Ruminant fermented feed and production method thereof

A technology for fermenting feed and ruminants, applied in animal feed, animal feed, animal husbandry, etc., can solve the problems of poor palatability and unfavorable digestion and absorption of ruminants, achieve strong sporulation ability, and promote the development and production of intestinal flora. The effect of easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

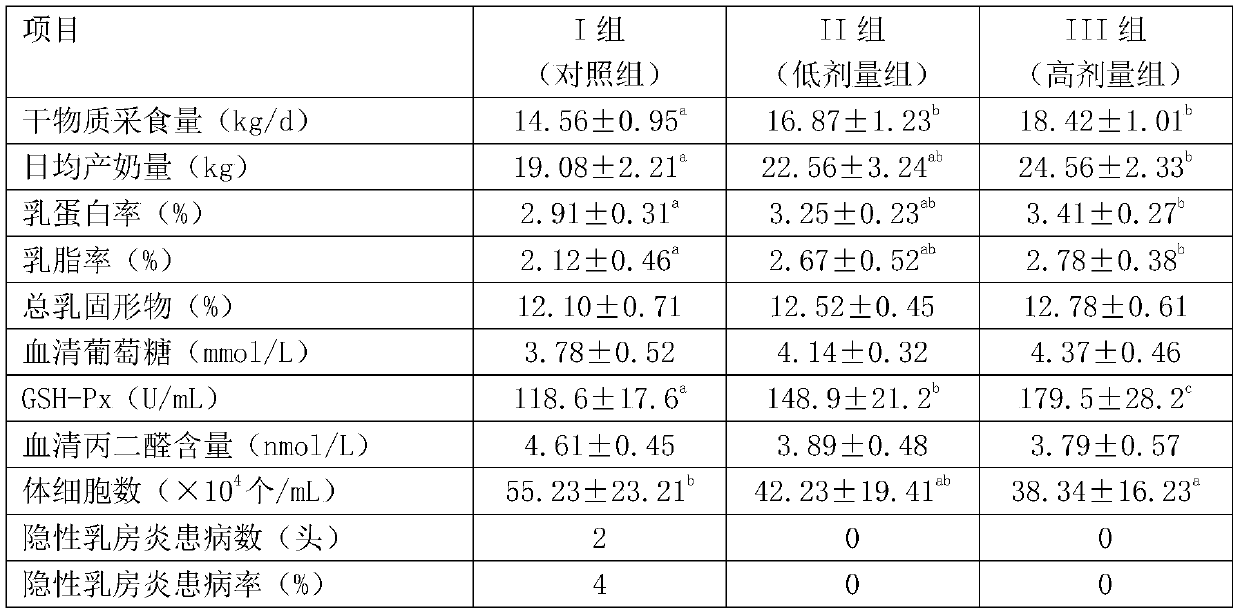

Examples

Embodiment 1

[0032] Preparation of fermented feed for ruminants:

[0033] The first step is to reduce the potassium ion content in the fermentation residue of beet molasses yeast

[0034] The fermentation residue of beet molasses yeast in this example was provided by Huoyuan Yeast Co., Ltd. The physical and chemical indicators are as follows: solid content 9.06%, total organic matter 7.61%, protein content 5.12%, soluble sugar 1.37%, ash content 1.43%, amino acid nitrogen 1.27 %, P 2 O 5 0.028%, K + 0.75%, pH=5.69.

[0035] Ammonium ion modified clinoptilolite was purchased from Zhejiang Shenshi Mining Co., Ltd. (silica content 64%-66%, density 0.9-1.1g / cm 3 ) Add it as an adsorbent to the ion exchange column. The zeolite used is a small particle size clinoptilolite adsorbent with a particle size of 1-3 mm, and a large particle size clinoptilolite adsorbent with a particle size of 3-10 mm.

[0036] The ammonium ion modified clinoptilolite used as adsorbent is loaded into Φ1000×6400mm (about 5m 3 ...

Embodiment 2

[0049] Preparation of fermented feed for ruminants:

[0050] The first step is to reduce the potassium ion content of beet molasses yeast fermentation residue

[0051] The beet molasses yeast fermentation residue in this example was provided by Huoyuan Yeast Co., Ltd. The physical and chemical indicators are as follows: solid content 9.14%, total organic matter 7.68%, protein content 5.15%, soluble sugar 1.29%, ash content 1.41%, amino acid nitrogen 1.29 %, P 2 O 5 0.031%, K + 1.02%, pH=5.86.

[0052] Ammonium ion modified clinoptilolite was purchased from Zhejiang Shenshi Mining Co., Ltd. (silica content 64%-66%, density 0.9-1.1g / cm 3 ); It is added as an adsorbent to the ion exchange column, the zeolite used is a small particle size clinoptilolite adsorbent with a particle size of 1-3mm, and a large particle size clinoptilolite adsorbent has a particle size of 3-10mm.

[0053] The ammonium ion modified clinoptilolite used as adsorbent is loaded into Φ1000×6400mm (about 5m 3 ) Jacke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com