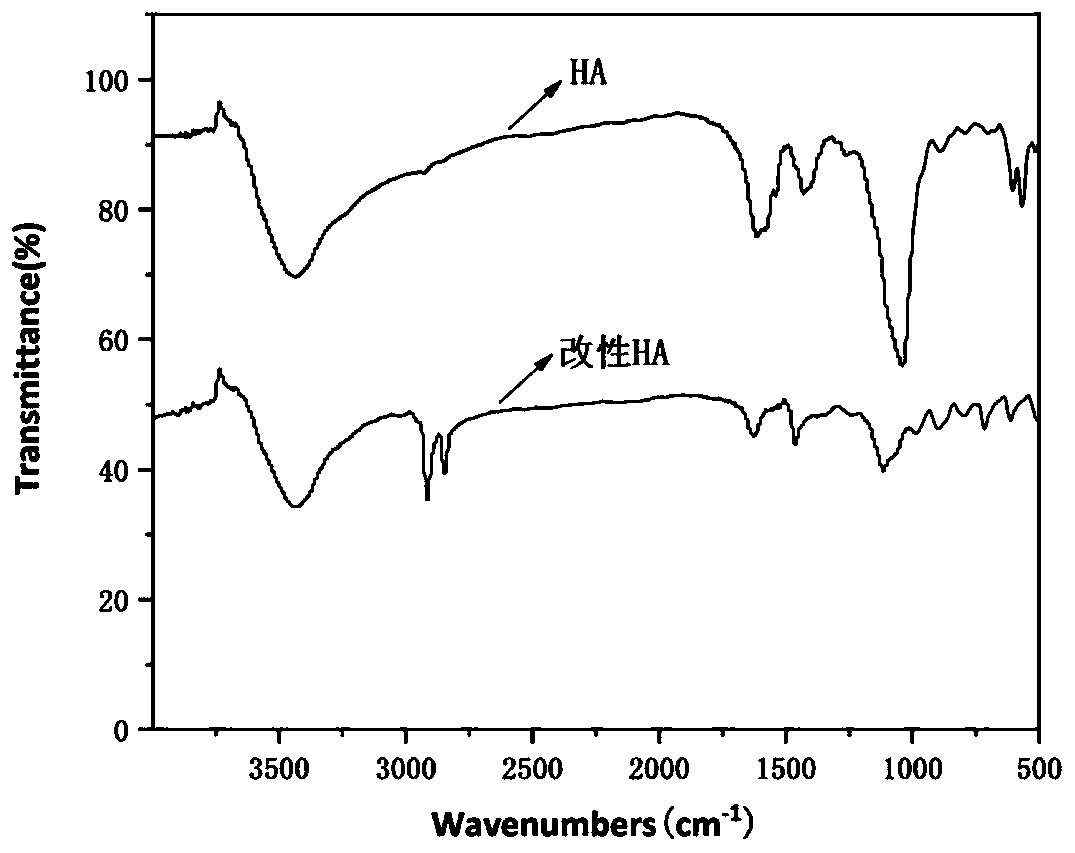

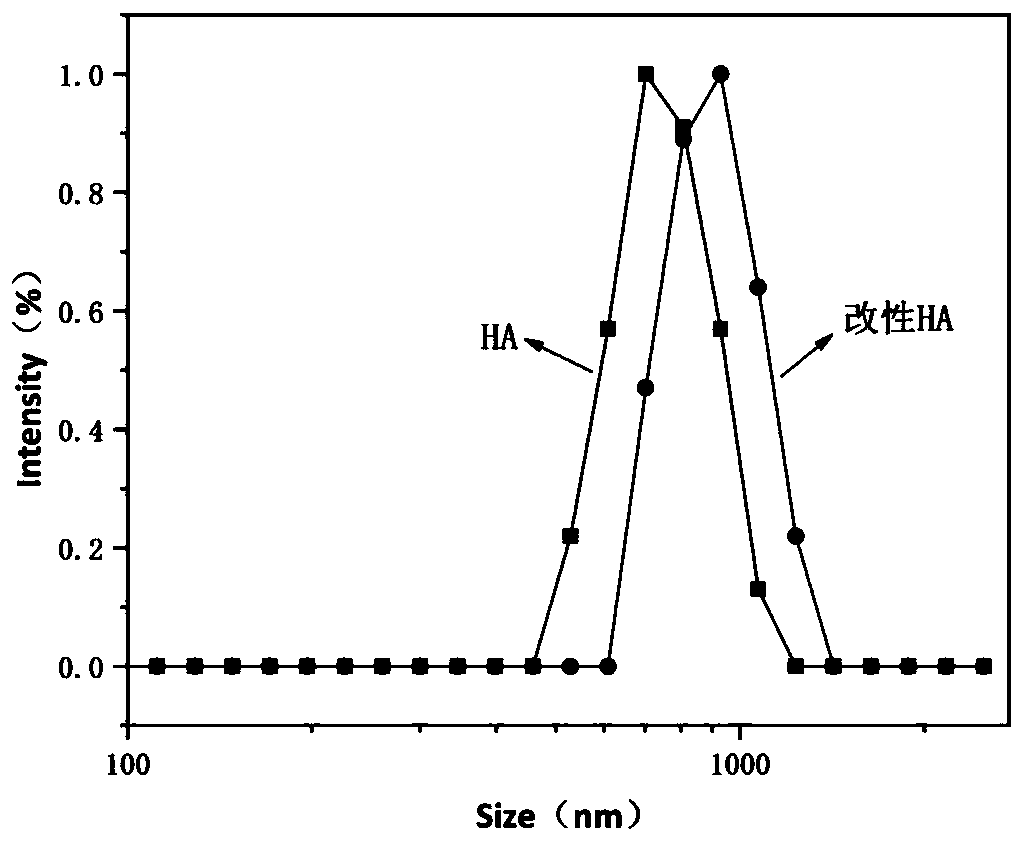

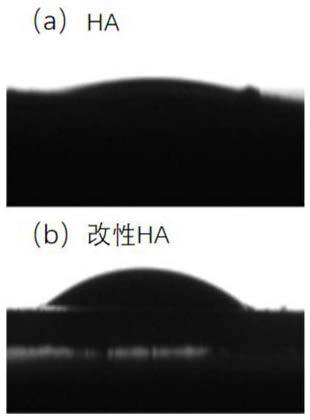

[0035] The modified hydroxyapatite obtained in this embodiment and the unmod...

Embodiment 2

[0042] A modified hydroxyapatite, the preparation method of which comprises the following steps:

[0043] 1) Add 10g of hydroxyapatite to 100ml of N-N dimethylformamide, ultrasonicate in a water bath for 20min at room temperature, and disperse evenly; then add 1g of citric acid, and stir in an oil bath at 120°C for 7h, wait until the reaction is complete, and filter , washed twice with deionized water, and vacuum-dried at 80° C. to obtain hydroxyapatite treated with citric acid.

[0044]2) Weigh 3g of 3-aminopropyltrimethoxysilane and 200ml of absolute ethanol respectively, and ultrasonically disperse in a water bath for 30min at room temperature to disperse evenly; Stir in a bath for 9 hours, and after the reaction is complete, filter, wash twice with deionized water, and vacuum-dry at 80° C. for 6 hours to obtain the modified hydroxyapatite.

[0045] Application example

[0046] The modified hydroxyapatite obtained in this example is used as an inorganic flame retardant ad...

Embodiment 3

[0050] A modified hydroxyapatite, the preparation method of which comprises the following steps:

[0051] 1) Add 8g of hydroxyapatite into 100ml of N-N dimethylformamide, ultrasonically disperse in a water bath for 15min at room temperature, and disperse evenly; then add 1.6g of citric acid, and stir in an oil bath at 110°C for 8h. Filter, wash twice with deionized water, and dry under vacuum at 80°C to obtain hydroxyapatite treated with citric acid.

[0052] 2) Weigh 2g of vinyltrimethoxysilane and 150ml of absolute ethanol respectively, and ultrasonicate in a water bath for 30min at room temperature to disperse evenly; Stir for 10 hours, and after the reaction is complete, filter, wash twice with deionized water, and vacuum dry at 80° C. for 6 hours to obtain the modified hydroxyapatite.

[0053] Application example

[0054] The modified hydroxyapatite obtained in the embodiment is used as an inorganic flame retardant additive to prepare a water-based intumescent fireproof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com