UV oxidation method for synchronously removing pollutants and disinfection byproducts

A technology for disinfection by-products and pollutants, which is applied in the field of water treatment, can solve the problems of large amount of use, high energy consumption, and few examples of removing trace pollutants, and achieve the effect of improving control effect and oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

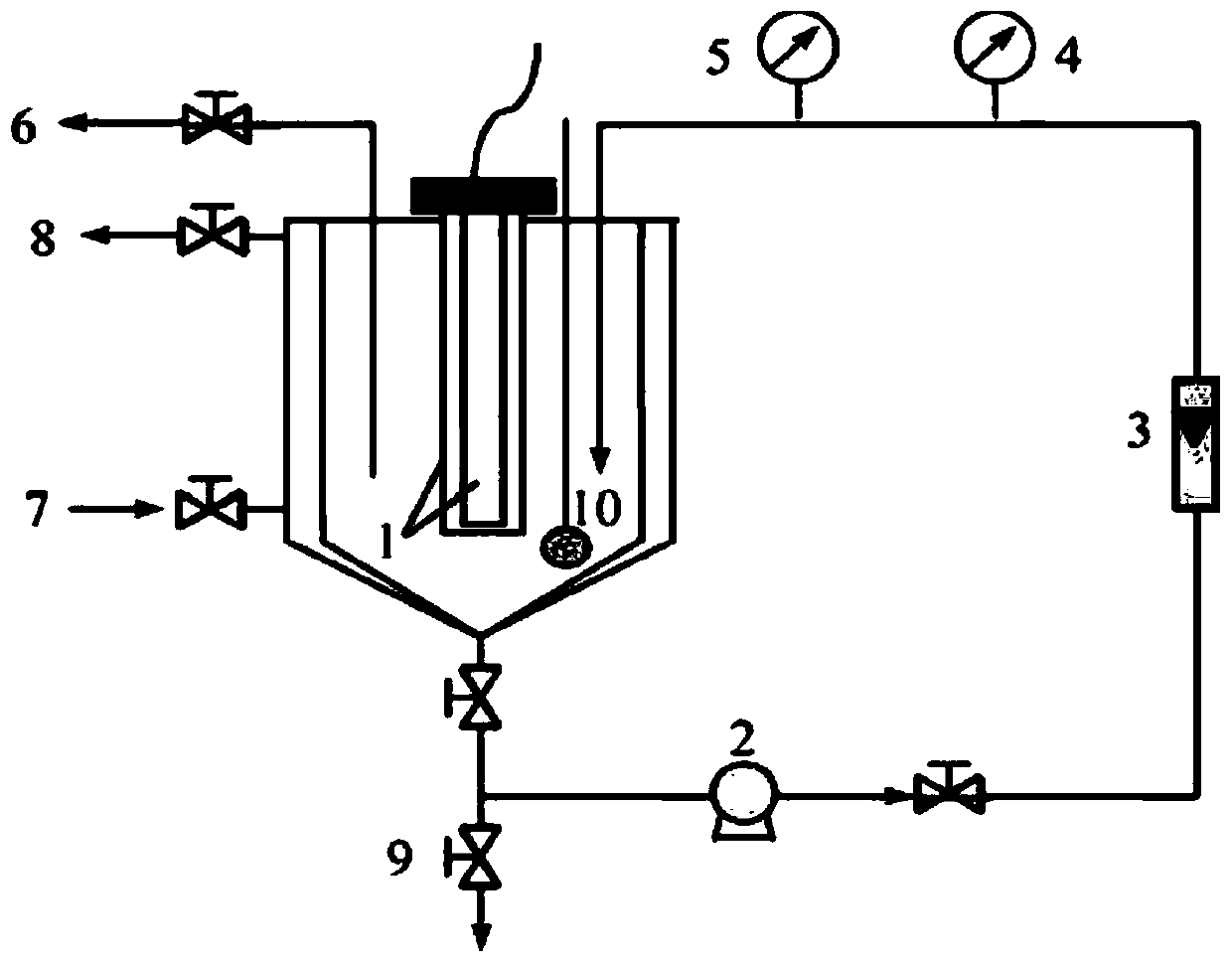

[0045] Embodiment 1, the device diagram is as follows Figure 1-2 As shown, the water sample to be treated is placed in the water tank, the UV lamp tube 1 is placed in the water sample to be treated, the UV lamp tube 1 is covered with a quartz glass sleeve, the aeration tube is also placed in the water sample to be treated, and the aeration An aeration head 10 is provided at the end of the tube. Outside the water tank, there is a cooling water circulation tank, and the cooling water circulation tank is filled with cooling water, which is used to control the reaction temperature of the water sample to be treated and prevent the abnormal temperature rise of the water sample after long-term irradiation of the UV lamp; the cooling water circulation tank is equipped with There are cooling water inlet 7 and cooling water outlet 8. The connection of the water sample to be treated is also provided with a water sample circulation system, including a water sample circulation pipe, and ...

Embodiment 2

[0051] Embodiment two, such as figure 1 , image 3 , the water sample to be treated is placed in the water tank, the UV lamp tube 1 is placed in the water sample to be treated, the UV lamp tube 1 is overcoated with a quartz glass sleeve, and the aeration tube is also placed in the water sample to be treated. An aeration head 10 is provided at the end. Outside the water tank, there is a cooling water circulation tank, and the cooling water circulation tank is filled with cooling water, which is used to control the reaction temperature of the water sample to be treated and prevent the abnormal temperature rise of the water sample after long-term irradiation of the UV lamp; the cooling water circulation tank is equipped with There are cooling water inlet 7 and cooling water outlet 8. The connection of the water sample to be treated is also provided with a water sample circulation system, including a water sample circulation pipe, and the two ends of the water sample circulation...

Embodiment 3

[0058] Embodiment three, a kind of photoreactor, such as Figure 4 As shown, it includes a quartz glass sleeve (with a UV lamp 1 inside), an air pump, a sampling tube 6, an aeration tube and an aeration head 10, a water pump 2, and an air filter.

[0059] The water tank is a 65L tubular stainless steel reactor, and the reactor operates intermittently with complete mixing. The UV lamp adopts a UV lamp with a power of 75W, the wavelength is 254nm, and the UV intensity is controlled to 153 (μW·cm -2 ).

[0060] In this example, air is used as the aeration gas source, and the gas flow rate is 4.8L min -1 , the control group had no aeration, and the water temperature was controlled at room temperature (23±1°C).

[0061] The target pollutant in this example is carbamazepine (a common antiepileptic drug), and the initial concentration is 0.02mM. In this example, H 2 o 2 The dosage of oxidant is 2mM.

[0062] The specific steps for removing carbamazepine by using composite UV a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com